Question: 1. Consider a sugar solution ( 5wt%) at 110C and 200kPa is fed to a double-effect evaporator. The first evaporator operates at 100kPa pressure and

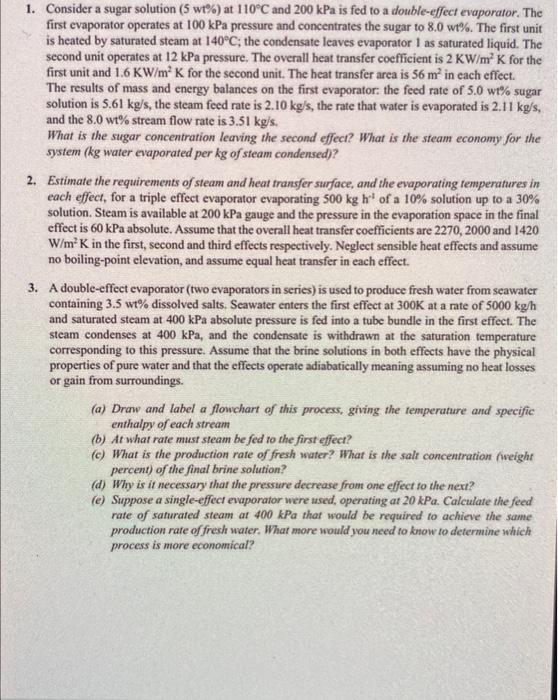

1. Consider a sugar solution ( 5wt%) at 110C and 200kPa is fed to a double-effect evaporator. The first evaporator operates at 100kPa pressure and concentrates the sugar to 8.0wt%. The first unit is heated by saturated steam at 140C; the condensate leaves evaporator 1 as saturated liquid. The second unit operates at 12kPa pressure. The overall heat transfer coefficient is 2KW/m2K for the first unit and 1.6KW/m2K for the second unit. The heat transfer area is 56m2 in each effect. The results of mass and energy balances on the first evaporator: the feed rate of 5.0wt% sugar solution is 5.61kg/s, the steam feed rate is 2.10kg/s, the rate that water is evaporated is 2.11kg/s, and the 8.0wt% stream flow rate is 3.51kg/s. What is the sugar concentration leaving the second effect? What is the steam economy for the system ( kg water evaporated per kg of steam condensed)? 2. Estimate the requirements of steam and heat transfer sufface, and the evaporating temperatures in each effect, for a triple effect evaporator evaporating 500kgh1 of a 10% solution up to a 30% solution. Steam is available at 200kPa gauge and the pressure in the evaporation space in the final effect is 60kPa absolute. Assume that the overall heat transfer coefficients are 2270,2000 and 1420 W/m2K in the first, second and third effects respectively. Neglect sensible heat effects and assume no boiling-point elevation, and assume equal heat transfer in each effect. 3. A double-effect evaporator (two evaporators in series) is used to produce fresh water from seawater containing 3.5wt% dissolved salts. Seawater enters the first effect at 300K at a rate of 5000kg/h and saturated steam at 400kPa absolute pressure is fed into a tube bundle in the first effect. The steam condenses at 400kPa, and the condensate is withdrawn at the saturation temperature corresponding to this pressure. Assume that the brine solutions in both effects have the physical properties of pure water and that the effects operate adiabatically meaning assuming no heat losses or gain from surroundings. (a) Draw and label a flowchart of this process, giving the temperature and specific enthalpy of each stream (b) At what rate must steam be fed to the first effect? (c) What is the production rate of fresh water? What is the salt concentration fiveight percent) of the final brine solution? (d) Why is it necessary that the pressure decrease from one effect to the next? (e) Suppose a single-effect evaporator were used, operating at 20kPa. Calculate the feed rate of sahurated steam at 400kPa that would be required to achieve the same production rate of fresh water. What more would you need to know to determine which process is more economical

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts