Answered step by step

Verified Expert Solution

Question

1 Approved Answer

1. (10 points) A very large 250 mm-thick iron plate is cast by pouring iron into a sand mould at the temperature 40 C

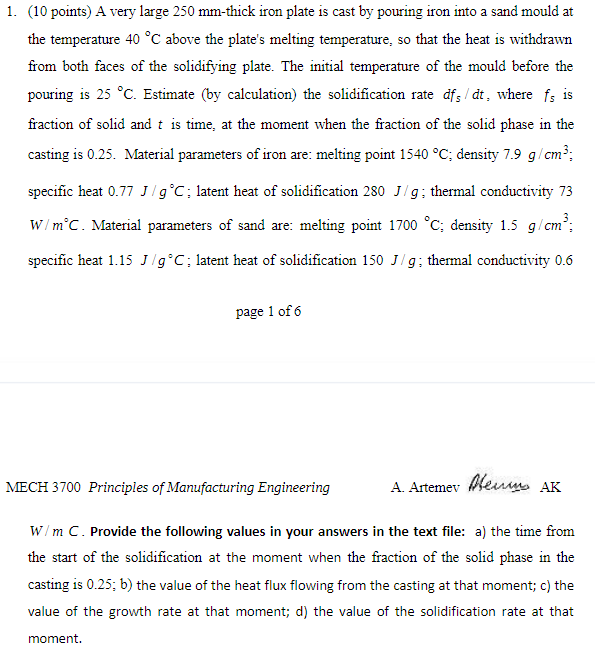

1. (10 points) A very large 250 mm-thick iron plate is cast by pouring iron into a sand mould at the temperature 40 C above the plate's melting temperature, so that the heat is withdrawn from both faces of the solidifying plate. The initial temperature of the mould before the pouring is 25 C. Estimate (by calculation) the solidification rate dfs/dt, where fs is fraction of solid and t is time, at the moment when the fraction of the solid phase in the casting is 0.25. Material parameters of iron are: melting point 1540 C; density 7.9 g/cm: specific heat 0.77 J/gC; latent heat of solidification 280 J/g; thermal conductivity 73 W/mC. Material parameters of sand are: melting point 1700 C; density 1.5 g/cm; specific heat 1.15 J/gC; latent heat of solidification 150 J/g; thermal conductivity 0.6 page 1 of 6 MECH 3700 Principles of Manufacturing Engineering A. Artemev Meu AK W/m C. Provide the following values in your answers in the text file: a) the time from the start of the solidification at the moment when the fraction of the solid phase in the casting is 0.25; b) the value of the heat flux flowing from the casting at that moment; c) the value of the growth rate at that moment; d) the value of the solidification rate at that moment.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started