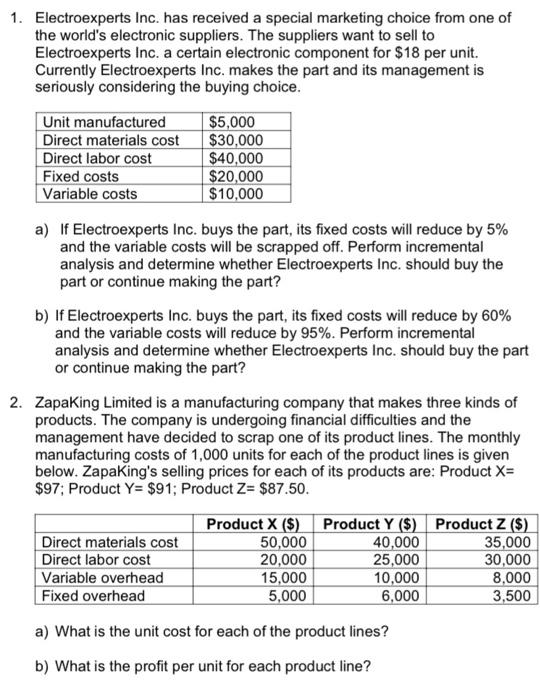

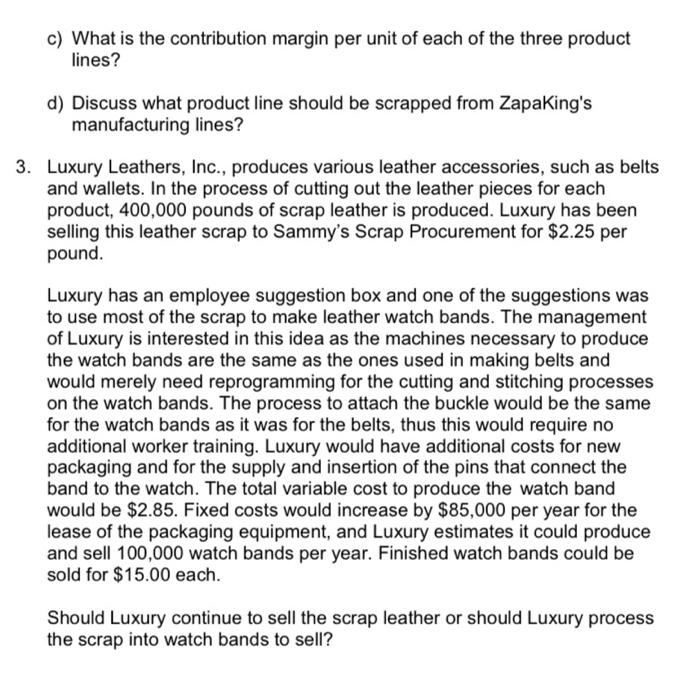

1. Electroexperts Inc. has received a special marketing choice from one of the world's electronic suppliers. The suppliers want to sell to Electroexperts Inc. a certain electronic component for $18 per unit. Currently Electroexperts Inc. makes the part and its management is seriously considering the buying choice. a) If Electroexperts Inc. buys the part, its fixed costs will reduce by 5% and the variable costs will be scrapped off. Perform incremental analysis and determine whether Electroexperts Inc. should buy the part or continue making the part? b) If Electroexperts Inc. buys the part, its fixed costs will reduce by 60% and the variable costs will reduce by 95%. Perform incremental analysis and determine whether Electroexperts Inc. should buy the part or continue making the part? 2. ZapaKing Limited is a manufacturing company that makes three kinds of products. The company is undergoing financial difficulties and the management have decided to scrap one of its product lines. The monthly manufacturing costs of 1,000 units for each of the product lines is given below. ZapaKing's selling prices for each of its products are: Product X= $97; Product Y=$91; Product Z=$87.50. a) What is the unit cost for each of the product lines? b) What is the profit per unit for each product line? c) What is the contribution margin per unit of each of the three product lines? d) Discuss what product line should be scrapped from ZapaKing's manufacturing lines? Luxury Leathers, Inc., produces various leather accessories, such as belts and wallets. In the process of cutting out the leather pieces for each product, 400,000 pounds of scrap leather is produced. Luxury has been selling this leather scrap to Sammy's Scrap Procurement for $2.25 per pound. Luxury has an employee suggestion box and one of the suggestions was to use most of the scrap to make leather watch bands. The management of Luxury is interested in this idea as the machines necessary to produce the watch bands are the same as the ones used in making belts and would merely need reprogramming for the cutting and stitching processes on the watch bands. The process to attach the buckle would be the same for the watch bands as it was for the belts, thus this would require no additional worker training. Luxury would have additional costs for new packaging and for the supply and insertion of the pins that connect the band to the watch. The total variable cost to produce the watch band would be $2.85. Fixed costs would increase by $85,000 per year for the lease of the packaging equipment, and Luxury estimates it could produce and sell 100,000 watch bands per year. Finished watch bands could be sold for $15.00 each. Should Luxury continue to sell the scrap leather or should Luxury process the scrap into watch bands to sell