Question

1. An 18m (L)X4.5m (W)X3m(D) aerated grit chamber is designed to treat an average flow of 0.35 m 3 /s and a peak flow of

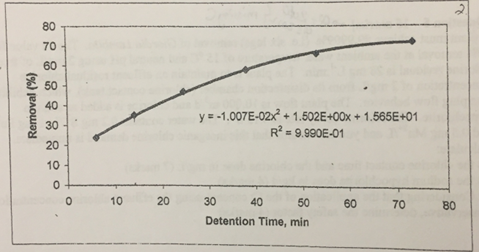

1. An 18m (L)X4.5m (W)X3m(D) aerated grit chamber is designed to treat an average flow of 0.35 m 3 /s and a peak flow of 1.15 m 3 /s. Calculate the Surface overflow rate at both conditions. What are the diameters of the particles (specific gravity 2.65) that will be completely removed and scoured away at both conditions? Assume k = 0.03 and f=0.04. 2. Analysis of laboratory settling data performed on a flocculent suspension yielded the following relationship between the suspended solids (SS) removal efficiency and hydraulic retention time. a. Size a primary clarifier for 50% SS removal for an average daily flow of 10,000 m 3 /d. Use a safety factor of 2.0 for scale-up. If the clarifier is 1.8 m deep, what is the overflow rate? If the influent SS concentration is 250 mg/L, what will the underflow rate from the clarifier be if the suspended solids are compacted to 2% (by wt.)?  3. A town has been directed to upgrade its primary, wastewater treatment plant to a second plant that can meet TSS and BOD 5 limits of 30 mg/L. The primary effluent flow is 12960 m 3 /d, and the primary effluent BOD 5 concentration is 84 mg/L. The BOD 5 of the suspended solids (SS) is estimated as equal to 63% of the SS concentration. In order to utilize an old existing clarifier as a secondary clarifier, the MLVSS must not exceed 2000 mg/L, and the ratio of MLSSA/LVSS is 1.43. The return activated sludge (RAS) SS concentration is 10,000 mg/L. The following kinetic parameters apply: ? max = 2.5d -1 Ks= 100 mg,BOD 5 /L Y=0.5 mgVSS/rngBODs k d = 0.05d -1 Calculate the following: (a) Volume of the aeration tank (b) Mean cell residence time (c) Sludge production rate (kgTSS/d) and sludge wastage rate (kgTSS/d) (d) RAS flow

3. A town has been directed to upgrade its primary, wastewater treatment plant to a second plant that can meet TSS and BOD 5 limits of 30 mg/L. The primary effluent flow is 12960 m 3 /d, and the primary effluent BOD 5 concentration is 84 mg/L. The BOD 5 of the suspended solids (SS) is estimated as equal to 63% of the SS concentration. In order to utilize an old existing clarifier as a secondary clarifier, the MLVSS must not exceed 2000 mg/L, and the ratio of MLSSA/LVSS is 1.43. The return activated sludge (RAS) SS concentration is 10,000 mg/L. The following kinetic parameters apply: ? max = 2.5d -1 Ks= 100 mg,BOD 5 /L Y=0.5 mgVSS/rngBODs k d = 0.05d -1 Calculate the following: (a) Volume of the aeration tank (b) Mean cell residence time (c) Sludge production rate (kgTSS/d) and sludge wastage rate (kgTSS/d) (d) RAS flow

4. Calculate the required surface area and minimum recirculation flow for the treatment of 0.5 million US gallons per day of primary effluent (TBOD = 160 mg/1, soluble BOD = 80 mg/L) to produce an effluent BOD of 20 mg/L with a soluble fraction of 0.5 using a trickling filter packed with plastic media.

K20 = 0.0756 (gal/min) 0.5 ft, n = 0.5, D = 20 ft, T = 15?C min Actual minimum hydraulic loading rate = 0.75 gpm/ft 2 . Assume that the Eckenfelder model fir equation applies for soluble BOO removal and that particulate BOD is physically filtered. What is the BOD loading is the BOD loading in Ib/10 3 ft 3 day

5. A Plant must achieve 99.9999% (i.e. six logs) removal of Giardia Lamblia. The Ct value for 90% removal at the ambient water temperature of 15 ?C and neutral pH using 2 mg/L of free chlorine residual is 28 mg I:1.min. The plant is to maintain an effluent residual chlorine concentration of 2 mg/L from its disinfection chamber (chlorine contact tank), which exhibits a true plug flow behavior. The plant flow is 10,000 red and chlorine is added as sodium hypochlorite. The chlorine decay rate is 0.15 h 1. The water contains 0.2 mg 827L, 1 mg Fe27L, and 0.5 mg Mn /1. and you can assume that this inorganic chlorine demand is immediate. Calculate: (a) the chlorine contact time and the chlorine dose in mg/L (7 marks) (b) the sodium hypochlorite does in kg/d (4 marks) (c) Considering that the application of the Cr concept using the effluent chlorine concentration is conservative, determine the safety factor.

6. (a) Primary sludge containing trickling filter sludge is gravity thickened in a circular tank with a diameter of 12 ft, and side water depth of 10.0 ft. The applied sludge is 2600 gpd with 4.5 % solids (by wt.) and the thickened sludge withdrawn is 1300 gpd at 7.5 % solids (by wt.). The sludge blanket in the tank is 3.0 ft deep. For odour control and to enhance thickening, 45,000 gpd of treated wastewater is pumped to the tank along with the sludge to increase the overflow rate. Calculate the solids loading on the tank, the solids capture, the overflow rate, and the solids retention time in the tank, assuming that all the tank solids are in the sludge blanket. (b) If the thickened sludge from the tank in (a) is anaerobically digested at an SRT of 15 days with a VS destruction efficiency of 50%, calculate the size of the anaerobic digester, and the daily methane production rate. Assume that the volatile fraction of solids is 70%.

Removal (%) 80 70 60 50 40 30 20 10 0 0 10 20 y = -1.007E-02x +1.502E+00x + 1.565E+01 R = 9.990E-01 30 40 50 Detention Time, min 60 70 80

Step by Step Solution

3.51 Rating (168 Votes )

There are 3 Steps involved in it

Step: 1

1 Overflow rate influent flow surface area SA of the chamber 2453 24518 2183 297m 2 Average flow condition 035m 3 s297m 2 1178510 3 ms Peak flow condi...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Document Format ( 2 attachments)

60986d81c8546_28839.pdf

180 KBs PDF File

60986d81c8546_28839.docx

120 KBs Word File

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started