Weldon Hand Tools, one of the most successful of the European hand tool manufacturers, decided to move

Question:

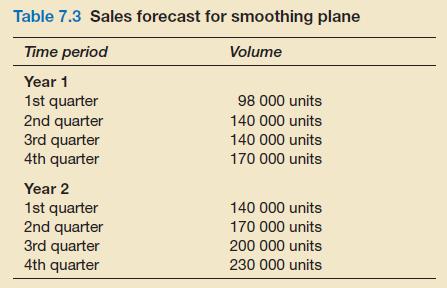

Weldon Hand Tools, one of the most successful of the European hand tool manufacturers, decided to move into the 'woodworking' tools market. Previously its products had been confined to car maintenance, home decorating and general hand tools. One of the first products which it decided to manufacture was a general-purpose 'smoothing plane', a tool which smoothes and shapes wood. Its product designers devised a suitable design and the company's work measurement engineers estimated the time it would take in standard minutes (the time to perform the task plus allowances for rest, etc.) to perform each element in the assembly process. The marketing department also estimated the likely demand (for the whole European market) for the new product. Its sales forecast is shown in Table 7.3.

The marketing department was not totally confident of its forecast, however. 'A substantial proportion of demand is likely to be export sales, which we find difficult to predict.

But whatever demand does turn out to be, we will have to react quickly to meet it. The more we enter these parts of the market, the more we are into impulse buying and the more sales we lose if we don't supply.' This plane was likely to be the first of several similar planes. A further model had already been approved for launch about one year after this and two or three further models were in the planning stage. All the planes were similar, merely varying in length and width.

Designing the manufacturing operation

It has been decided to assemble all planes at one of the company's smaller factory sites where a whole workshop is unused. Within the workshop there is plenty of room for expansion if demand proves higher than forecast. All machining and finishing of parts would be performed at the main factory and the parts shipped to the smaller site where they would be assembled at the available workshop.

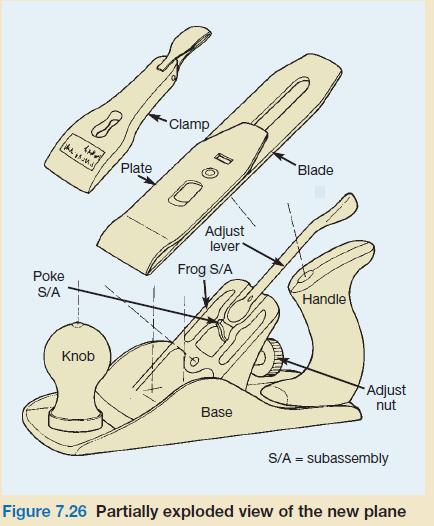

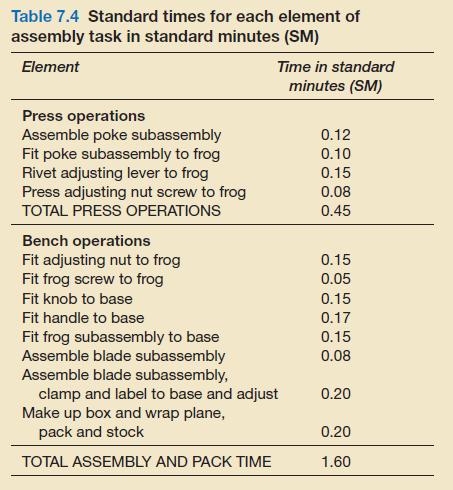

An idea of the assembly task can be gained from the partially exploded view of the product (see Figure 7.26). Table 7.4 gives the ‘standard time’ for each element of the assembly task. Some of the tasks are described as ‘press’ operations. These use a simple mechanical press that applies sufficient force for simple bending, riveting or force-fitting operations. This type of press is not an expensive or sophisticated piece of technology.

Costs and pricing

The standard costing system at the company involves adding a 150 per cent overhead charge to the direct labour cost of manufacturing the product, and the product would retail for the equivalent of around €35 in Europe where most retailers will sell this type of product for about 70–120 per cent more than they buy it from the manufacturer.

Questions

1 How many staff should the company employ?

2 What type of facilities and technology will the company need to buy in order to assemble this product?

3 Design a layout for the assembly operation (to include the fly press work) including the tasks to be performed at each part of the system.

4 How would the layout need to be adjusted as demand for this and similar products builds up?

Step by Step Answer:

Operations Management

ISBN: 9780273708476

5th Edition

Authors: Nigel Slack, Stuart Chambers, Robert Johnston