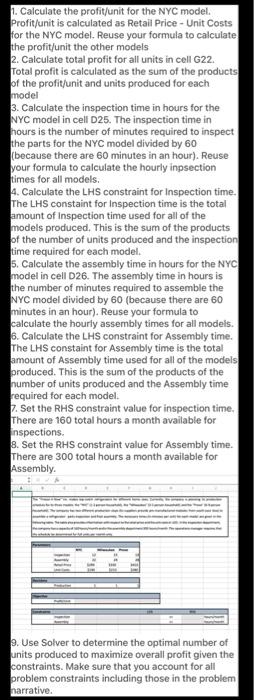

1. Calculate the profit/unit for the NYC model. Profit/unit is calculated as Retail Price - Unit Costs for the NYC model. Reuse your formula to calculate the profit/unit the other models 2. Calculate total profit for all units in cell G22. Total profit is calculated as the sum of the products of the profit/unit and units produced for each model 3. Calculate the inspection time in hours for the NYC model in cell D25. The inspection time in hours is the number of minutes required to inspect the parts for the NYC model divided by 60 (because there are 60 minutes in an hour). Reuse your formula to calculate the hourly inpsection times for all models. 4. Calculate the LHS constraint for Inspection time The LHS constant for inspection time is the total amount of Inspection time used for all of the models produced. This is the sum of the products of the number of units produced and the inspection time required for each model. 5. Calculate the assembly time in hours for the NYC model in cell D26. The assembly time in hours is the number of minutes required to assemble the NYC model divided by 60 (because there are 60 minutes in an hour). Reuse your formula to calculate the hourly assembly times for all models. 6. Calculate the LHS constraint for Assembly time. The LHS constant for Assembly time is the total amount of Assembly time used for all of the models produced. This is the sum of the products of the number of units produced and the Assembly time required for each model 7. Set the RHS constraint value for inspection time, There are 160 total hours a month available for Inspections. 8. Set the RHS constraint value for Assembly time. There are 300 total hours a month available for Assembly 3. Use Solver to determine the optimal number of units produced to maximize overall profit given the constraints. Make sure that you account for all problem constraints including those in the problem narrative. 1. Calculate the profit/unit for the NYC model. Profit/unit is calculated as Retail Price - Unit Costs for the NYC model. Reuse your formula to calculate the profit/unit the other models 2. Calculate total profit for all units in cell G22. Total profit is calculated as the sum of the products of the profit/unit and units produced for each model 3. Calculate the inspection time in hours for the NYC model in cell D25. The inspection time in hours is the number of minutes required to inspect the parts for the NYC model divided by 60 (because there are 60 minutes in an hour). Reuse your formula to calculate the hourly inpsection times for all models. 4. Calculate the LHS constraint for Inspection time The LHS constant for inspection time is the total amount of Inspection time used for all of the models produced. This is the sum of the products of the number of units produced and the inspection time required for each model. 5. Calculate the assembly time in hours for the NYC model in cell D26. The assembly time in hours is the number of minutes required to assemble the NYC model divided by 60 (because there are 60 minutes in an hour). Reuse your formula to calculate the hourly assembly times for all models. 6. Calculate the LHS constraint for Assembly time. The LHS constant for Assembly time is the total amount of Assembly time used for all of the models produced. This is the sum of the products of the number of units produced and the Assembly time required for each model 7. Set the RHS constraint value for inspection time, There are 160 total hours a month available for Inspections. 8. Set the RHS constraint value for Assembly time. There are 300 total hours a month available for Assembly 3. Use Solver to determine the optimal number of units produced to maximize overall profit given the constraints. Make sure that you account for all problem constraints including those in the problem narrative