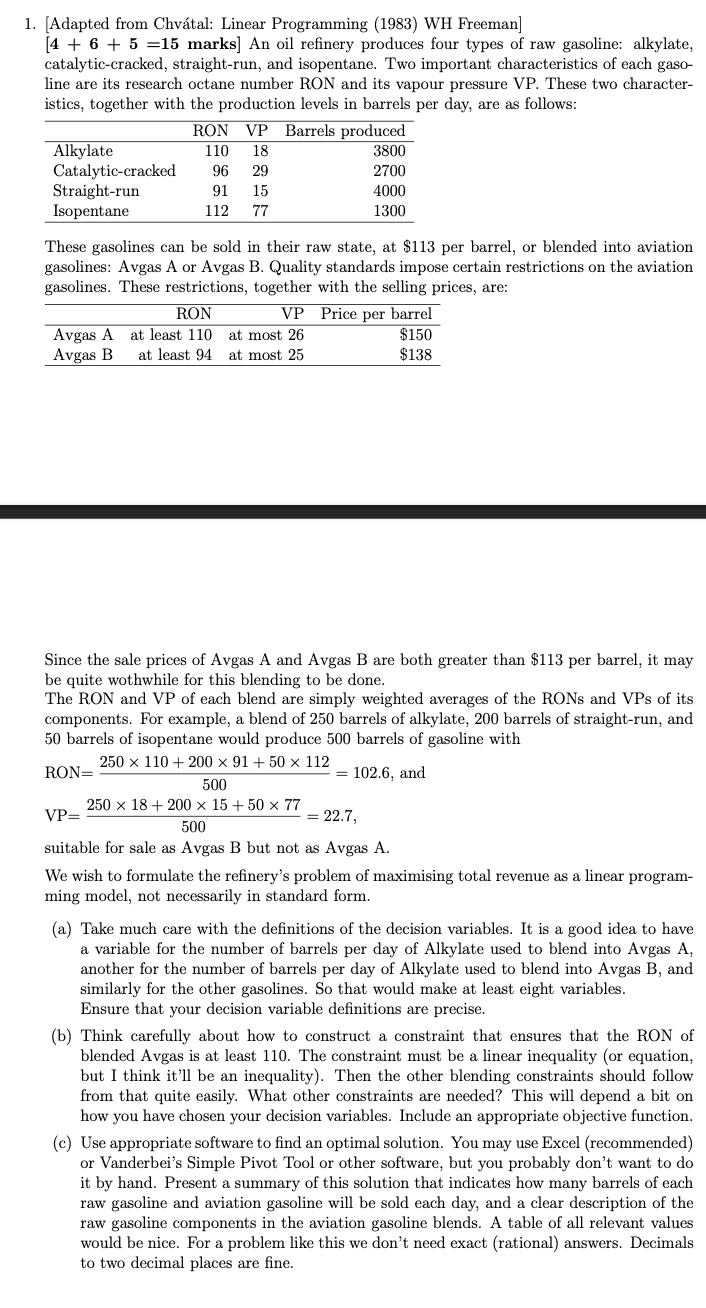

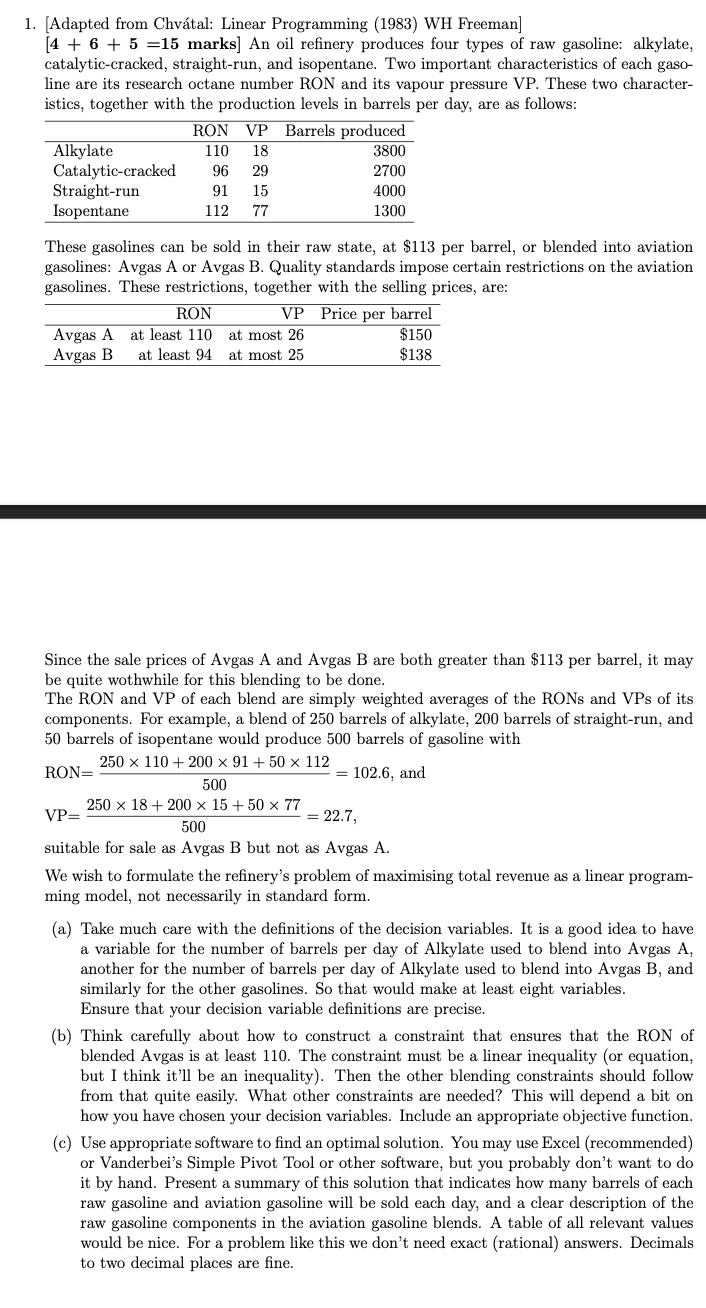

1. (Adapted from Chvtal: Linear Programming (1983) WH Freeman] [4 + 6 + 5 =15 marks] An oil refinery produces four types of raw gasoline: alkylate, catalytic-cracked, straight-run, and isopentane. Two important characteristics of each gaso- line are its research octane number RON and its vapour pressure VP. These two character- istics, together with the production levels in barrels per day, are as follows: RON VP Barrels produced Alkylate 110 3800 Catalytic-cracked 96 2700 Straight-run 4000 Isopentane 112 77 1300 18 29 15 91 These gasolines can be sold in their raw state, at $113 per barrel, or blended into aviation gasolines: Avgas A or Avgas B. Quality standards impose certain restrictions on the aviation gasolines. These restrictions, together with the selling prices, are: RON VP Price per barrel Avgas A at least 110 at most 26 $150 Avgas B at least 94 at most 25 $138 Since the sale prices of Avgas A and Avgas B are both greater than $113 per barrel, it may be quite wothwhile for this blending to be done. The RON and VP of each blend are simply weighted averages of the RONs and VPs of its components. For example, a blend of 250 barrels of alkylate, 200 barrels of straight-run, and 50 barrels of isopentane would produce 500 barrels of gasoline with 250 x 110 + 200 x 91 + 50 x 112 RON= = 102.6, and 500 VP= 250 x 18+ 200 x 15 + 50 x 77 = 22.7, 500 suitable for sale as Avgas B but not as Avgas A. We wish to formulate the refinery's problem of maximising total revenue as a linear program- ming model, not necessarily in standard form. (a) Take much care with the definitions of the decision variables. It is a good idea to have a variable for the number of barrels per day of Alkylate used to blend into Avgas A, another for the number of barrels per day of Alkylate used to blend into Avgas B, and similarly for the other gasolines. So that would make at least eight variables. Ensure that your decision variable definitions are precise. (b) Think carefully about how to construct a constraint that ensures that the RON of blended Avgas is at least 110. The constraint must be a linear inequality (or equation, but I think it'll be an inequality). Then the other blending constraints should follow from that quite easily. What other constraints are needed? This will depend a bit on how you have chosen your decision variables. Include an appropriate objective function. (c) Use appropriate software to find an optimal solution. You may use Excel (recommended) or Vanderbei's Simple Pivot Tool or other software, but you probably don't want to do it by hand. Present a summary of this solution that indicates how many barrels of each raw gasoline and aviation gasoline will be sold each day, and a clear description of the raw gasoline components in the aviation gasoline blends. A table of all relevant values would be nice. For a problem like this we don't need exact (rational) answers. Decimals to two decimal places are fine