1. As Victoria show me how much glass do you think will be ordered jn the bext two years. There are two sizes in the clear and two sizes for the Low Energy.

2. Would you take advantage of the volume discounts Why or why not Can you quantify these with holding cost and ordering cost

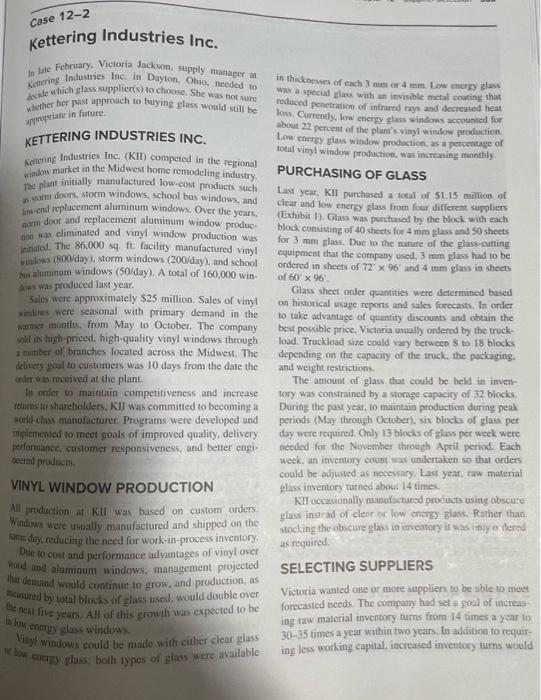

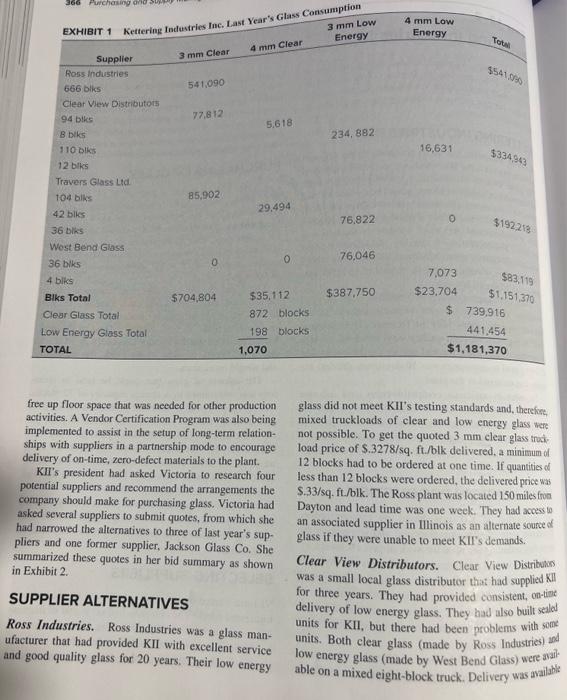

In lale February. Victoria Jackson, supply manaper at in thicknesses of exch 3 num or 4 mm. Low energy glass sertering tadustries Inc. in Dayton, Ohio, needed io was a special glass with an invisible metal coating that woide ther ber past approach to buying glass would sill be reduced penetration of infared ays and decreseded heate ippropriate in furore. KETTERING INDUSTRIES INC. Low energy glas window productioa as a percentage of Nettering Industries Ine. (KII) competed in the regional window market in the Midwest home remodeling industry. PURCHASING OF GLASS the plant initially manufactured low-cost products such Las yeat, KII purchased a lotal of 51.15 million of an warm dons, storm windows, school bus windows, and clear and low energy glass from foer different suppliers lam-end replacement aluminum windows. Over the years, (Exhibit 1). Glass was porchaved by the block with each asm door and replacement aluminum window produe- block consising of 40 shoets for 4 mm glass and 50 sheets tion uas eliminated and vinyl window production was for 3mm glass. Doe to the mature of the glass-cutting inritated. The 86,000 sq. ft. facility manufactured vinyl equipment that the company uset, 3 mm glass had to be viadoma (800/day). storm windows (200/day), and school ordered in sheets of 7296 and 4mm glass in sheets bus aluminum windows (50/day). A total of 160,000 win- of 6096 ) Sis was produced last year. Sales were approximately $25 million. Sales of viny sialows were seasonal with primary demand in the on historical usage reporrs and sales forecasts. In onder warmer moaths. from May to October. The company to take advantage of quantity discounts and obtain the wild its high-priced, high-quality vinyl windows through bed possible price. Victoria unually ondered by the trucka nurnber of brenches focated across the Midwest. The load. Trucklosd size coald vary between 8 to 18 blocks depending on the copacity of the truck, the paskaging. and weight restristions. (miter nas received at the plant. Tn ender to maintain competitiveness and increase tory was constrained by a stonge capaciry of 32 blocks: returns ta shareholdens, KII was committed to becoming a During the past year, to maintain production during peak sorld-chass manufacturer. Programs were developed and periods (May through October), six blocks of glass per implemened to meet poals of improved qualify, delivery day were roquired. Only 13 blods of glass per week were peformance, customer responsiveness, and better engi- needed for the November through April period. Each aeced products week, an inventory conat was undertaken so that orders coald be adjusted as necessary. Last year, raw material VINYL WINDOW PRODUCTION glass inventory turned abous 14 times. All production at KII was based on custom orders._. KAl occasionally masufactured products using obscure Windous were usially manufactured and shipped on the Giass instead of cles or low eneryy glass. Rather than. sme-day, redocing the need for work-in-processinventory stocling the obseture glass in inventory it was toly ordered Dete to cost and performance advantages of viayl over. as tequired. kond and aluminum windows, mangement projected SELECTING SUPPLIERS that dentand would continue to grow, and production, as teasured by total blocks of glass used, swould double over the nexi five years. All of this growih was expected to be las enerey gloss windowx. Viyyf windows could be mide with either clear glass 30 - 35 times a year within two years. In addifico to requirHow crergy glass: both types of glass were available- ing less working capital, increased inventory tums would free up floor space that was needed for other production glass did not meet KII's testing standards and, therefroe, activities. A Vendor Certification Program was also being mixed truckloads of clear and low energy glass were implemented to assist in the setup of long-term relation- not possible. To get the quoted 3mm clear glass tratiships with suppliers in a partnership mode to encounge load price of $.3278/sq. ft/blk delivered, a minimum of delivery of on-time, zero-defect materials to the plant. 12 blocks had to be ordered at one time. If quantitio of KII's president had asked Victoria to research four less than 12 blocks were ordered, the delivered price ws potential suppliers and recommend the arrangements the $.33/sq. ft//blk. The Ross plant was located 150 miles foom company should make for purchasing glass. Victoria had Dayton and lead time was one week. They had access to asked several suppliers to submit quotes, from which she an associated supplier in Illinois as an alternate souned had narrowed the alternatives to three of last year's sup- glass if they were unable to meet KII's demands. pliers and one former supplier, Jackson Glass Co. She summarized these quotes in her bid summary as shown Clear View Distributors. Clear View Distribus in Exhibit 2. was a small local glass distributor that had supplied KII SUPPLIERALTERNATIVESdeliveryoflowenergyglass.Theybasdalsobuiltselolforthreeyears.Theyhadprovidedconsistent,on-tink Ross Industries. Ross Industries was a glass man-_ units for KII, but there had been problems with some ufacturer that had provided KII with excellent service units. Both clear glass (made by Ross Industries) aed and good quality glass for 20 years. Their low energy low energy glass (made by West Bend Glass) were asal able on a mixed eight-block truck. Delivery was availats rither chat glase for the current year daily, if requested, and they were willing to stock inven- three to four times a week. They were willing to stock bory for KII. inventory for KII. Travers Glass Ltd. Travers Glass Ltd, was a glass dis- Jackson Glass Co. Jackson Glass Co. was a glass tributor about twice the size of Clear View Distributors. manufacturer that had been one of several suppliers to They had provided KII with service for 15 years and had KII in the past. They were very interested in doing busibeen an excellent backup service for Ross Industries. ness with KII again. Their glass quality was good and They offered clear glass (made by Jackson Glass Co.) they would supply 3mm clear glass at a delivered price at the lowest delivered price of $.3172/sq. ft./blk in of $.33/sq. ft./blk for a minimum order of six blocks. a straight or mixed truckload of at least 12 blocks with Jackson's quote for 4mm clear glass was $.44/sq. ft./blk. law energy glass (made by West Bend Glass). The quote Their low energy glass would require KII's testing lab's for 4mm clear glass was $.4389/sq. ft./blk. For low approval. The Jackson distribution center was located energy glass, their quote was $0.6734/sq. ft./blk for 3mm about 130 miles from Dayton and lead time was one and $0.9512/sq. ft./blk for 4mm glass. Clear glass made week. They were aligned with a Canadian supplier that by Ross Industries was also available at a higher price could provide an alternate source of glass if required. than the clear glass made by West Bend Glass. Their Now that she had gathered the necessary information, ditribution centre was located 135 miles from Dayton. Victoria needed to proceed with her analysis. She knew Lead time was two to three days and they could deliver that she would have to make her recommendation soon