Answered step by step

Verified Expert Solution

Question

1 Approved Answer

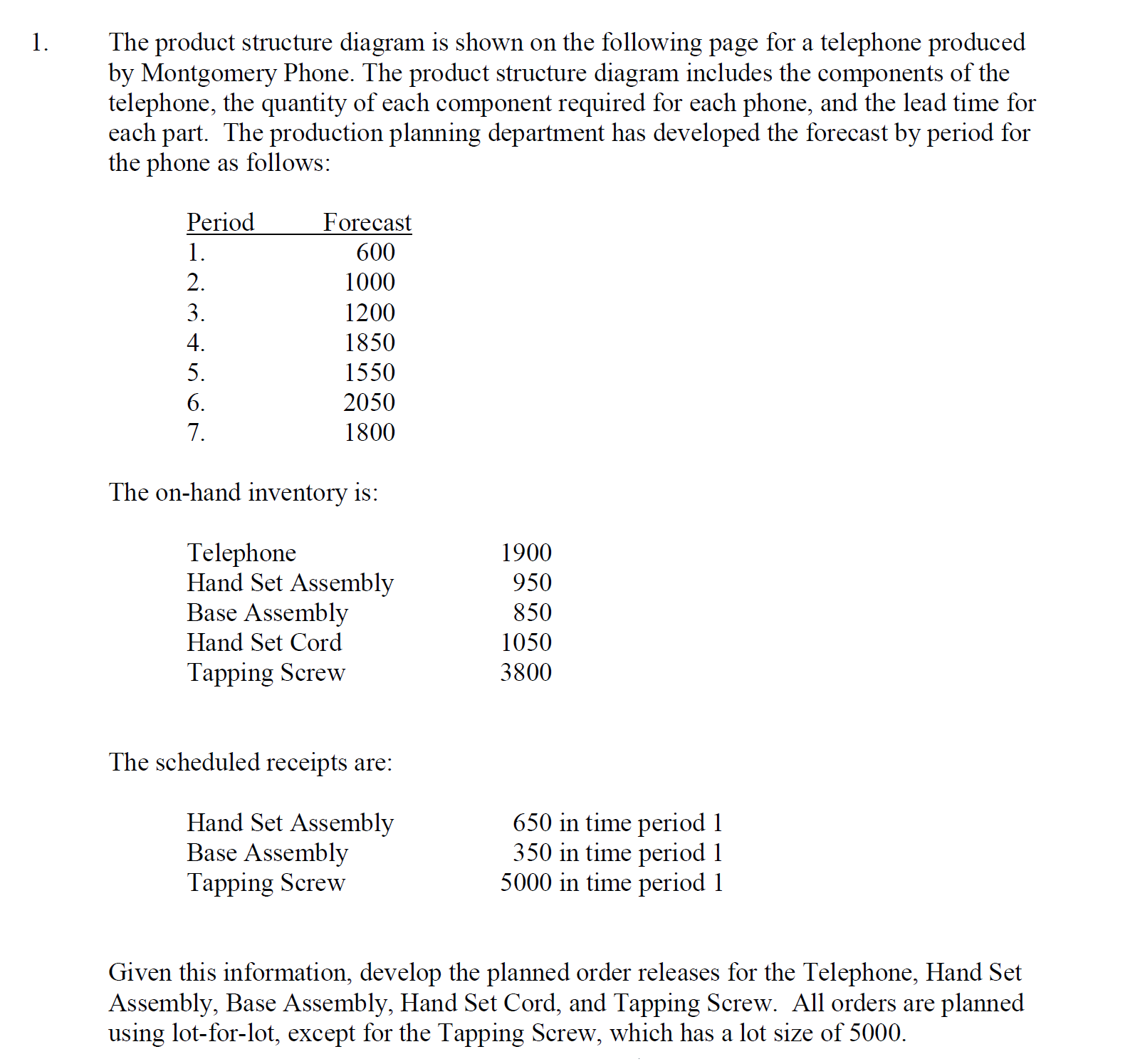

1. The product structure diagram is shown on the following page for a telephone produced by Montgomery Phone. The product structure diagram includes the

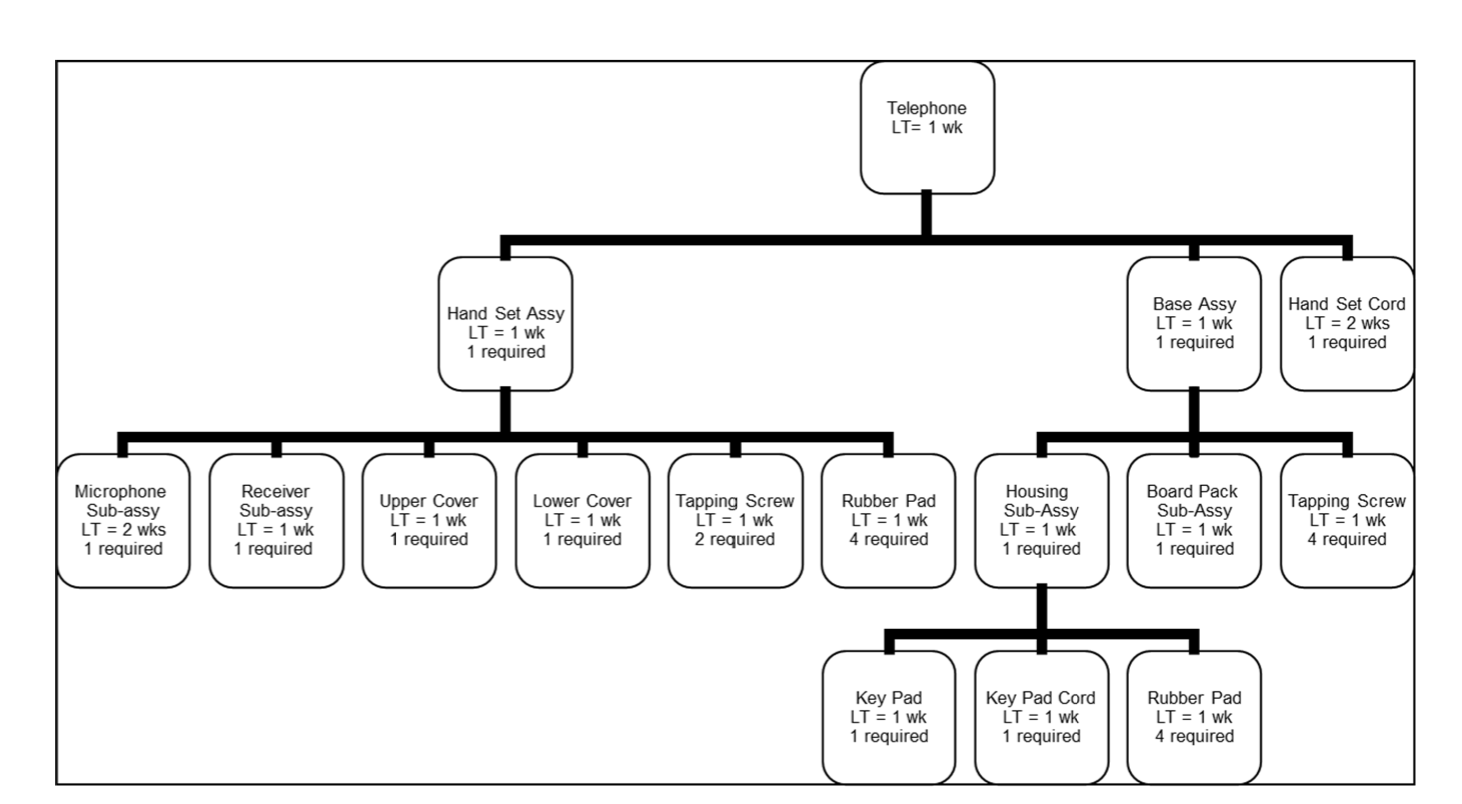

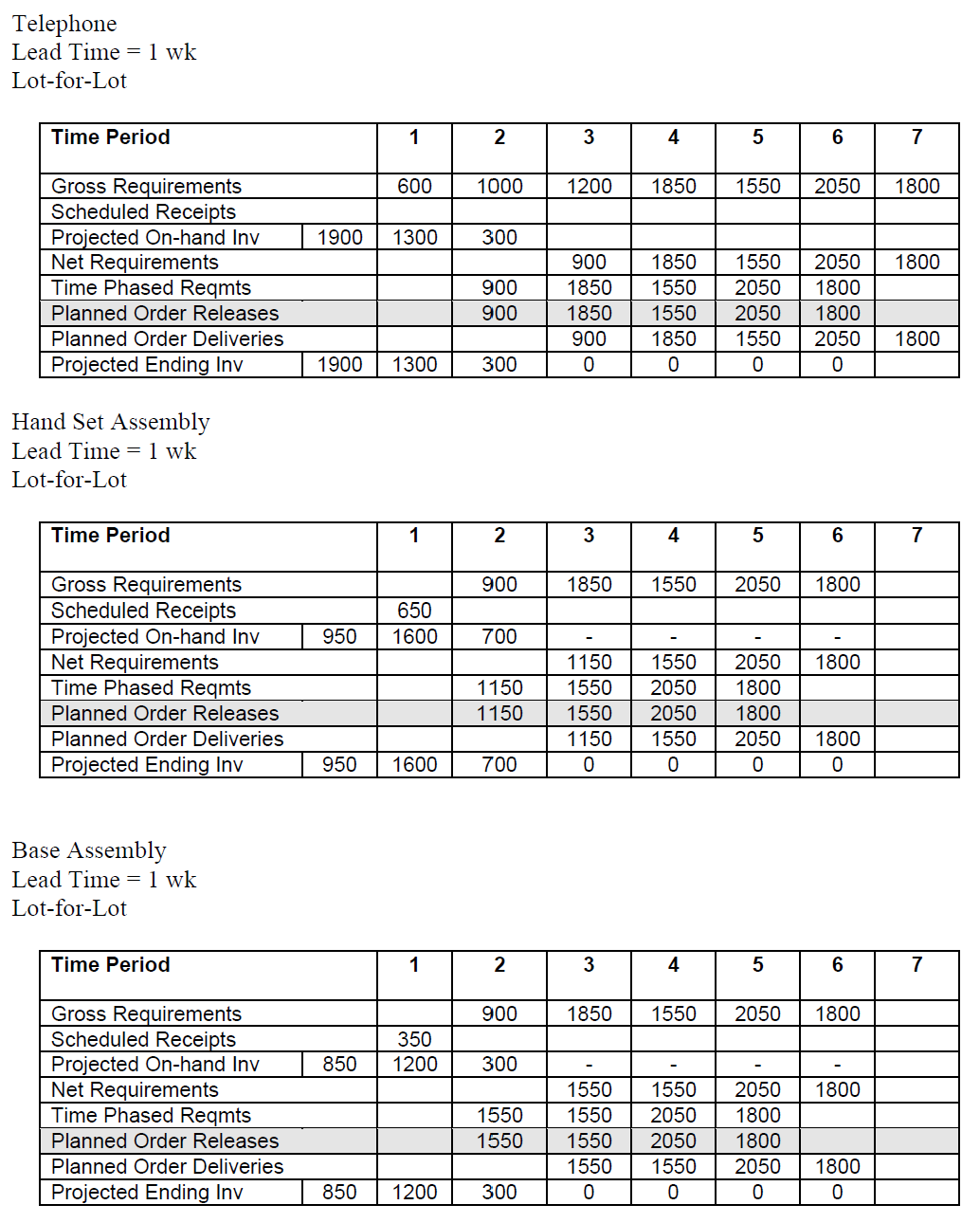

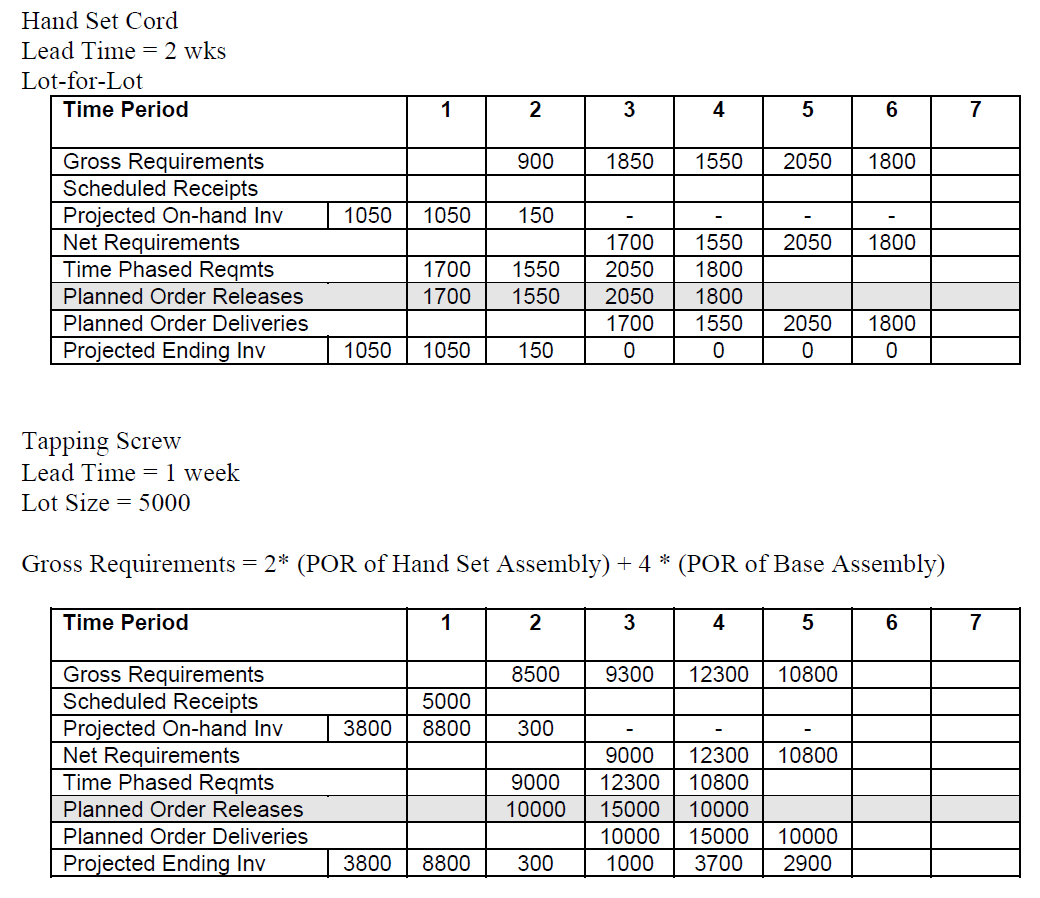

1. The product structure diagram is shown on the following page for a telephone produced by Montgomery Phone. The product structure diagram includes the components of the telephone, the quantity of each component required for each phone, and the lead time for each part. The production planning department has developed the forecast by period for the phone as follows: Period Forecast 1. 600 2. 1000 3. 1200 4. 1850 5. 1550 6. 2050 7. 1800 The on-hand inventory is: Telephone 1900 Hand Set Assembly 950 Base Assembly 850 Hand Set Cord 1050 3800 Tapping Screw The scheduled receipts are: Hand Set Assembly 650 in time period 1 Base Assembly 350 in time period 1 Tapping Screw 5000 in time period 1 Given this information, develop the planned order releases for the Telephone, Hand Set Assembly, Base Assembly, Hand Set Cord, and Tapping Screw. All orders are planned using lot-for-lot, except for the Tapping Screw, which has a lot size of 5000. Hand Set Assy LT = 1 wk 1 required Microphone Sub-assy LT = 2 wks 1 required Receiver Sub-assy LT = 1 wk 1 required Upper Cover LT = 1 wk 1 required Telephone LT= 1 wk Base Assy LT = 1 wk 1 required Hand Set Cord LT = 2 wks 1 required Housing Sub-Assy LT = 1 wk Board Pack Sub-Assy LT = 1 wk 1 required Tapping Screw LT = 1 wk 4 required Lower Cover LT = 1 wk 1 required Tapping Screw LT = 1 wk 2 required Rubber Pad LT = 1 wk 4 required 1 required Key Pad LT = 1 wk Key Pad Cord LT = 1 wk 1 required 1 required Rubber Pad LT = 1 wk 4 required Telephone Lead Time = 1 wk Lot-for-Lot Time Period 1 2 3 4 5 6 7 Gross Requirements Scheduled Receipts 600 1000 1200 1850 1550 2050 1800 Projected On-hand Inv 1900 1300 300 Net Requirements 900 1850 Time Phased Reqmts 900 1850 1550 2050 1550 2050 1800 1800 Planned Order Releases 900 1850 1550 2050 1800 Planned Order Deliveries 900 1850 1550 2050 1800 Projected Ending Inv 1900 1300 300 0 0 0 0 Hand Set Assembly Lead Time = 1 wk Lot-for-Lot Time Period Gross Requirements 1 2 3 4 5 6 7 900 1850 1550 2050 1800 Scheduled Receipts Projected On-hand Inv 650 950 1600 700 Net Requirements 1150 1550 2050 1800 Time Phased Reqmts 1150 1550 2050 1800 Planned Order Releases 1150 1550 2050 1800 Planned Order Deliveries 1150 1550 2050 1800 Projected Ending Inv 950 1600 700 0 0 0 0 Base Assembly Lead Time = 1 wk Lot-for-Lot Time Period 1 2 3 4 5 6 7 Gross Requirements 900 1850 1550 2050 1800 Scheduled Receipts 350 Projected On-hand Inv 850 1200 300 - Net Requirements Time Phased Reqmts 1550 1550 2050 1800 1550 1550 2050 1800 Planned Order Releases 1550 1550 2050 1800 Planned Order Deliveries 1550 1550 2050 1800 Projected Ending Inv 850 1200 300 0 0 0 0 Hand Set Cord Lead Time 2 wks Lot-for-Lot Time Period 1 2 3 4 5 6 7 Gross Requirements 900 1850 1550 2050 1800 Scheduled Receipts Projected On-hand Inv 1050 1050 150 Net Requirements 1700 1550 2050 1800 Time Phased Reqmts 1700 1550 2050 1800 Planned Order Releases 1700 1550 2050 1800 Planned Order Deliveries 1700 1550 2050 1800 Projected Ending Inv 1050 1050 150 0 0 0 0 Tapping Screw Lead Time = 1 week Lot Size 5000 Gross Requirements: 2* (POR of Hand Set Assembly) + 4 * (POR of Base Assembly) Time Period 1 2 3 4 5 6 7 Gross Requirements 8500 9300 12300 10800 Scheduled Receipts 5000 Projected On-hand Inv 3800 8800 300 Net Requirements Time Phased Reqmts 9000 9000 12300 10800 12300 10800 Planned Order Releases 10000 15000 10000 Planned Order Deliveries 10000 15000 10000 Projected Ending Inv 3800 8800 300 1000 3700 2900

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started