Answered step by step

Verified Expert Solution

Question

1 Approved Answer

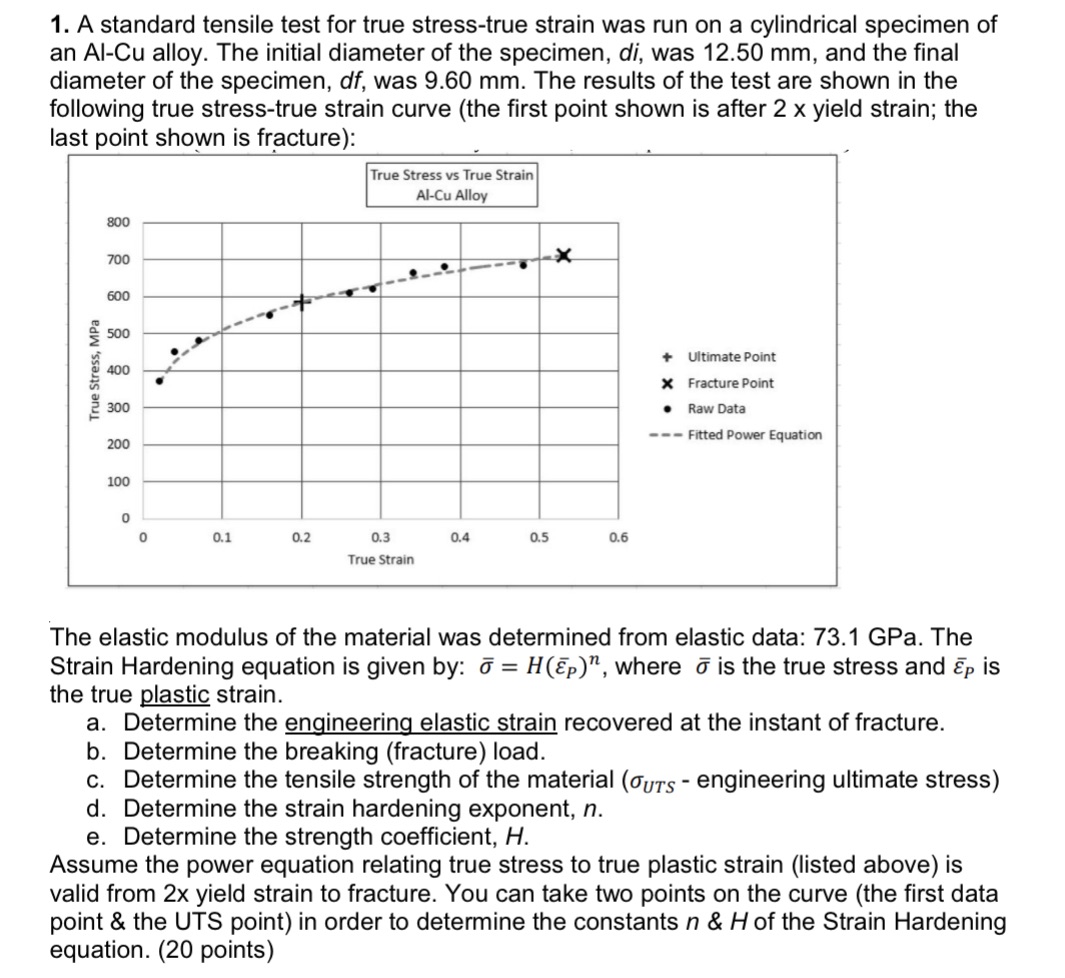

1. A standard tensile test for true stress-true strain was run on a cylindrical specimen of an Al-Cu alloy. The initial diameter of the

1. A standard tensile test for true stress-true strain was run on a cylindrical specimen of an Al-Cu alloy. The initial diameter of the specimen, di, was 12.50 mm, and the final diameter of the specimen, df, was 9.60 mm. The results of the test are shown in the following true stress-true strain curve (the first point shown is after 2 x yield strain; the last point shown is fracture): True Stress vs True Strain Al-Cu Alloy True Stress, MPa 800 700 600 500 400 300 200 00 100 0 0 0.1 0.2 0.3 0.4 0.5 0.6 True Strain + Ultimate Point Fracture Point Raw Data ---Fitted Power Equation The elastic modulus of the material was determined from elastic data: 73.1 GPa. The Strain Hardening equation is given by: = H(p)", where is the true stress and p is the true plastic strain. a. Determine the engineering elastic strain recovered at the instant of fracture. b. Determine the breaking (fracture) load. c. Determine the tensile strength of the material (UTS - engineering ultimate stress) d. Determine the strain hardening exponent, n. e. Determine the strength coefficient, H. Assume the power equation relating true stress to true plastic strain (listed above) is valid from 2x yield strain to fracture. You can take two points on the curve (the first data point & the UTS point) in order to determine the constants n & H of the Strain Hardening equation. (20 points)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started