Question

1. Calculate the unit product cost for Model B using the traditional costing system. 2. Calculate the unit product cost for Model B using the

1. Calculate the unit product cost for Model B using the traditional costing system.

2. Calculate the unit product cost for Model B using the ABC system.

3. Compare the unit product cost for Model B between these two costing systems. If the company continues to use its traditional costing system, what does that tell you about Model B?

4. If Smith Company continues to use its traditional costing system, what does that tell you about the other two devices? What must be true about them? (no calculations required)

5. Why are your answers in questions 1 and 2 different? Be specific.

6. What characteristics of Smith Company suggest that changing to an ABC system might benefit it? Which costing system do you recommend Smith Company use? Why?

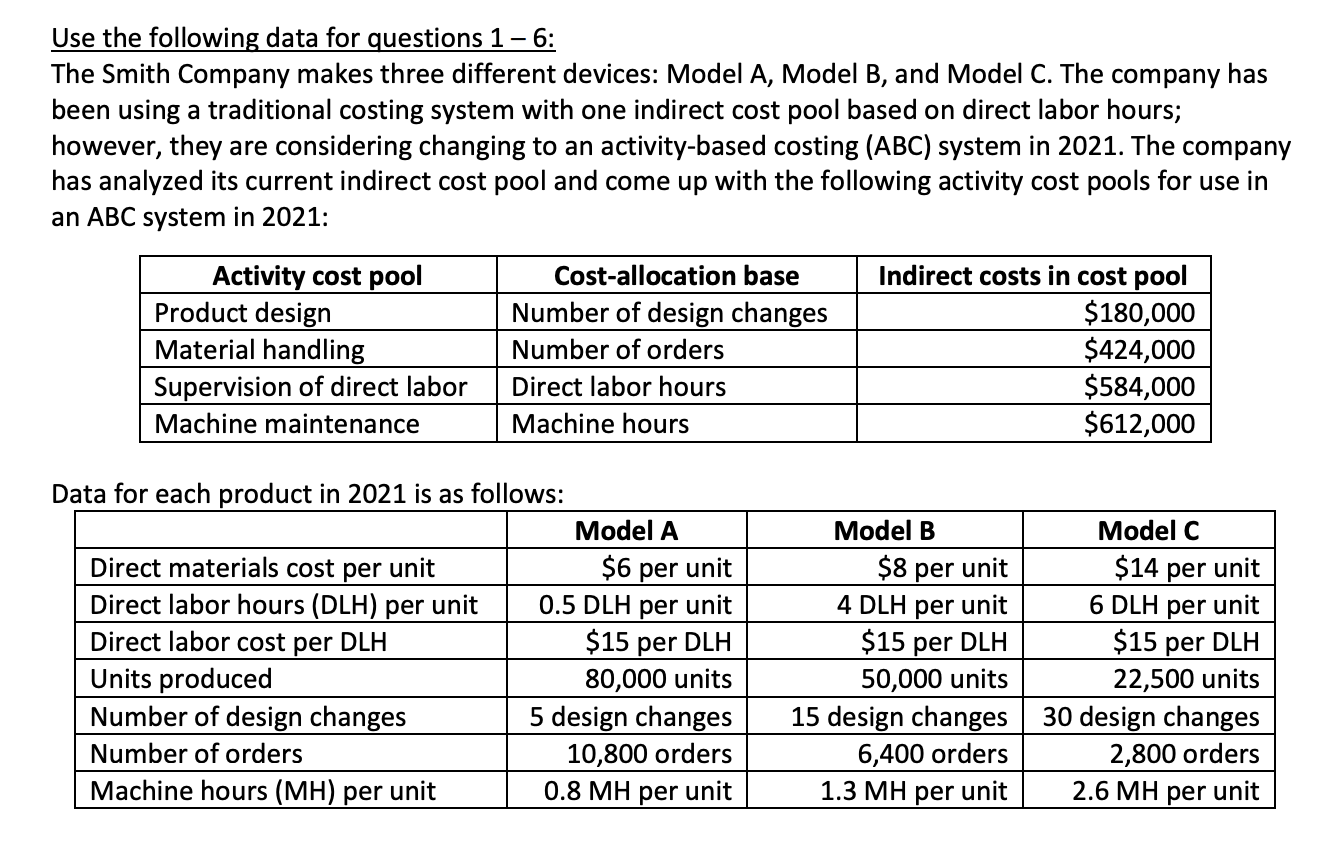

Use the following data for questions 1-6: The Smith Company makes three different devices: Model A, Model B, and Model C. The company has been using a traditional costing system with one indirect cost pool based on direct labor hours; however, they are considering changing to an activity-based costing (ABC) system in 2021. The company has analyzed its current indirect cost pool and come up with the following activity cost pools for use in an ABC system in 2021: Activity cost pool Product design Material handling Supervision of direct labor Machine maintenance Cost-allocation base Number of design changes Number of orders Direct labor hours Machine hours Indirect costs in cost pool $180,000 $424,000 $584,000 $612,000 Data for each product in 2021 is as follows: Model A Direct materials cost per unit $6 per unit Direct labor hours (DLH) per unit 0.5 DLH per unit Direct labor cost per DLH $15 per DLH Units produced 80,000 units Number of design changes 5 design changes Number of orders 10,800 orders Machine hours (MH) per unit 0.8 MH per unit Model B $8 per unit 4 DLH per unit $15 per DLH 50,000 units 15 design changes 6,400 orders 1.3 MH per unit Model C $14 per unit 6 DLH per unit $15 per DLH 22,500 units 30 design changes 2,800 orders 2.6 MH per unitStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started