Answered step by step

Verified Expert Solution

Question

1 Approved Answer

1 9 5 of 6 9 5 t industrial chemical soda ash, N a 2 C O 3 , is produced from lime , salt,

of

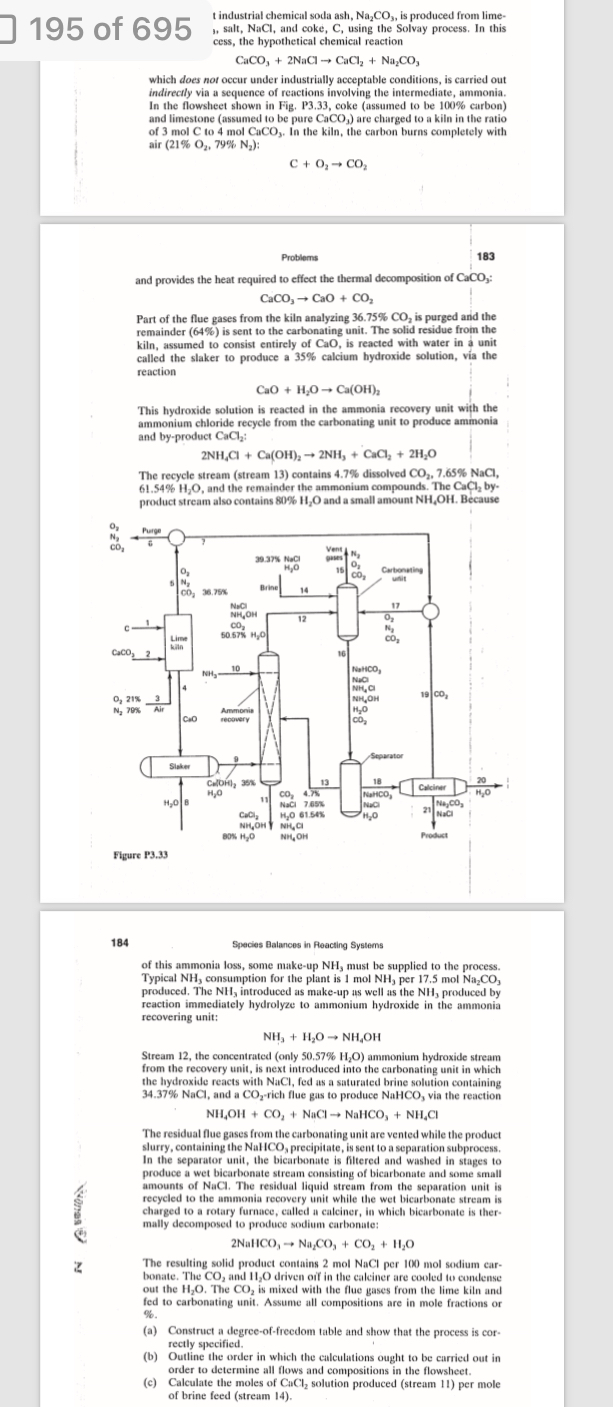

t industrial chemical soda ash, is produced from lime salt, NaCl, and coke, using the Solvay process. In this cess, the hypothetical chemical reaction

NaCl

which does not occur under industrially acceptable conditions, is carried out indirectly via a sequence of reactions involving the intermediate, ammonia. In the flowsheet shown in Fig. P coke assumed to be carbon and limestone assumed to be pure are charged to a kiln in the ratio of molCto In the kiln, the carbon burns completely with air :

Problems

and provides the heat required to effect the thermal decomposition of :

CaO

Part of the flue gases from the kiln analyzing is purged and the remainder is sent to the carbonating unit. The solid residue from the kiln, assumed to consist entirely of CaO, is reacted with water in a unit called the slaker to produce a calcium hydroxide solution, via the reaction

CaO

This hydroxide solution is reacted in the ammonia recovery unit with the ammonium chloride recycle from the carbonating unit to produce ammonia and byproduct :

The recycle stream stream contains dissolved NaCl, and the remainder the ammonium compounds. The byproduct stream also contains and a small amount Because

Species Balances in Reacting Systems

of this ammonia loss, some makeup must be supplied to the process. produced. The introduced as makeup as well as the produced by reaction immediately hydrolyze to ammonium hydroxide in the ammonia recovering unit:

Stream the concentrated only ammonium hydroxide stream from the recovery unit, is next introduced into the carbonating unit in which the hydroxide reacts with NaCl, fed as a saturated brine solution containing O rich flue gas to produce via the reaction

NaCl

The residual flue gases from the carbonating unit are vented while the product slurry, containing the NaHCO, precipitate, is sent to a separation subprocess. In the separator unit, the bicarbonate is filtered and washed in stages to produce a wet bicarbonate stream consisting of bicarbonate and some small amounts of NaCl. The residual liquid stream from the separation unit is recycled to the ammonia recovery unit while the wet bicarbonate stream is charged to a rotary furnace, called a calciner, in which bicarbonate is thermally decomposed to produce sodium carbonate:

The resulting solid product contains molNaCl per mol sodium carbonate. The and driven off in the calciner are cooled to condense out the The is mixed with the flue gases from the lime kiln and fed to carbonating unit. Assume all compositions are in mole fractions or

a Construct a degreeoffreedom table and show that the process is correctly specified.

b Outline the order in which the calculations ought to be carried out in order to determine all flows and compositions in the flowsheet.

c Calculate the moles of solution produced stream per mole of brine feed stream

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started