1. [10 points] Solve the problem manually. Briefly describe the strategy you used to develop your solution, and your final production plan. Calculate the number

1. [10 points] Solve the problem manually. Briefly describe the strategy you used to develop your solution, and your final production plan. Calculate the number of overtime hours the company would need to pay should your solution be implemented.

2. [20 points] Define a (computational) solution representation for the problem that you can later implement as a Python data structure (i.e. a list, a matrix, a dictionary, etc.). Describe your solution representation in detail. If it is a list, for instance, explain precisely what each entry in the list represents. Use this representation to describe your solution from the previous question. For the subsequent part of this assignment, please download the file HomeWork4.py available in Canvas, and develop your code using this file as a template.

3. [30 points] Develop a Python function named CalculateOvertime(S, E, R, Solution), that reads four inputs: (i) the list S of the standard times, (ii) the list E with the efficiencies, (ii) the list R with the production requirements, and (iv) a Solution to the problem (using your solution representation). The function must return the number of (integer) overtime hours in the solution passes as a parameter.

4. [40 points] Develop a Python function named Greedy(S, E, R), that reads three inputs: (i) the list S of the standard times, (ii) the list E with the efficiencies, and (ii) the list R with the production requirements. The function must return a Solution to the problem using your solution representation.

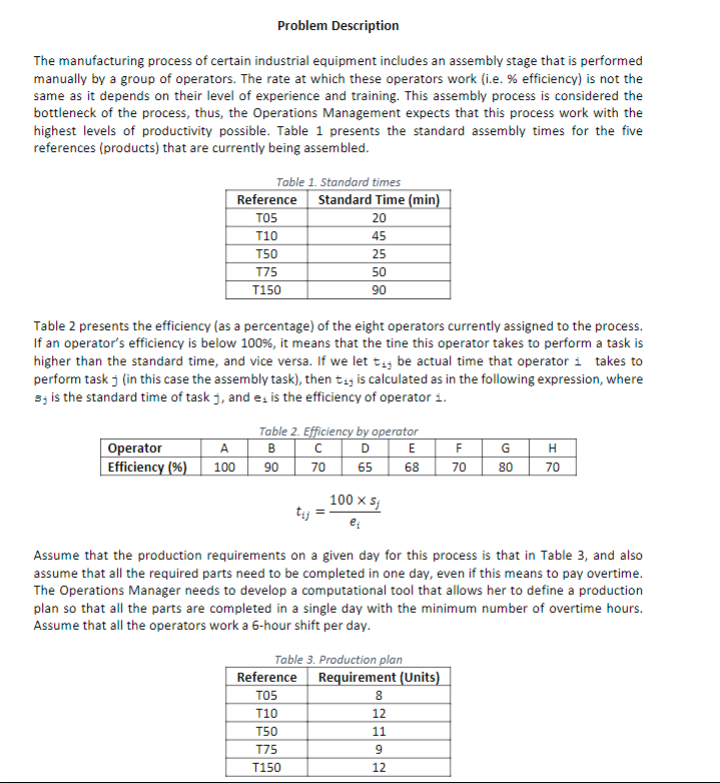

Problem Description The manufacturing process of certain industrial equipment includes an assembly stage that is performed manually by a group of operators. The rate at which these operators work (ie, % efficiency) is not the same as it depends on their level of experience and training. This assembly process is considered the bottleneck of the process, thus, the Operations Management expects that this process work with the highest levels of productivity possible. Table 1 presents the standard assembly times for the five references (products) that are currently being assembled Table 1. Standard times Reference Standard Time (min TO5 T10 TS0 T75 T150 20 45 25 50 Table 2 presents the efficiency (as a percentage) of the eight operators currently assigned to the process If an operator's efficiency is below 100%, it means that the tine this operator takes to perform a task is higher than the standard time, and vice versa. If we let be actual time that operator i takes to perform task j (in this case the assembly task), then t is calculated as in the following expression, where s the standard time of task j, and e is the efficiency of operator i Table 2. Efficie operator Operator Efficien 100 90 70 65 68 70 80 70 100 x S Assume that the production requirements on a given day for this process is that in Table 3, and also assume that all the required parts need to be completed in one day, even if this means to pay overtime The Operations Manager needs to develop a computational tool that allows her to define a production plan so ththe parts are completed in a single day with the minimum number of overtime hours. Assume that all the operators work a 6-hour shift per day Table 3. Production plan Reference Requirement (Units TO5 T10 T50 T75 T150 12 12 Problem Description The manufacturing process of certain industrial equipment includes an assembly stage that is performed manually by a group of operators. The rate at which these operators work (ie, % efficiency) is not the same as it depends on their level of experience and training. This assembly process is considered the bottleneck of the process, thus, the Operations Management expects that this process work with the highest levels of productivity possible. Table 1 presents the standard assembly times for the five references (products) that are currently being assembled Table 1. Standard times Reference Standard Time (min TO5 T10 TS0 T75 T150 20 45 25 50 Table 2 presents the efficiency (as a percentage) of the eight operators currently assigned to the process If an operator's efficiency is below 100%, it means that the tine this operator takes to perform a task is higher than the standard time, and vice versa. If we let be actual time that operator i takes to perform task j (in this case the assembly task), then t is calculated as in the following expression, where s the standard time of task j, and e is the efficiency of operator i Table 2. Efficie operator Operator Efficien 100 90 70 65 68 70 80 70 100 x S Assume that the production requirements on a given day for this process is that in Table 3, and also assume that all the required parts need to be completed in one day, even if this means to pay overtime The Operations Manager needs to develop a computational tool that allows her to define a production plan so ththe parts are completed in a single day with the minimum number of overtime hours. Assume that all the operators work a 6-hour shift per day Table 3. Production plan Reference Requirement (Units TO5 T10 T50 T75 T150 12 12Step by Step Solution

There are 3 Steps involved in it

Step: 1

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started