Morton Salt is a subsidiary of 'Morton International, a manufacturer of specialty chemicals, air bags, and salt products. The Morton salt-processing facility in Silver Springs.

Morton Salt is a subsidiary of 'Morton International, a manufacturer of specialty chemicals, air bags, and salt products. The Morton salt-processing facility in Silver Springs. New York between Buffalo and Rochester, is one of six similar Morton salt-processing facilities in the United States.The Silver Springs plant employs about 200 people, ranging from unskilled to skilled. It produces salt products for water conditioning, grocery industrial, and agricultural markets. The grocery business consists of 26-oz, round cans of iodized salt. Although the grocery business represents a relatively small portion of the total output (approximately 15 percent), it the most profitable.

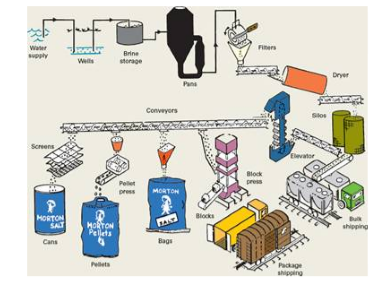

Salt Production:

The basic raw material, salt, is obtained by injecting water into salt caverns that are located some 2.400 feet below the surface, There, the sat deposits dissolve in the water. The resulting brine is pumped to the surface where it is converted into salt crystals. The brine is boiled, and much of the liquid evaporates, leaving salt crystals and some residual moisture, which is removed in a drying process. This process is run continuously for about SIX weeks at a time. Initially salt is produced at the rate of 45 tons per hour. But the rate of output decreases due to scale buildup, so that by the sixth week, output is only 75 percent or the initial rate. At that point, the process is halted to perform maintenance on the equipment and remove the scale, after which, salt production resumes.

The salt is stored in silos until it is needed for production, or it is shipped in bulk to industrial customers. Conveyors move the salt to each of tree four dedicated production areas. One of which is round can production. (See diagram,) The discussion here focuses exclusively on round can production.

Round Can production:

Annual round can production averages roughly 3.8 million cans. Approximately 70 percent of the output is for the Morton label, and the rest is for private label. There are two parallel, high-speed production lines. The two lines share common processes at the beginning of the lines, and then branch out into two identical lines. Each line is capable of producing 9,600 cans per hour (160 cans per minute). The equipment is not flexible, so the production rate is fixed. The operations are completely standardized; the only variable is the brand label that is applied. One line requires 12 production workers, while both lines together can be operated by 18 workers because of the common processes. Workers on the line perform low-skilled, repetitive tasks.

The plant produces both the salt and the cans the salt is packaged in. The cans are essentially a cylinder with a top and a bottom, they are made of cardboard, except for a plastic pour spout in the top. The cylinder portion is formed from two sheers of chip board that are glued together and then rolled into a continuous tube. The glue not only binds the material, it also provides a moisture barrier. The tube is cut in a two-step process: it is first cut into long sections, and those sections are then cut into can-size pieces. The top and bottom pieces for the cans are punches from a continuous strip of cardboard. The separate pieces move along conveyor belts to the lines where the components are assembled into cans and glued. The cans are then filed with salt and the pour spout is added. Finally, the cans are loaded onto pallets and placed into inventory, ready to be shipped to distributors.

Quality

Quality is checked at several points in the production process. Initially, the salt is checked for purity when it is obtained from the wells, Iodine and an anti-caking compound are added to the salt, and their levels are verified using chemical analysis. Crystal size is important In order to achieve the desired size and to remove lumps, the salt is forced through a scraping screen, which can cause very fine pieces of metal to mix with the salt. However, these pieces are effectively removed by magnets that are placed at appropriate points in the process. If, for any reason, the salt is judged to be contaminated, it is diverted to a nonfood product.

Checking the quality of the cans is done primarily by visual inspection, including verifying the assembly operation is correct checking filled cans for correct weight. Inspecting cans to see that labels are properly aligned, and checking to see that plastic pour spouts are correctly attached.

The equipment on the production line is sensitive to misshapen or damaged cans, and frequently jams, causing production delays. This greatly reduces the chance of a defective can getting through the process, but it reduces productivity, and the salt the detective cans must be scrapped The cost of quality is fairly high, owing to the amount of product that is scrapped, the large number of inspectors, and the extensive laboratory testing that is needed.

Production Planning and Inventory:

The plant can sell all of the salt it produces. The job of the production scheduler is to distribute the salt that is stored in the silos to the various production areas, taking into account production capacities in each area and available inventory levels of those products. A Key consideration is to make sure there is sufficient storage capacity in the silos to handle the incoming salt from brine production.

Equipment Maintenance and Repair:

The equipment is 1950s vintage and it requires a fair amount of maintenance to keep it in good working order. Even so, breakdowns occur as parts wear out. The plant has its own tool shop where skilled workers repair parts or make new parts because replacement parts are no longer available for the old equipment. Where would you place salt production in the product?process spectrum?

Water supply Screens H Wells MORTON SALT Cans MORTON Pellets Pellets Brine storage Conveyors Pellet press MORTON JANE Bags Pan Blocks Block press Silos Elevator Package shipping Dryer Buk shipping

Step by Step Solution

3.54 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

There are three types of production processes incl...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Document Format ( 2 attachments)

6090b70346eaf_21881.pdf

180 KBs PDF File

6090b70346eaf_21881.docx

120 KBs Word File

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started