Answered step by step

Verified Expert Solution

Question

1 Approved Answer

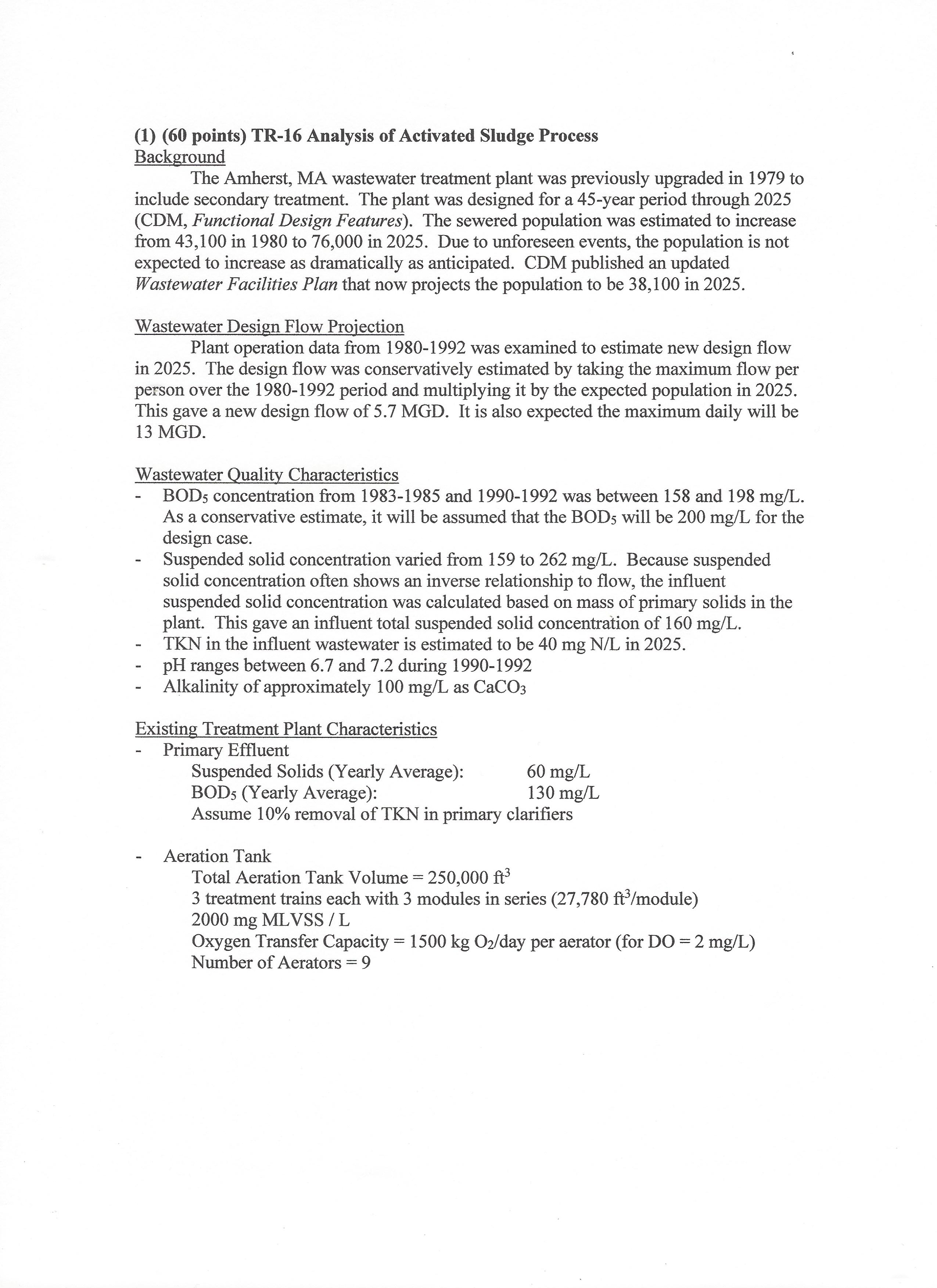

(1) (60 points) TR-16 Analysis of Activated Sludge Process Background The Amherst, MA wastewater treatment plant was previously upgraded in 1979 to include secondary

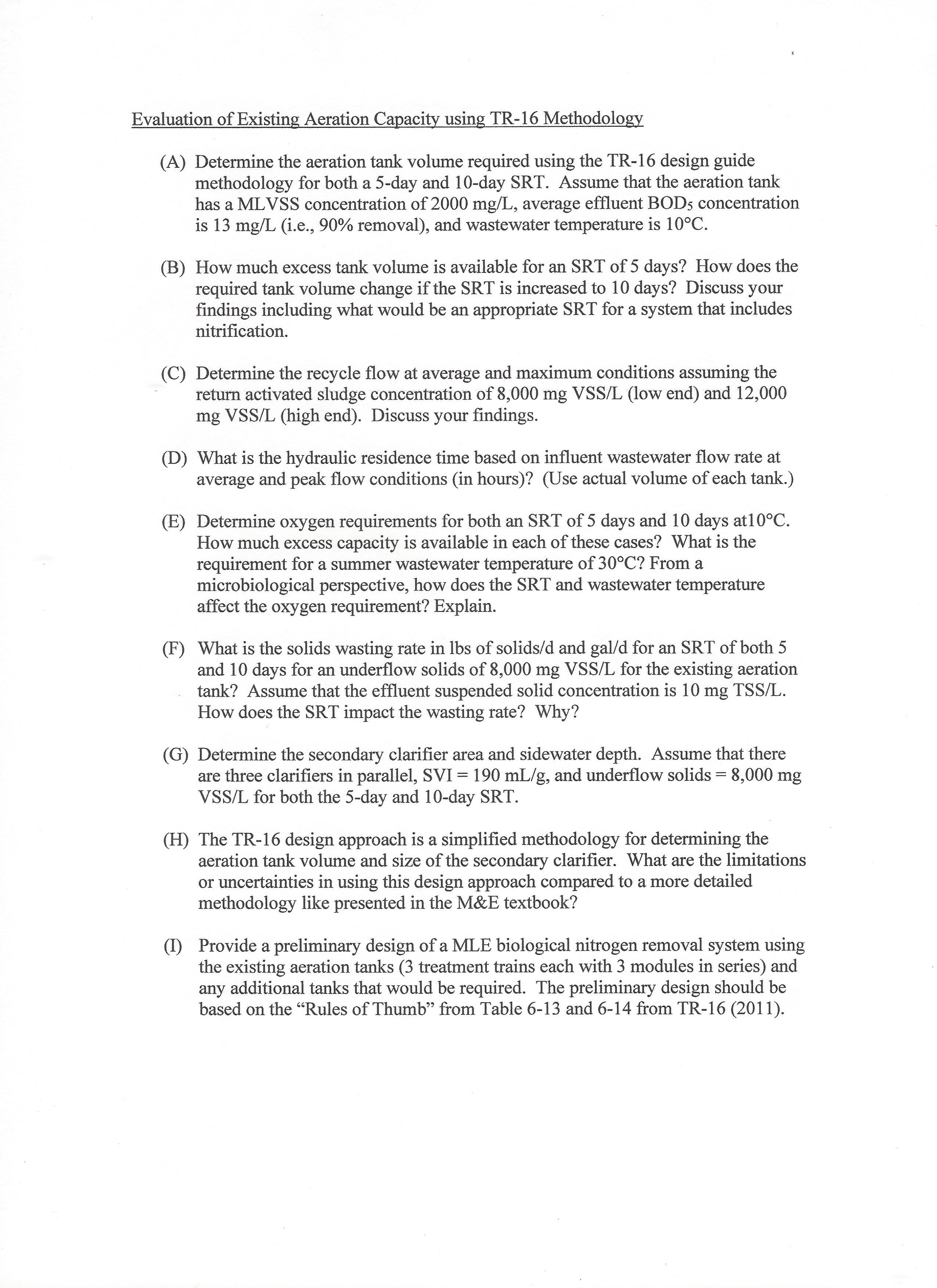

(1) (60 points) TR-16 Analysis of Activated Sludge Process Background The Amherst, MA wastewater treatment plant was previously upgraded in 1979 to include secondary treatment. The plant was designed for a 45-year period through 2025 (CDM, Functional Design Features). The sewered population was estimated to increase from 43,100 in 1980 to 76,000 in 2025. Due to unforeseen events, the population is not expected to increase as dramatically as anticipated. CDM published an updated Wastewater Facilities Plan that now projects the population to be 38,100 in 2025. Wastewater Design Flow Projection Plant operation data from 1980-1992 was examined to estimate new design flow in 2025. The design flow was conservatively estimated by taking the maximum flow per person over the 1980-1992 period and multiplying it by the expected population in 2025. This gave a new design flow of 5.7 MGD. It is also expected the maximum daily will be 13 MGD. Wastewater Quality Characteristics BOD5 concentration from 1983-1985 and 1990-1992 was between 158 and 198 mg/L. As a conservative estimate, it will be assumed that the BOD5 will be 200 mg/L for the design case. Suspended solid concentration varied from 159 to 262 mg/L. Because suspended solid concentration often shows an inverse relationship to flow, the influent suspended solid concentration was calculated based on mass of primary solids in the plant. This gave an influent total suspended solid concentration of 160 mg/L. TKN in the influent wastewater is estimated to be 40 mg N/L in 2025. pH ranges between 6.7 and 7.2 during 1990-1992 Alkalinity of approximately 100 mg/L as CaCO3 Existing Treatment Plant Characteristics Primary Effluent Suspended Solids (Yearly Average): 60 mg/L 130 mg/L BOD5 (Yearly Average): Assume 10% removal of TKN in primary clarifiers Aeration Tank Total Aeration Tank Volume = 250,000 ft 3 treatment trains each with 3 modules in series (27,780 ft/module) 2000 mg MLVSS/L Oxygen Transfer Capacity = 1500 kg O/day per aerator (for DO = 2 mg/L) Number of Aerators = 9 Evaluation of Existing Aeration Capacity using TR-16 Methodology (A) Determine the aeration tank volume required using the TR-16 design guide methodology for both a 5-day and 10-day SRT. Assume that the aeration tank has a MLVSS concentration of 2000 mg/L, average effluent BOD5 concentration is 13 mg/L (i.e., 90% removal), and wastewater temperature is 10C. (B) How much excess tank volume is available for an SRT of 5 days? How does the required tank volume change if the SRT is increased to 10 days? Discuss your findings including what would be an appropriate SRT for a system that includes nitrification. (C) Determine the recycle flow at average and maximum conditions assuming the return activated sludge concentration of 8,000 mg VSS/L (low end) and 12,000 mg VSS/L (high end). Discuss your findings. (D) What is the hydraulic residence time based on influent wastewater flow rate at average and peak flow conditions (in hours)? (Use actual volume of each tank.) (E) Determine oxygen requirements for both an SRT of 5 days and 10 days at 10C. How much excess capacity is available in each of these cases? What is the requirement for a summer wastewater temperature of 30C? From a microbiological perspective, how does the SRT and wastewater temperature affect the oxygen requirement? Explain. (F) What is the solids wasting rate in lbs of solids/d and gal/d for an SRT of both 5 and 10 days for an underflow solids of 8,000 mg VSS/L for the existing aeration tank? Assume that the effluent suspended solid concentration is 10 mg TSS/L. How does the SRT impact the wasting rate? Why? (G) Determine the secondary clarifier area and sidewater depth. Assume that there are three clarifiers in parallel, SVI = 190 mL/g, and underflow solids = 8,000 mg VSS/L for both the 5-day and 10-day SRT. (H) The TR-16 design approach is a simplified methodology for determining the aeration tank volume and size of the secondary clarifier. What are the limitations or uncertainties in using this design approach compared to a more detailed methodology like presented in the M&E textbook? (I) Provide a preliminary design of a MLE biological nitrogen removal system using the existing aeration tanks (3 treatment trains each with 3 modules in series) and any additional tanks that would be required. The preliminary design should be based on the "Rules of Thumb" from Table 6-13 and 6-14 from TR-16 (2011).

Step by Step Solution

★★★★★

3.32 Rating (158 Votes )

There are 3 Steps involved in it

Step: 1

Given that a Using TR16 methodology Determine aeration tank volume for 5day and 10day SRT considering MLVSS concentration average effluent BOD5 concentration and wastewater temperature b Excess tank v...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started