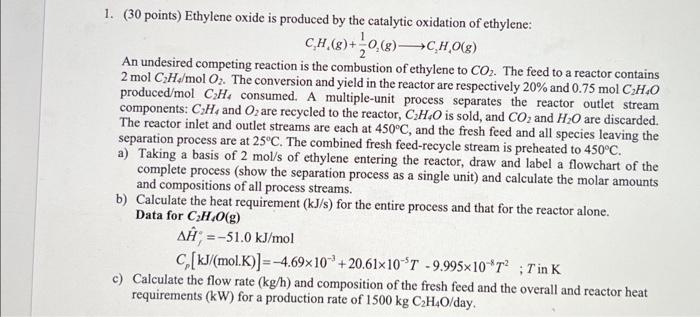

1. ( 30 points) Ethylene oxide is produced by the catalytic oxidation of ethylene: C2H4(g)+21O2(g)C2H4O(g) An undesired competing reaction is the combustion of ethylene to CO2. The feed to a reactor contains 2molC2H4/molO2. The conversion and yield in the reactor are respectively 20% and 0.75mol2C4O produced /molC2H4 consumed. A multiple-unit process separates the reactor outlet stream components: C2H4 and O2 are recycled to the reactor, C2H4O is sold, and CO2 and H2O are discarded. The reactor inlet and outlet streams are each at 450C, and the fresh feed and all species leaving the separation process are at 25C. The combined fresh feed-recycle stream is preheated to 450C. a) Taking a basis of 2mol/s of ethylene entering the reactor, draw and label a flowchart of the complete process (show the separation process as a single unit) and calculate the molar amounts and compositions of all process streams. b) Calculate the heat requirement (kJ/s) for the entire process and that for the reactor alone. Data for C2H4O(g) H^;=51.0kJ/molCp[kJ/(mol.K)]=4.69103+20.61105T9.995108T2;TinK c) Calculate the flow rate (kg/h) and composition of the fresh feed and the overall and reactor heat requirements ( kW ) for a production rate of 1500kgC2H4O/ day. 1. ( 30 points) Ethylene oxide is produced by the catalytic oxidation of ethylene: C2H4(g)+21O2(g)C2H4O(g) An undesired competing reaction is the combustion of ethylene to CO2. The feed to a reactor contains 2molC2H4/molO2. The conversion and yield in the reactor are respectively 20% and 0.75mol2C4O produced /molC2H4 consumed. A multiple-unit process separates the reactor outlet stream components: C2H4 and O2 are recycled to the reactor, C2H4O is sold, and CO2 and H2O are discarded. The reactor inlet and outlet streams are each at 450C, and the fresh feed and all species leaving the separation process are at 25C. The combined fresh feed-recycle stream is preheated to 450C. a) Taking a basis of 2mol/s of ethylene entering the reactor, draw and label a flowchart of the complete process (show the separation process as a single unit) and calculate the molar amounts and compositions of all process streams. b) Calculate the heat requirement (kJ/s) for the entire process and that for the reactor alone. Data for C2H4O(g) H^;=51.0kJ/molCp[kJ/(mol.K)]=4.69103+20.61105T9.995108T2;TinK c) Calculate the flow rate (kg/h) and composition of the fresh feed and the overall and reactor heat requirements ( kW ) for a production rate of 1500kgC2H4O/ day