26 Powerhouse produces capacitors at three locations: Los Angeles, Chicago, and New York. Capacitors are shipped from

Question:

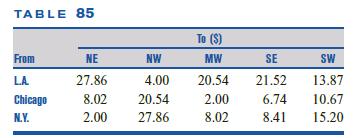

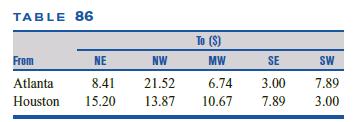

26 Powerhouse produces capacitors at three locations: Los Angeles, Chicago, and New York. Capacitors are shipped from these locations to public utilities in five regions of the country: northeast (NE), northwest (NW), midwest (MW), southeast (SE), and southwest (SW). The cost of producing and shipping a capacitor from each plant to each region of the country is given in Table 85. Each plant has an annual production capacity of 100,000 capacitors. Each year, each region of the country must receive the following number of capacitors: NE, 55,000; NW, 50,000; MW, 60,000; SE, 60,000; SW, 45,000. Powerhouse feels shipping costs are too high, and the company is therefore considering building one or two more production plants. Possible sites are Atlanta and Houston. The costs of producing a capacitor and shipping it to each region of the country are given in Table 86. It costs $3 million (in current dollars) to build a new plant, and operating each plant incurs a fixed cost (in addition to variable shipping and production costs) of

$50,000 per year. A plant at Atlanta or Houston will have the capacity to produce 100,000 capacitors per year.

Assume that future demand patterns and production costs will remain unchanged. If costs are discounted at a rate of 111/9 % per year, how can Powerhouse minimize the present value of all costs associated with meeting current and future demands?

Step by Step Answer:

Operations Research Applications And Algorithms

ISBN: 9780534380588

4th Edition

Authors: Wayne L. Winston