Question:

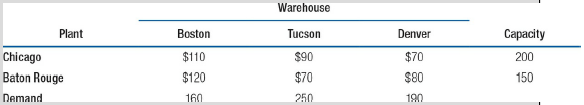

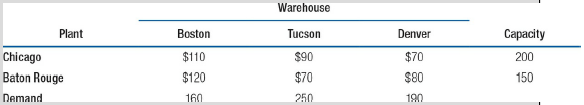

Cool Air Inc. currently manufactures room air conditioners in its Chicago and Baton Rouge plants. The company ships its air conditioners to three warehouses in Boston, Tucson, and Denver. As a result of increasing demand for the company€™s air conditioners, Hari Prasad, the company owner, is planning to build a new plant. He has narrowed down his choices to two possible new locations€”Cleveland and Atlanta. The estimated production capacity of both the new plants will be 300 air conditioners. The total cost per unit of production and shipping from Cleveland to the three warehouses are $50, $60, and $100, and from Atlanta, the costs are $80, $70, and $100. Production capacities for the existing plants and the demand requirements from the three warehouses, as well as the total costs per unit (includes production and shipping costs) for each of the current routes are given in the following table. Which new location (Cleveland or Atlanta) should Hari Prasad select as the location for the company€™s new plant?

Transcribed Image Text:

Warehouse Capacity Plant Boston Tucson Denver Chicago Baton Rouge $110 $70 $90 200 150 $120 $70 $80 190 Demand 160 250