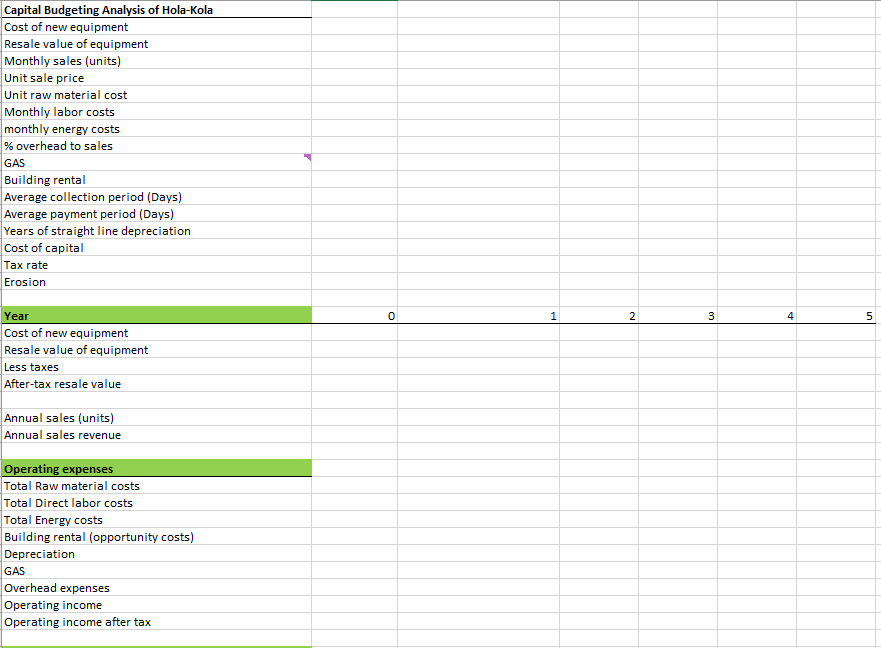

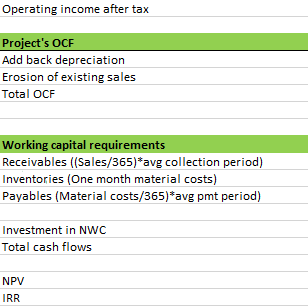

Question: 1. Evaluate the relevant cash flows for the project. Note: Working capital has three components: Receivables, Inventories, and Payables. Define working capital requirement as: Receivables

![as: Receivables [(Sales/365)* average collection period] + Inventories [One month material costs]](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2024/10/67027e715d1b7_68967027e7102dc4.jpg)

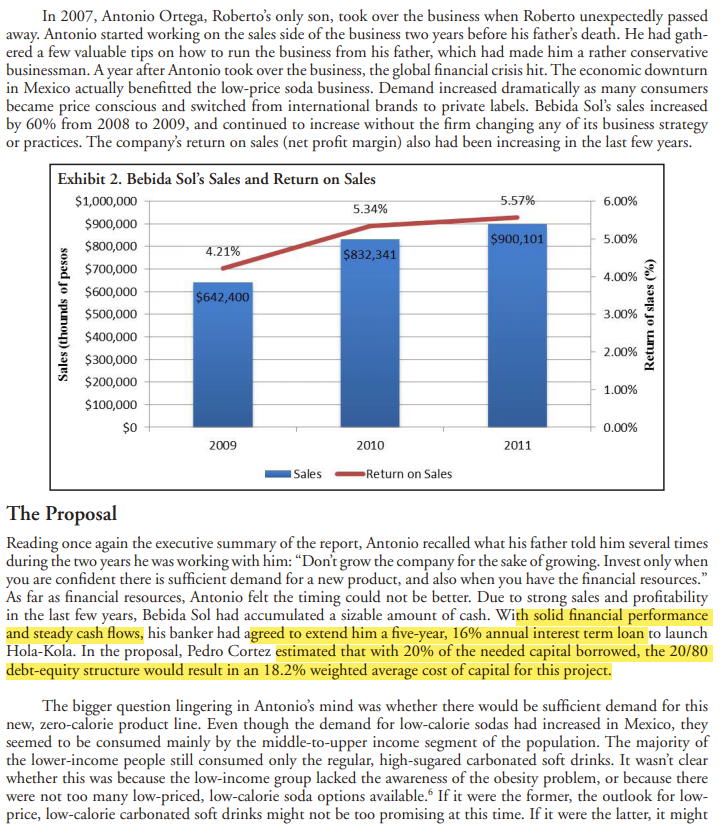

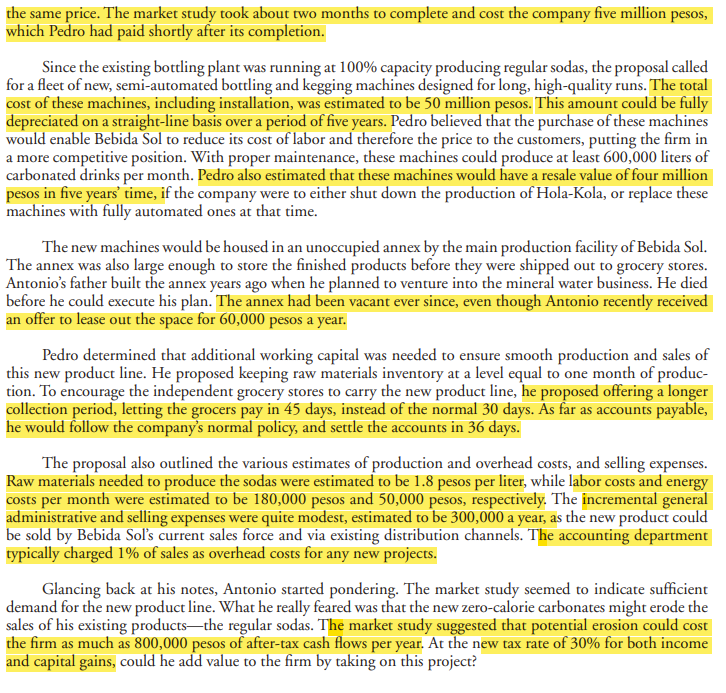

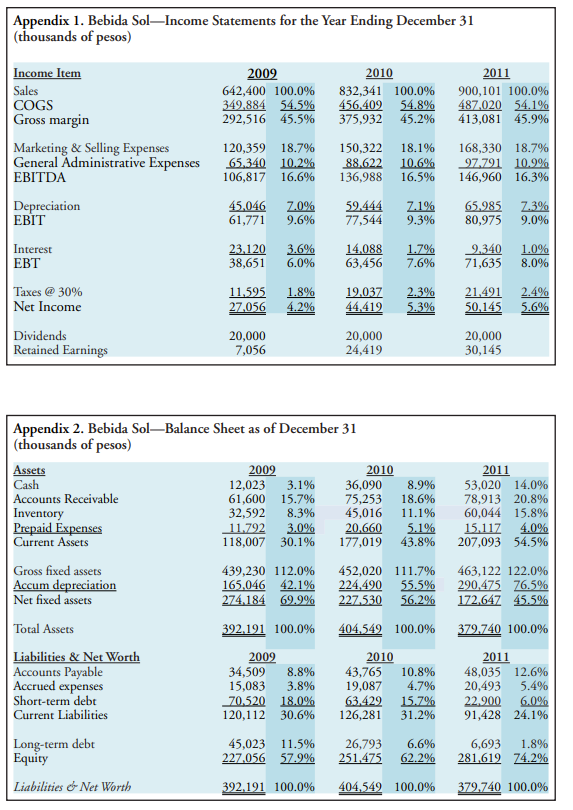

1. Evaluate the relevant cash flows for the project. Note: Working capital has three components: Receivables, Inventories, and Payables. Define working capital requirement as: Receivables [(Sales/365)* average collection period] + Inventories [One month material costs] - Payables [(Material costs/365)*average payment period) 2. Based on your projections of cash flows, compute a net present value (NPV) and internal rate of return (IRR). 3. In Excel file, type your response to the following: Based on your evaluation of business conditions and cash flow analysis, discuss the key variables that you think are critical to the value of the project. Using Data Table in Excel, conduct sensitivity analyses and examine the sensitivity of NPV to the key variables that you have identified. Discuss your results of sensitivity analysis. 4. Using the Scenario Manager tool in Excel, conduct a scenario analysis based on the following two conditions in addition to the base case. a) Scenario 1: the consultants advised that the energy costs, the labor costs, and the material costs are likely to rise by 5% a year, starting in Year 2. Assume that the company cannot pass the extra cost through. b) Scenario 2: the consultants advised that the energy costs, the labor costs, and the material costs are likely to rise by 5% a year, starting in Year 2. Assume that the company can pass the extra cost through by increasing the price per unit by 5%. However, this would lead to a 2% drop in volume. What do you observe comparing these two scenarios to the base case? In 2007, Antonio Ortega, Roberto's only son, took over the business when Roberto unexpectedly passed away. Antonio started working on the sales side of the business two years before his father's death. He had gath- ered a few valuable tips on how to run the business from his father, which had made him a rather conservative businessman. A year after Antonio took over the business, the global financial crisis hit. The economic downturn in Mexico actually benefitted the low-price soda business. Demand increased dramatically as many consumers became price conscious and switched from international brands to private labels. Bebida Sol's sales increased by 60% from 2008 to 2009, and continued to increase without the firm changing any of its business strategy or practices. The company's return on sales (net profit margin) also had been increasing in the last few years. Exhibit 2. Bebida Sol's Sales and Return on Sales $1,000,000 5.57% 6.00% 5.34% $900,000 $800,000 $900,101 5.00% 4.21% $832,341 $700,000 $600,000 $642,400 $500,000 3.00% $400,000 $300,000 2.00% $200,000 1.00% $100,000 $0 0.00% 2009 4.00% Sales (thounds of pesos Return of slaes (%) 2010 2011 Sales Return on Sales The Proposal Reading once again the executive summary of the report, Antonio recalled what his father told him several times during the two years he was working with him: Don't grow the company for the sake of growing. Invest only when you are confident there is sufficient demand for a new product, and also when you have the financial resources. As far as financial resources, Antonio felt the timing could not be better. Due to strong sales and profitability in the last few years, Bebida Sol had accumulated a sizable amount of cash. With solid financial performance and steady cash flows, his banker had agreed to extend him a five-year, 16% annual interest term loan to launch Hola-Kola. In the proposal, Pedro Cortez estimated that with 20% of the needed capital borrowed, the 20/80 debt-equity structure would result in an 18.2% weighted average cost of capital for this project. The bigger question lingering in Antonio's mind was whether there would be sufficient demand for this new, zero-calorie product line. Even though the demand for low-calorie sodas had increased in Mexico, they seemed to be consumed mainly by the middle-to-upper income segment of the population. The majority of the lower-income people still consumed only the regular, high-sugared carbonated soft drinks. It wasn't clear whether this was because the low-income group lacked the awareness of the obesity problem, or because there were not too many low-priced, low-calorie soda options available. If it were the former, the outlook for low- price, low-calorie carbonated soft drinks might not be too promising at this time. If it were the latter, it might price, low-calorie carbonated soft drinks might not be too promising at this time. If it were the latter, it might be the perfect timing for Bebida Sol to introduce Hola-Kola. Pedro hired a consultant to do a market study right after Antonio discussed the idea of Hola-Kola with him. The consultant estimated that the company could sell a total of 600,000 liters of these zero-calorie carbonates a month, at a projected price of five pesos a liter. This volume of sales was expected for a period of five years at the same price. The market study took about two months to complete and cost the company five million pesos, which Pedro had paid shortly after its completion. Since the existing bottling plant was running at 100% capacity producing regular sodas, the proposal called for a fleet of new, semi-automated bottling and kegging machines designed for long, high-quality runs. The total cost of these machines, including installation, was estimated to be 50 million pesos. This amount could be fully depreciated on a straight-line basis over a period of five years. Pedro believed that the purchase of these machines would enable Bebida Sol to reduce its cost of labor and therefore the price to the customers, putting the firm in a more competitive position. With proper maintenance, these machines could produce at least 600,000 liters of carbonated drinks per month. Pedro also estimated that these machines would have a resale value of four million pesos in five years' time, if the company were to either shut down the production of Hola-Kola, or replace these machines with fully automated ones at that time. The new machines would be housed in an unoccupied annex by the main production facility of Bebida Sol. The annex was also large enough to store the finished products before they were shipped out to grocery stores. Antonio's father built the annex years ago when he planned to venture into the mineral water business. He died before he could execute his plan. The annex had been vacant ever since, even though Antonio recently received an offer to lease out the space for 60,000 pesos a year. Pedro determined that additional working capital was needed to ensure smooth production and sales of this new product line. He proposed keeping raw materials inventory at a level equal to one month of produc- tion. To encourage the independent grocery stores to carry the new product line, he proposed offering a longer collection period, letting the grocers pay in 45 days, instead of the normal 30 days. As far as accounts payable, he would follow the company's normal policy, and settle the accounts in 36 days. The proposal also outlined the various estimates of production and overhead costs, and selling expenses. Raw materials needed to produce the sodas were estimated to be 1.8 pesos per liter, while labor costs and energy costs per month were estimated to be 180,000 pesos and 50,000 pesos, respectively. The incremental general administrative and selling expenses were quite modest, estimated to be 300,000 a year, as the new product could be sold by Bebida Sol's current sales force and via existing distribution channels. The accounting department typically charged 1% of sales as overhead costs for any new projects. Glancing back at his notes, Antonio started pondering. The market study seemed to indicate sufficient demand for the new product line. What he really feared was that the new zero-calorie carbonates might erode the sales of his existing productsthe regular sodas. The market study suggested that potential erosion could cost the firm as much as 800,000 pesos of after-tax cash flows per year. At the new tax rate of 30% for both income and capital gains, could he add value to the firm by taking on this project? Appendix 1. Bebida SolIncome Statements for the Year Ending December 31 (thousands of pesos) Income Item Sales COGS Gross margin Marketing & Selling Expenses General Administrative Expenses EBITDA 2009 642,400 100.0% 349,884 54.5% 292,516 45.5% 2010 832,341 100.0% 456,409 54.8% 375,932 45.2% 2011 900,101 100.0% 487,020 54.1% 413,081 45.9% 120,359 18.7% 65.340 10.29% 106,817 16.6% 150,322 88.622 136,988 18.1% 10.6% 16.5% 168,330 18.7% 97.791 10.9% 146,960 16.3% Depreciation EBIT 45,046 61,771 7.0% 9.6% 59.444 77,544 7.1% 9.3% 65.985 80,975 7.3% 9.0% Interest 23,120 38,651 3.6% 6.0% 14.088 63,456 1.7% 7.6% 9.340 71,635 1.0% 8.0% Taxes @ 30% Net Income 11.595 27,056 1.8% 4.29 19.037 44.419 2.3% 5.3% 21,491 50,145 2.4% 5.6% Dividends Retained Earnings 20,000 7,056 20,000 24,419 20,000 30,145 Appendix 2. Bebida Sol-Balance Sheet as of December 31 (thousands of pesos) Assets 2009 2010 Cash 12,023 3.1% 36,090 8.9% Accounts Receivable 61,600 15.7% 75,253 18.6% Inventory 32,592 8.3% 45,016 11.1% Prepaid Expenses 11.792 3.0% 20,660 5.1% Current Assets 118,007 30.1% 177,019 43.8% 2011 53,020 14.0% 78,913 20.8% 60,044 15.8% 15.117 4.0% 207,093 54.5% 439,230 112.0% 165,046 42.1% 274,184 69.9% 452,020 111.7% 224,490 55.5% 227.530 56.2% 463,122 122.0% 290,475 76.5% 172,647 45.5% 392.191 100.0% 404,549 100.0% 379.740 100.0% Gross fixed assets Accum depreciation Net fixed assets Total Assets Liabilities & Net Worth Accounts Payable Accrued expenses Short-term debt Current Liabilities 2009 34,509 8.8% 15,083 3.8% 70,520 18.0% 120,112 30.6% 2010 43,765 10.8% 19,087 4.7% 63.429 15.7% 126,281 31.2% 2011 48,035 12.6% 20,493 5.4% 22.000 6.0% 91,428 24.1% Long-term debt Equity 45,023 11.5% 227,056 57.9% 26,793 251,475 6.6% 62.2% 6,693 1.8% 281,619 74.2% Liabilities & Net Worth 392.191 100.0% 404,549 100.0% 379.740 100.0% Capital Budgeting Analysis of Hola-Kola Cost of new equipment Resale value of equipment Monthly sales (units) Unit sale price Unit raw material cost Monthly labor costs monthly energy costs % overhead to sales GAS Building rental Average collection period (Days) Average payment period (Days) Years of straight line depreciation Cost of capital Tax rate Erosion o 1 2 3 4 5 Year Cost of new equipment Resale value of equipment Less taxes After-tax resale value Annual sales (units) Annual sales revenue Operating expenses Total Raw material costs Total Direct labor costs Total Energy costs Building rental (opportunity costs) Depreciation GAS Overhead expenses Operating income Operating income after tax Operating income after tax Project's OCF Add back depreciation Erosion of existing sales Total OCF Working capital requirements Receivables (Sales/365)*avg collection period) Inventories (One month material costs) Payables (Material costs/365)*avg prt period) Investment in NWC Total cash flows NPV IRR 1. Evaluate the relevant cash flows for the project. Note: Working capital has three components: Receivables, Inventories, and Payables. Define working capital requirement as: Receivables [(Sales/365)* average collection period] + Inventories [One month material costs] - Payables [(Material costs/365)*average payment period) 2. Based on your projections of cash flows, compute a net present value (NPV) and internal rate of return (IRR). 3. In Excel file, type your response to the following: Based on your evaluation of business conditions and cash flow analysis, discuss the key variables that you think are critical to the value of the project. Using Data Table in Excel, conduct sensitivity analyses and examine the sensitivity of NPV to the key variables that you have identified. Discuss your results of sensitivity analysis. 4. Using the Scenario Manager tool in Excel, conduct a scenario analysis based on the following two conditions in addition to the base case. a) Scenario 1: the consultants advised that the energy costs, the labor costs, and the material costs are likely to rise by 5% a year, starting in Year 2. Assume that the company cannot pass the extra cost through. b) Scenario 2: the consultants advised that the energy costs, the labor costs, and the material costs are likely to rise by 5% a year, starting in Year 2. Assume that the company can pass the extra cost through by increasing the price per unit by 5%. However, this would lead to a 2% drop in volume. What do you observe comparing these two scenarios to the base case? In 2007, Antonio Ortega, Roberto's only son, took over the business when Roberto unexpectedly passed away. Antonio started working on the sales side of the business two years before his father's death. He had gath- ered a few valuable tips on how to run the business from his father, which had made him a rather conservative businessman. A year after Antonio took over the business, the global financial crisis hit. The economic downturn in Mexico actually benefitted the low-price soda business. Demand increased dramatically as many consumers became price conscious and switched from international brands to private labels. Bebida Sol's sales increased by 60% from 2008 to 2009, and continued to increase without the firm changing any of its business strategy or practices. The company's return on sales (net profit margin) also had been increasing in the last few years. Exhibit 2. Bebida Sol's Sales and Return on Sales $1,000,000 5.57% 6.00% 5.34% $900,000 $800,000 $900,101 5.00% 4.21% $832,341 $700,000 $600,000 $642,400 $500,000 3.00% $400,000 $300,000 2.00% $200,000 1.00% $100,000 $0 0.00% 2009 4.00% Sales (thounds of pesos Return of slaes (%) 2010 2011 Sales Return on Sales The Proposal Reading once again the executive summary of the report, Antonio recalled what his father told him several times during the two years he was working with him: Don't grow the company for the sake of growing. Invest only when you are confident there is sufficient demand for a new product, and also when you have the financial resources. As far as financial resources, Antonio felt the timing could not be better. Due to strong sales and profitability in the last few years, Bebida Sol had accumulated a sizable amount of cash. With solid financial performance and steady cash flows, his banker had agreed to extend him a five-year, 16% annual interest term loan to launch Hola-Kola. In the proposal, Pedro Cortez estimated that with 20% of the needed capital borrowed, the 20/80 debt-equity structure would result in an 18.2% weighted average cost of capital for this project. The bigger question lingering in Antonio's mind was whether there would be sufficient demand for this new, zero-calorie product line. Even though the demand for low-calorie sodas had increased in Mexico, they seemed to be consumed mainly by the middle-to-upper income segment of the population. The majority of the lower-income people still consumed only the regular, high-sugared carbonated soft drinks. It wasn't clear whether this was because the low-income group lacked the awareness of the obesity problem, or because there were not too many low-priced, low-calorie soda options available. If it were the former, the outlook for low- price, low-calorie carbonated soft drinks might not be too promising at this time. If it were the latter, it might price, low-calorie carbonated soft drinks might not be too promising at this time. If it were the latter, it might be the perfect timing for Bebida Sol to introduce Hola-Kola. Pedro hired a consultant to do a market study right after Antonio discussed the idea of Hola-Kola with him. The consultant estimated that the company could sell a total of 600,000 liters of these zero-calorie carbonates a month, at a projected price of five pesos a liter. This volume of sales was expected for a period of five years at the same price. The market study took about two months to complete and cost the company five million pesos, which Pedro had paid shortly after its completion. Since the existing bottling plant was running at 100% capacity producing regular sodas, the proposal called for a fleet of new, semi-automated bottling and kegging machines designed for long, high-quality runs. The total cost of these machines, including installation, was estimated to be 50 million pesos. This amount could be fully depreciated on a straight-line basis over a period of five years. Pedro believed that the purchase of these machines would enable Bebida Sol to reduce its cost of labor and therefore the price to the customers, putting the firm in a more competitive position. With proper maintenance, these machines could produce at least 600,000 liters of carbonated drinks per month. Pedro also estimated that these machines would have a resale value of four million pesos in five years' time, if the company were to either shut down the production of Hola-Kola, or replace these machines with fully automated ones at that time. The new machines would be housed in an unoccupied annex by the main production facility of Bebida Sol. The annex was also large enough to store the finished products before they were shipped out to grocery stores. Antonio's father built the annex years ago when he planned to venture into the mineral water business. He died before he could execute his plan. The annex had been vacant ever since, even though Antonio recently received an offer to lease out the space for 60,000 pesos a year. Pedro determined that additional working capital was needed to ensure smooth production and sales of this new product line. He proposed keeping raw materials inventory at a level equal to one month of produc- tion. To encourage the independent grocery stores to carry the new product line, he proposed offering a longer collection period, letting the grocers pay in 45 days, instead of the normal 30 days. As far as accounts payable, he would follow the company's normal policy, and settle the accounts in 36 days. The proposal also outlined the various estimates of production and overhead costs, and selling expenses. Raw materials needed to produce the sodas were estimated to be 1.8 pesos per liter, while labor costs and energy costs per month were estimated to be 180,000 pesos and 50,000 pesos, respectively. The incremental general administrative and selling expenses were quite modest, estimated to be 300,000 a year, as the new product could be sold by Bebida Sol's current sales force and via existing distribution channels. The accounting department typically charged 1% of sales as overhead costs for any new projects. Glancing back at his notes, Antonio started pondering. The market study seemed to indicate sufficient demand for the new product line. What he really feared was that the new zero-calorie carbonates might erode the sales of his existing productsthe regular sodas. The market study suggested that potential erosion could cost the firm as much as 800,000 pesos of after-tax cash flows per year. At the new tax rate of 30% for both income and capital gains, could he add value to the firm by taking on this project? Appendix 1. Bebida SolIncome Statements for the Year Ending December 31 (thousands of pesos) Income Item Sales COGS Gross margin Marketing & Selling Expenses General Administrative Expenses EBITDA 2009 642,400 100.0% 349,884 54.5% 292,516 45.5% 2010 832,341 100.0% 456,409 54.8% 375,932 45.2% 2011 900,101 100.0% 487,020 54.1% 413,081 45.9% 120,359 18.7% 65.340 10.29% 106,817 16.6% 150,322 88.622 136,988 18.1% 10.6% 16.5% 168,330 18.7% 97.791 10.9% 146,960 16.3% Depreciation EBIT 45,046 61,771 7.0% 9.6% 59.444 77,544 7.1% 9.3% 65.985 80,975 7.3% 9.0% Interest 23,120 38,651 3.6% 6.0% 14.088 63,456 1.7% 7.6% 9.340 71,635 1.0% 8.0% Taxes @ 30% Net Income 11.595 27,056 1.8% 4.29 19.037 44.419 2.3% 5.3% 21,491 50,145 2.4% 5.6% Dividends Retained Earnings 20,000 7,056 20,000 24,419 20,000 30,145 Appendix 2. Bebida Sol-Balance Sheet as of December 31 (thousands of pesos) Assets 2009 2010 Cash 12,023 3.1% 36,090 8.9% Accounts Receivable 61,600 15.7% 75,253 18.6% Inventory 32,592 8.3% 45,016 11.1% Prepaid Expenses 11.792 3.0% 20,660 5.1% Current Assets 118,007 30.1% 177,019 43.8% 2011 53,020 14.0% 78,913 20.8% 60,044 15.8% 15.117 4.0% 207,093 54.5% 439,230 112.0% 165,046 42.1% 274,184 69.9% 452,020 111.7% 224,490 55.5% 227.530 56.2% 463,122 122.0% 290,475 76.5% 172,647 45.5% 392.191 100.0% 404,549 100.0% 379.740 100.0% Gross fixed assets Accum depreciation Net fixed assets Total Assets Liabilities & Net Worth Accounts Payable Accrued expenses Short-term debt Current Liabilities 2009 34,509 8.8% 15,083 3.8% 70,520 18.0% 120,112 30.6% 2010 43,765 10.8% 19,087 4.7% 63.429 15.7% 126,281 31.2% 2011 48,035 12.6% 20,493 5.4% 22.000 6.0% 91,428 24.1% Long-term debt Equity 45,023 11.5% 227,056 57.9% 26,793 251,475 6.6% 62.2% 6,693 1.8% 281,619 74.2% Liabilities & Net Worth 392.191 100.0% 404,549 100.0% 379.740 100.0% Capital Budgeting Analysis of Hola-Kola Cost of new equipment Resale value of equipment Monthly sales (units) Unit sale price Unit raw material cost Monthly labor costs monthly energy costs % overhead to sales GAS Building rental Average collection period (Days) Average payment period (Days) Years of straight line depreciation Cost of capital Tax rate Erosion o 1 2 3 4 5 Year Cost of new equipment Resale value of equipment Less taxes After-tax resale value Annual sales (units) Annual sales revenue Operating expenses Total Raw material costs Total Direct labor costs Total Energy costs Building rental (opportunity costs) Depreciation GAS Overhead expenses Operating income Operating income after tax Operating income after tax Project's OCF Add back depreciation Erosion of existing sales Total OCF Working capital requirements Receivables (Sales/365)*avg collection period) Inventories (One month material costs) Payables (Material costs/365)*avg prt period) Investment in NWC Total cash flows NPV IRR

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts