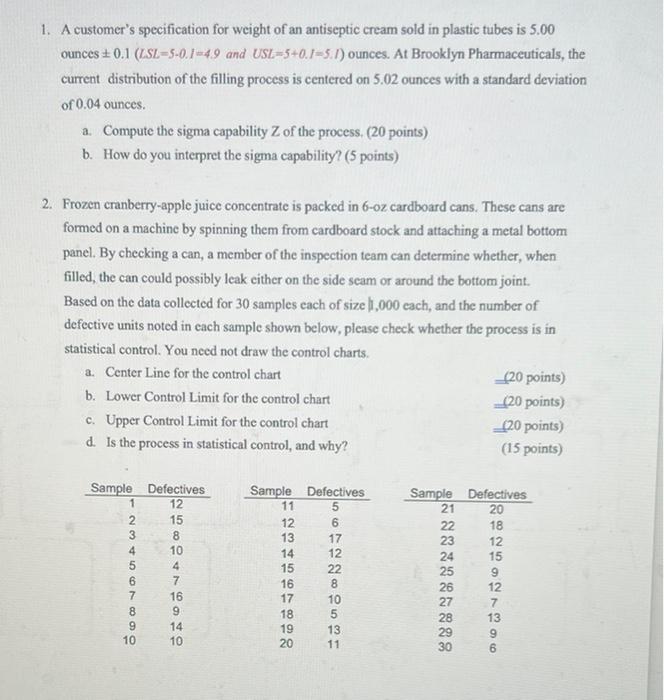

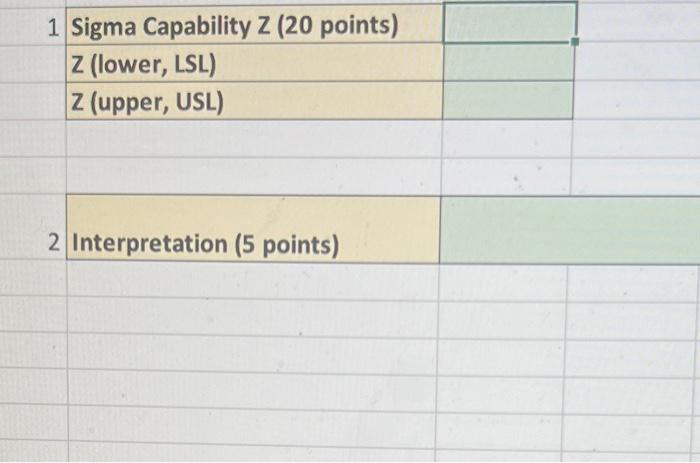

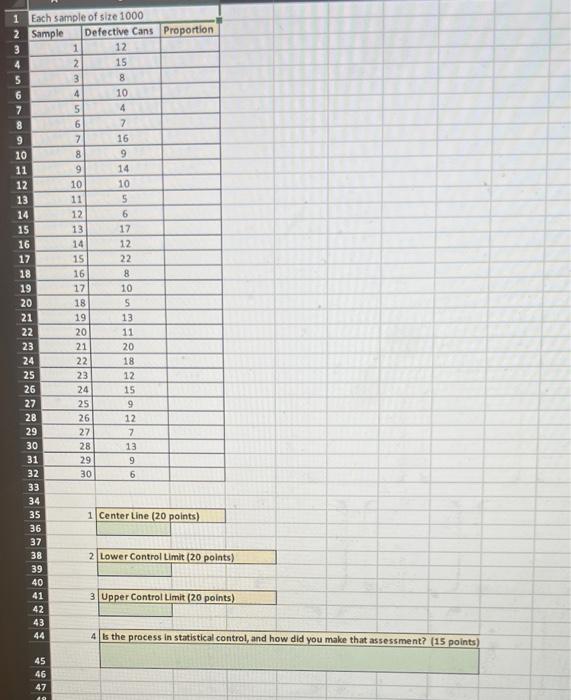

1. A customer's specification for weight of an antiseptic cream sold in plastic tubes is 5.00 ounces 0.1 ( LSL=50.1=4.9 and USL =5+0.I=5.I) ounces. At Brooklyn Pharmaceuticals, the current distribution of the filling process is centered on 5.02 ounces with a standard deviation of 0.04 ounces. a. Compute the sigma capability Z of the process. (20 points) b. How do you interpret the sigma capability? (5 points) 2. Frozen cranberry-apple juice concentrate is packed in 6-0z cardboard cans. These cans are formed on a machine by spinning them from cardboard stock and attaching a metal bottom panel. By checking a can, a member of the inspection team can determine whether, when filled, the can could possibly leak cither on the side seam or around the bottom joint. Based on the data collected for 30 samples each of size 1i,000 each, and the number of defective units noted in each sample shown below, please check whether the process is in statistical control. You need not draw the control charts. a. Center Line for the control chart (20 points) b. Lower Control Limit for the control chart (20 points) c. Upper Control Limit for the control chart (20 points) d. Is the process in statistical control, and why? (15 points) 2 Interpretation (5 points) 1 Each sample of size 1000 1 Center tine (20 points) 1. A customer's specification for weight of an antiseptic cream sold in plastic tubes is 5.00 ounces 0.1 ( LSL=50.1=4.9 and USL =5+0.I=5.I) ounces. At Brooklyn Pharmaceuticals, the current distribution of the filling process is centered on 5.02 ounces with a standard deviation of 0.04 ounces. a. Compute the sigma capability Z of the process. (20 points) b. How do you interpret the sigma capability? (5 points) 2. Frozen cranberry-apple juice concentrate is packed in 6-0z cardboard cans. These cans are formed on a machine by spinning them from cardboard stock and attaching a metal bottom panel. By checking a can, a member of the inspection team can determine whether, when filled, the can could possibly leak cither on the side seam or around the bottom joint. Based on the data collected for 30 samples each of size 1i,000 each, and the number of defective units noted in each sample shown below, please check whether the process is in statistical control. You need not draw the control charts. a. Center Line for the control chart (20 points) b. Lower Control Limit for the control chart (20 points) c. Upper Control Limit for the control chart (20 points) d. Is the process in statistical control, and why? (15 points) 2 Interpretation (5 points) 1 Each sample of size 1000 1 Center tine (20 points)