1). Using the given information below, what is the manufacturing overhead?

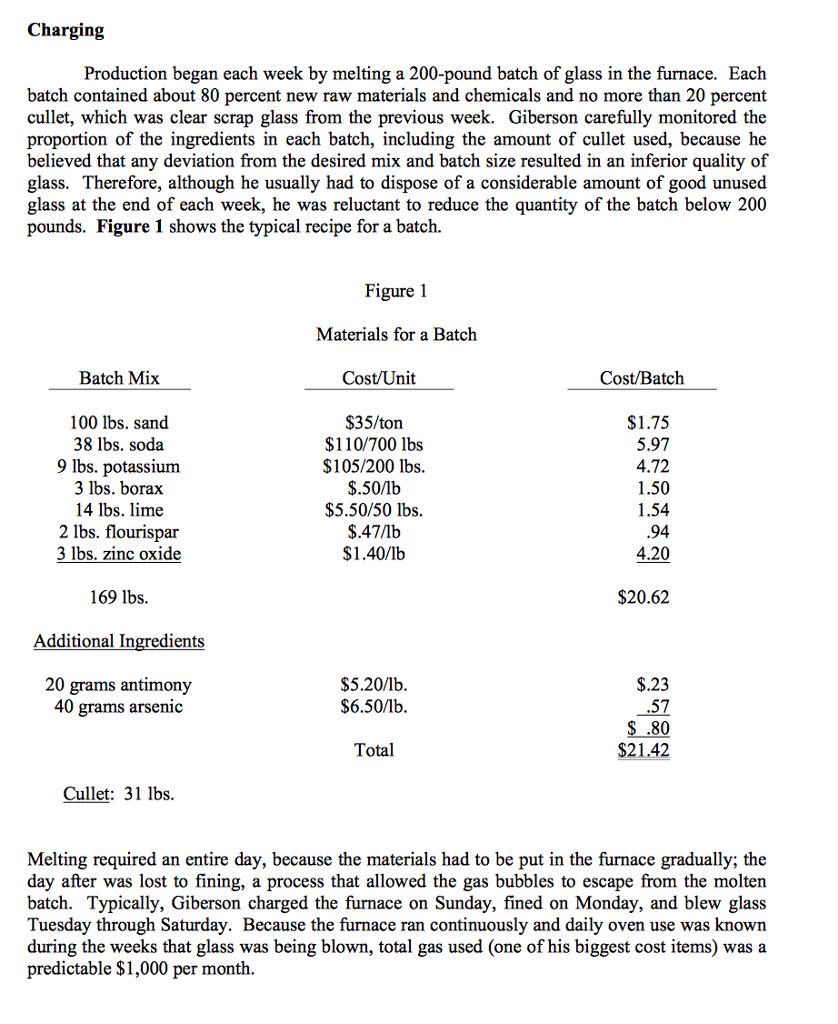

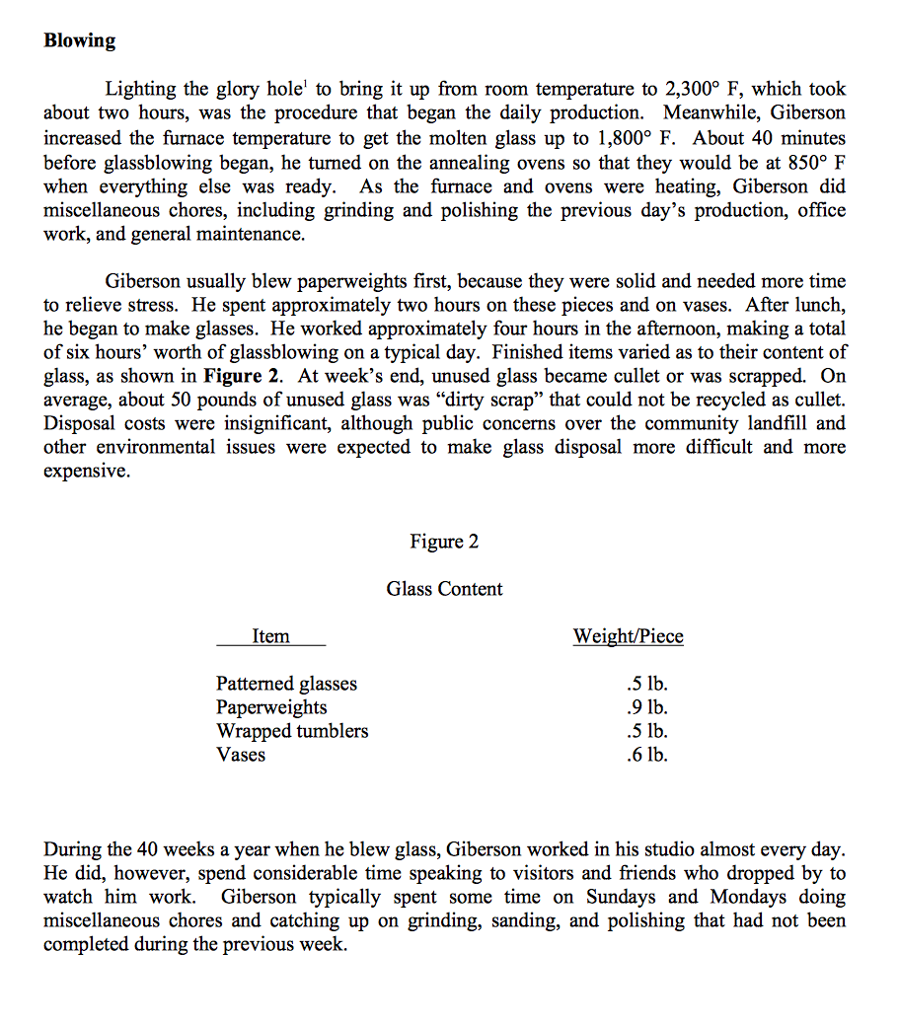

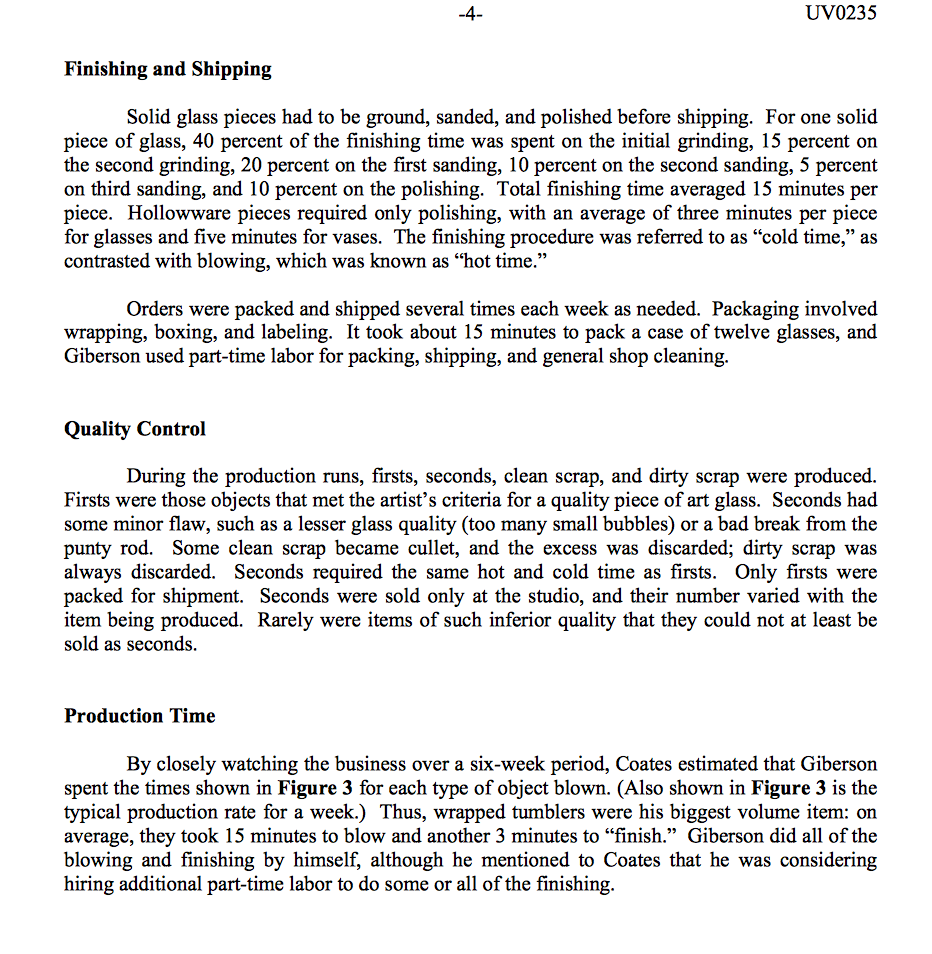

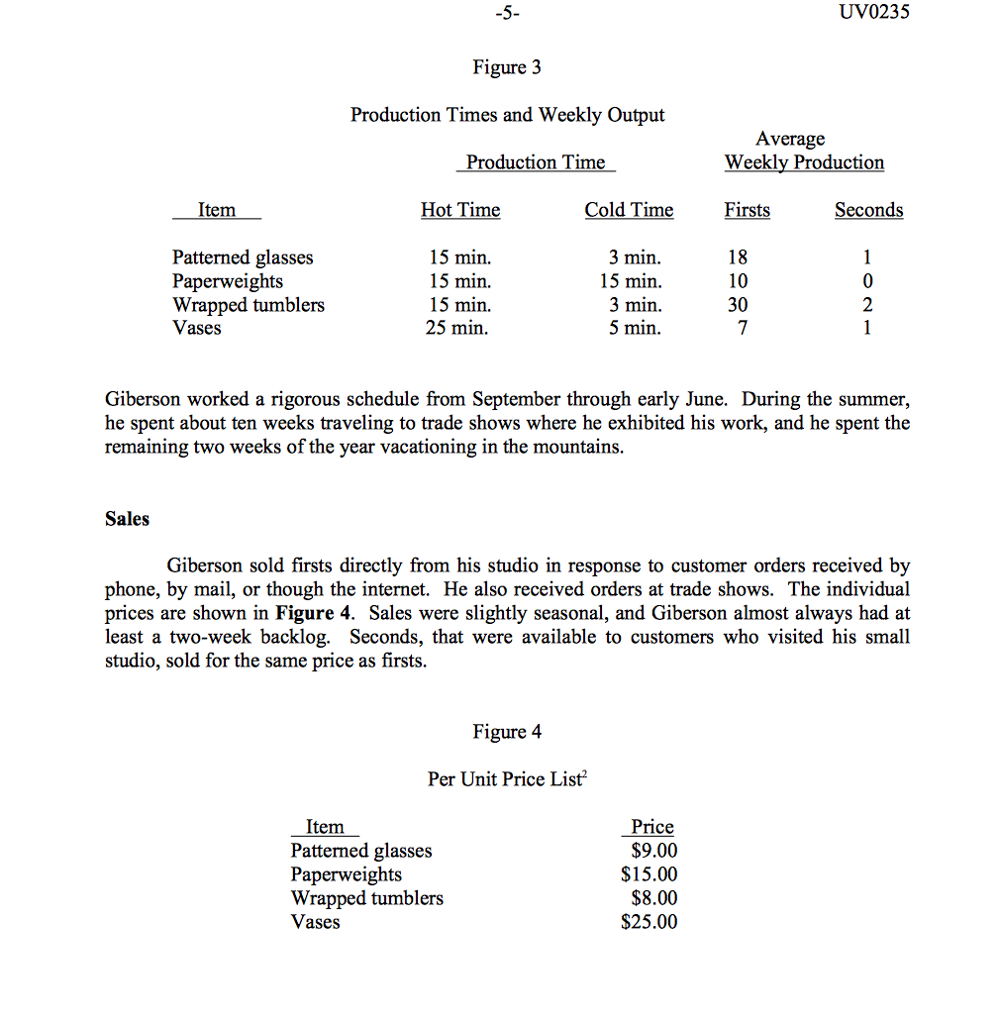

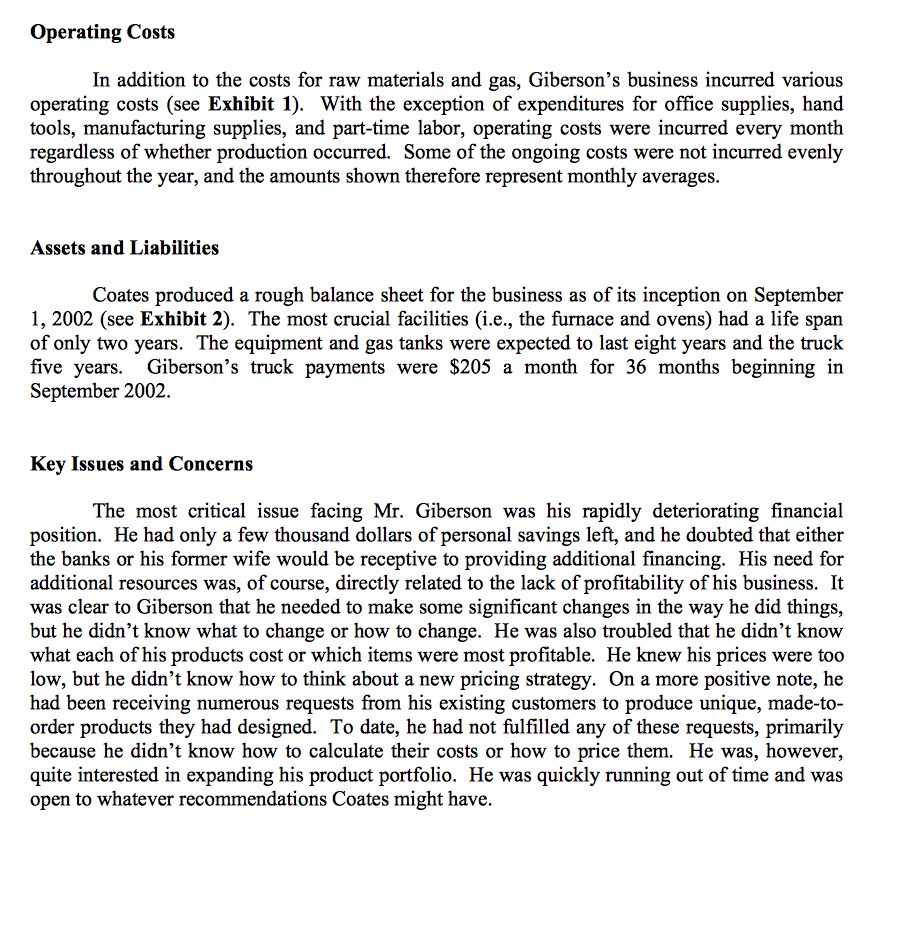

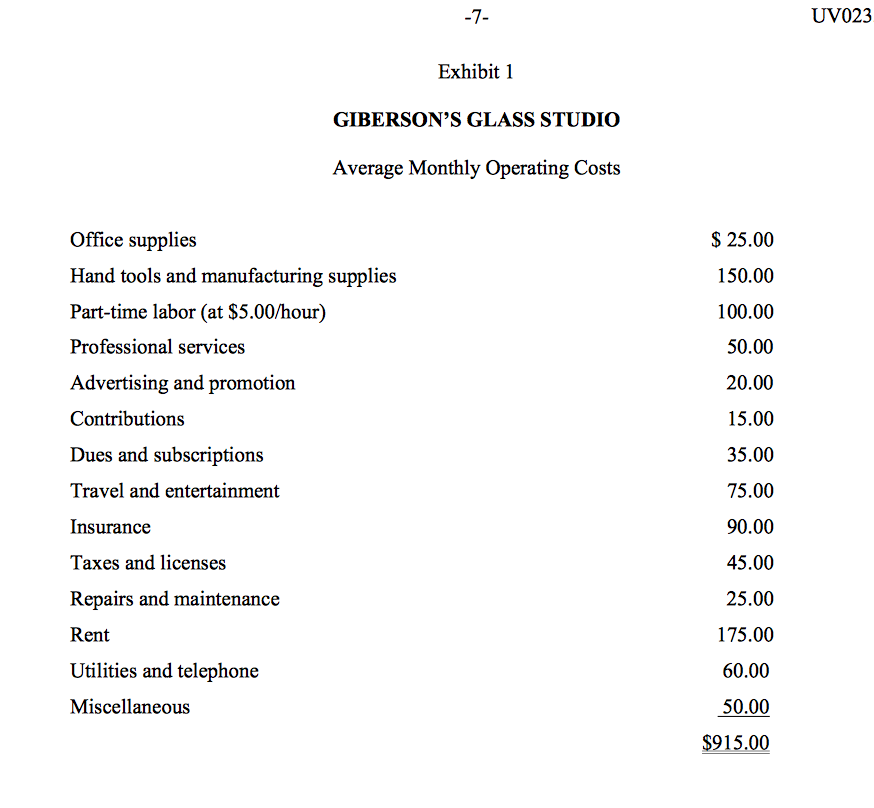

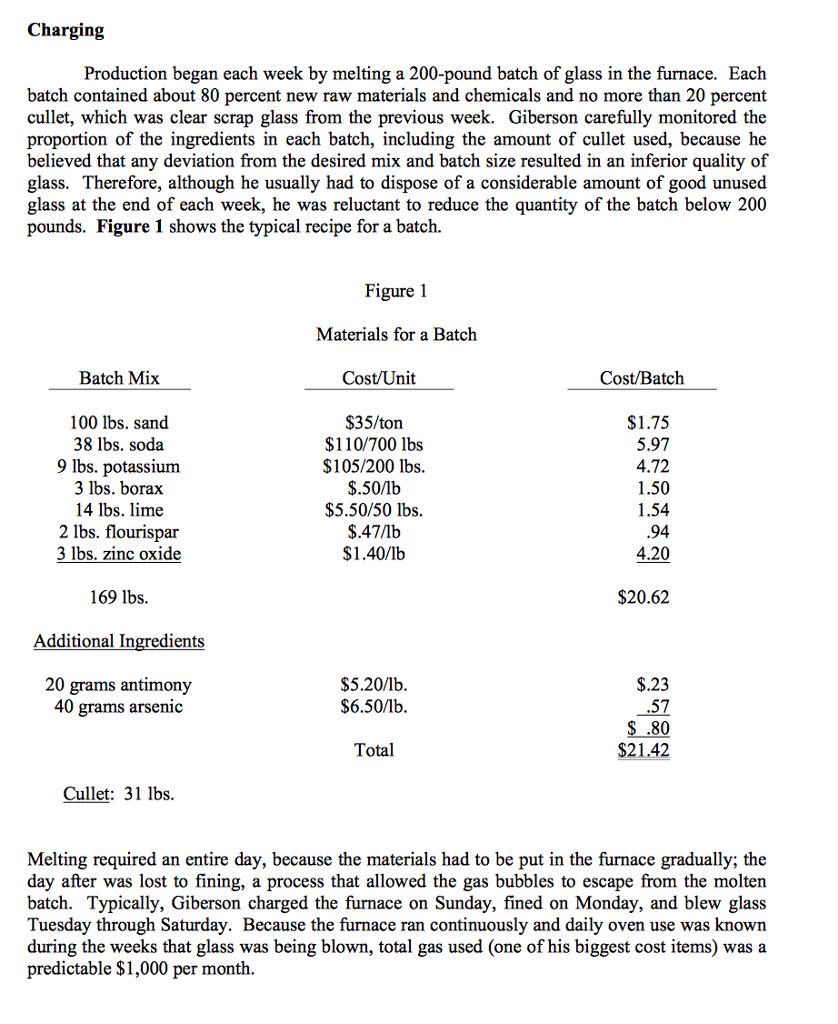

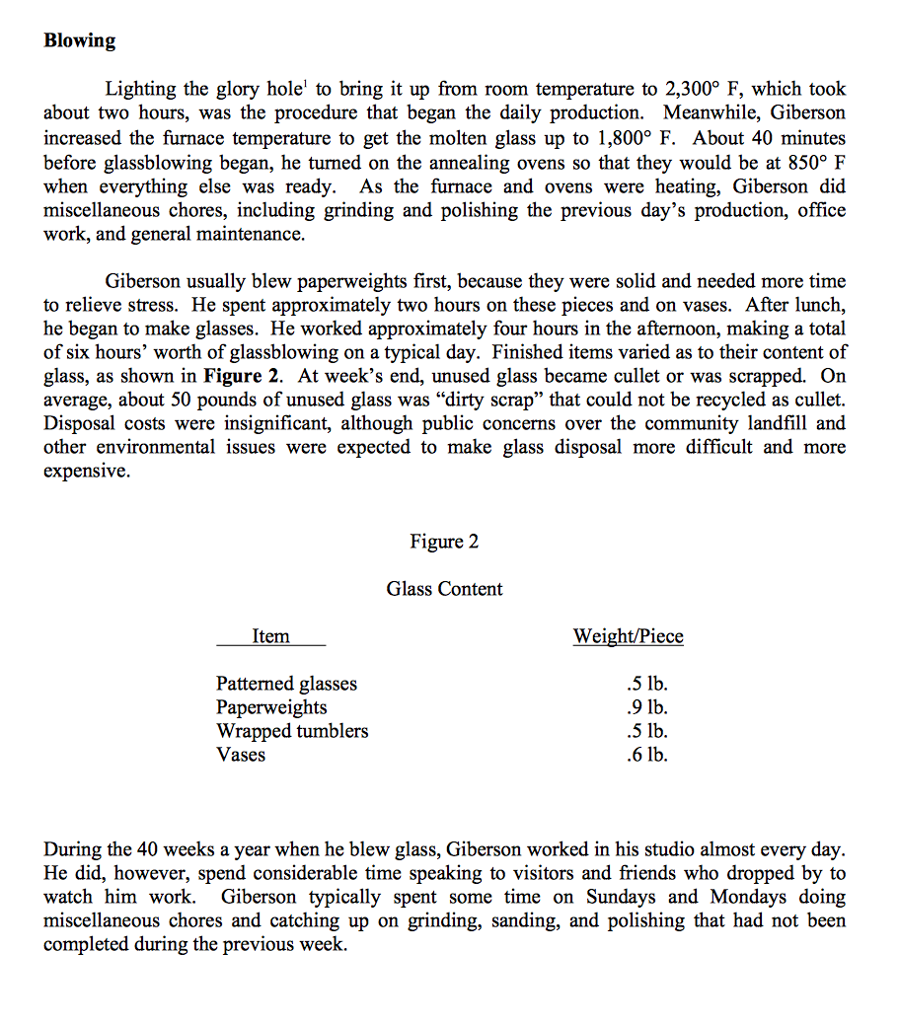

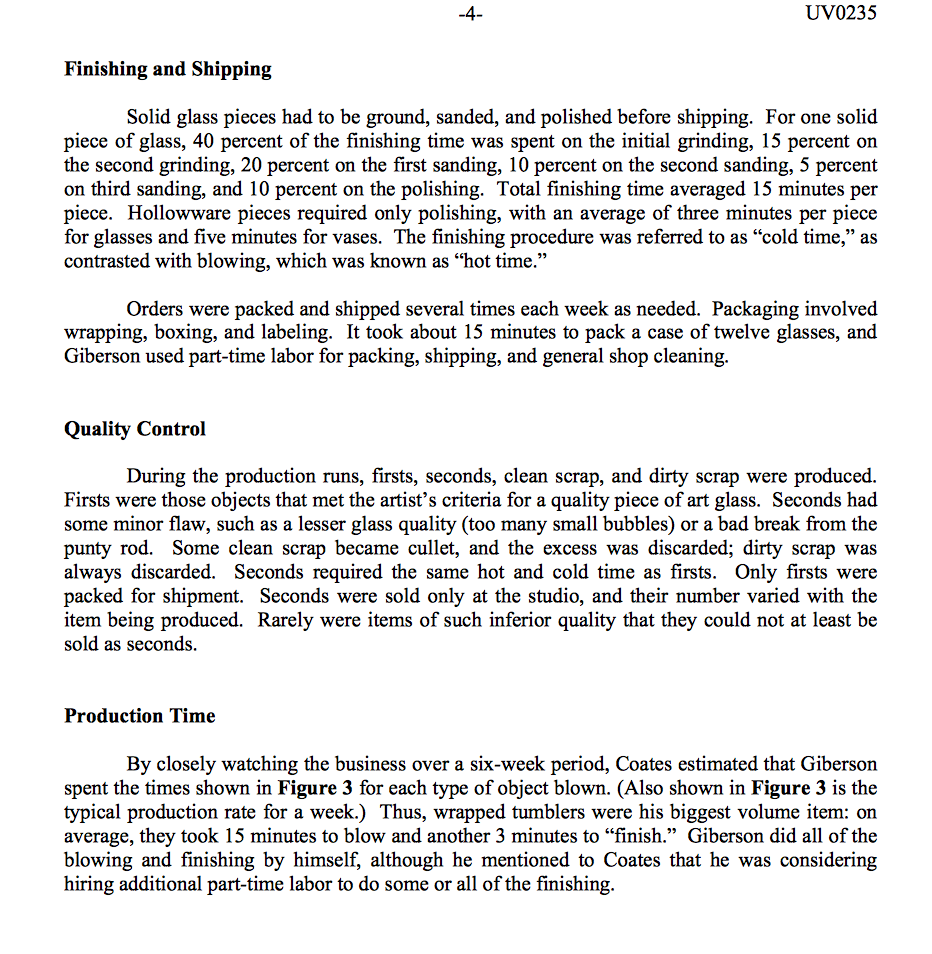

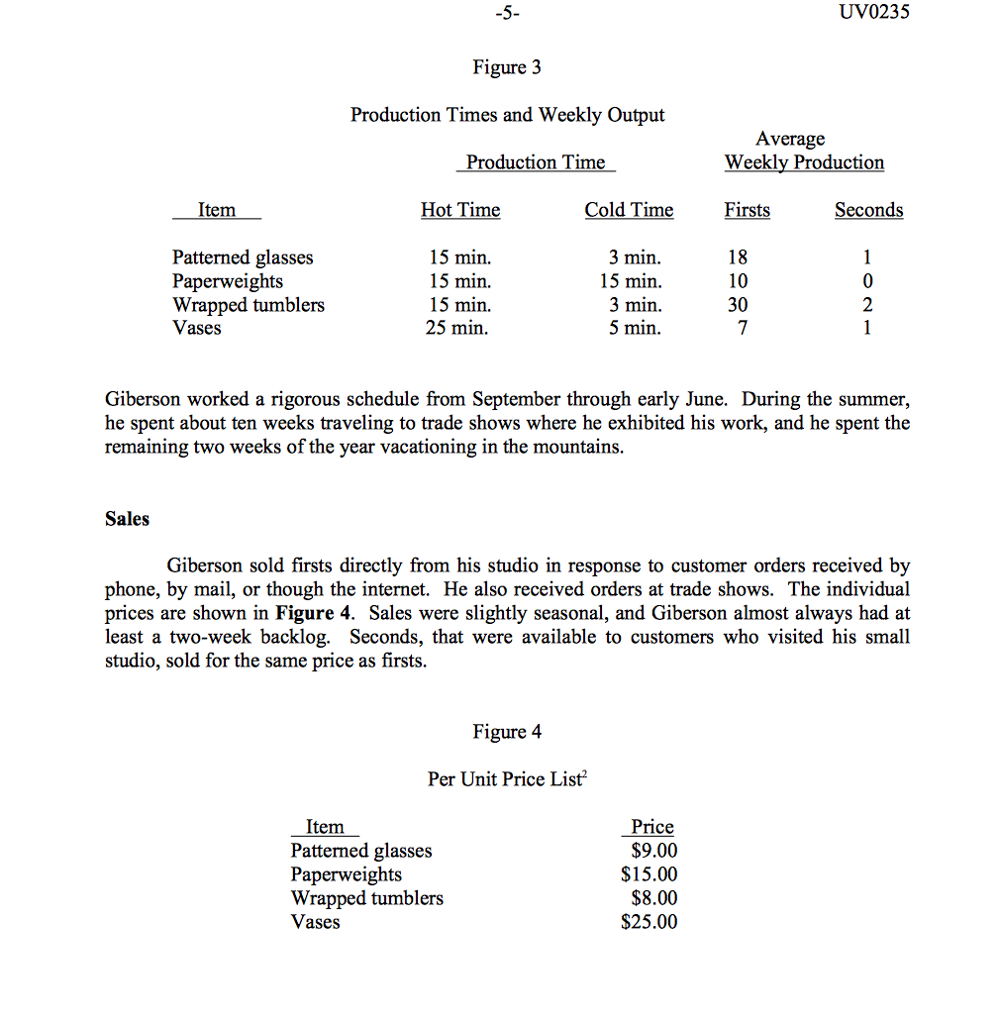

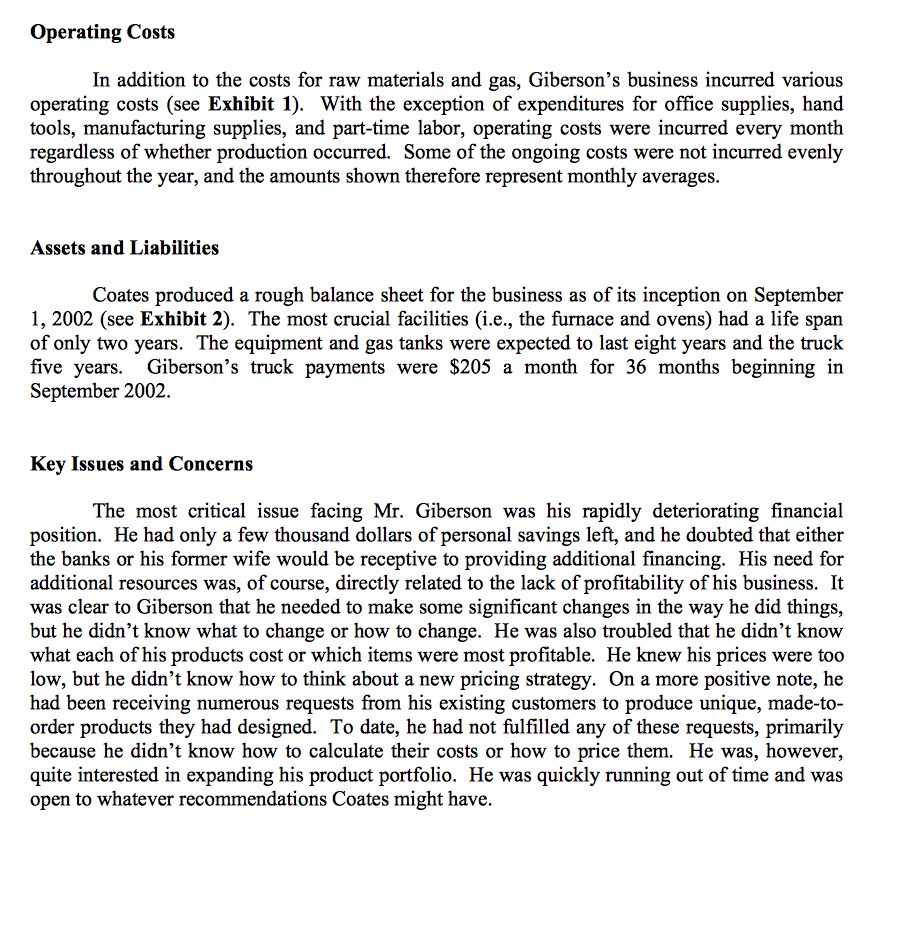

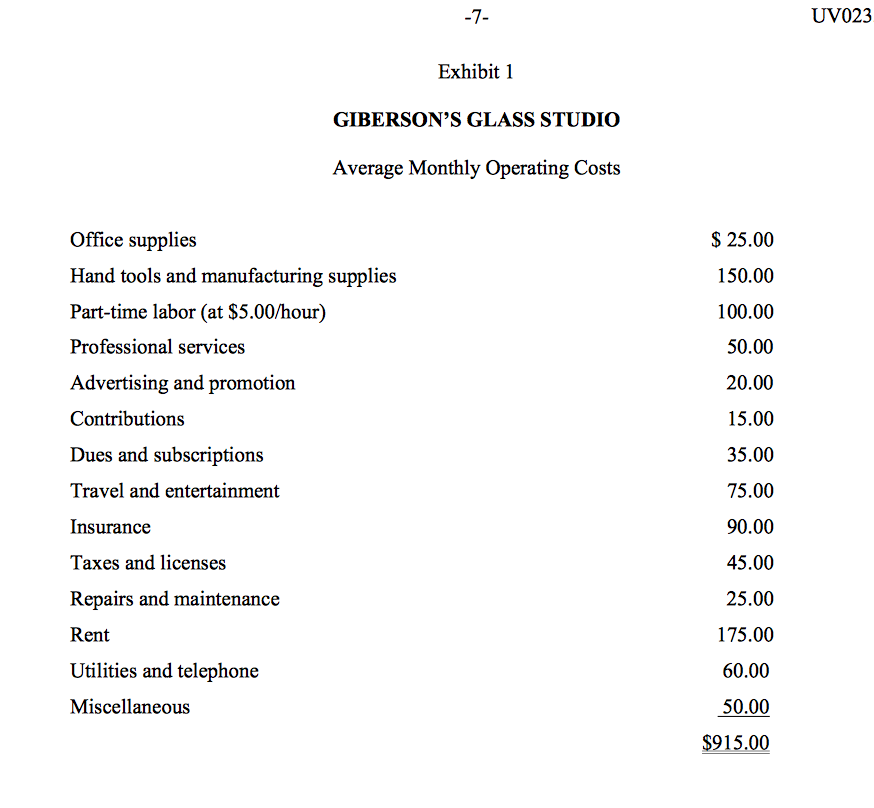

Charging Production began each week by melting a 200-pound batch of glass in the furnace. Each batch contained about 80 percent new raw materials and chemicals and no more than 20 percent cullet, which was clear scrap glass from the previous week. Giberson carefully monitored the proportion of the ingredients in each batch, including the amount of cullet used, because he believed that any deviation from the desired mix and batch size resulted in an inferior quality of glass. Therefore, although he usually had to dispose of a considerable amount of good unused glass at the end of each week, he was reluctant to reduce the quantity of the batch below 200 pounds. Figure 1 shows the typical recipe for a batch. Figure 1 Materials for a Batch Batch Mix Cost/Unit Cost/Batclh 100 lbs. sand 38 lbs. soda 9 lbs. potassium 3 lbs. borax 14 lbs. lime 2 lbs. flourispar 3 lbs. zinc oxide S35/ton $110/700 lbs $105/200 lbs $.50/lb $5.50/50 lbs $.47/1b $1.40/lb $1.75 5.97 4.72 1.50 1.54 .94 4.20 169 lbs $20.62 dditional Ingredients 20 grams antimony 40 grams arsenic $.23 57 $ .80 $21.42 S5.20/lb $6.50/lb Total Cullet: 31 lbs Melting required an entire day, because the materials had to be put in the furnace gradually; the day after was lost to fining, a process that allowed the gas bubbles to escape from the molten batch. Typically, Giberson charged the furnace on Sunday, fined on Monday, and blew glass Tuesday through Saturday. Because the furnace ran continuously and daily oven use was known during the weeks that glass was being blown, total gas used (one of his biggest cost items) was a predictable $1,000 per month Charging Production began each week by melting a 200-pound batch of glass in the furnace. Each batch contained about 80 percent new raw materials and chemicals and no more than 20 percent cullet, which was clear scrap glass from the previous week. Giberson carefully monitored the proportion of the ingredients in each batch, including the amount of cullet used, because he believed that any deviation from the desired mix and batch size resulted in an inferior quality of glass. Therefore, although he usually had to dispose of a considerable amount of good unused glass at the end of each week, he was reluctant to reduce the quantity of the batch below 200 pounds. Figure 1 shows the typical recipe for a batch. Figure 1 Materials for a Batch Batch Mix Cost/Unit Cost/Batclh 100 lbs. sand 38 lbs. soda 9 lbs. potassium 3 lbs. borax 14 lbs. lime 2 lbs. flourispar 3 lbs. zinc oxide S35/ton $110/700 lbs $105/200 lbs $.50/lb $5.50/50 lbs $.47/1b $1.40/lb $1.75 5.97 4.72 1.50 1.54 .94 4.20 169 lbs $20.62 dditional Ingredients 20 grams antimony 40 grams arsenic $.23 57 $ .80 $21.42 S5.20/lb $6.50/lb Total Cullet: 31 lbs Melting required an entire day, because the materials had to be put in the furnace gradually; the day after was lost to fining, a process that allowed the gas bubbles to escape from the molten batch. Typically, Giberson charged the furnace on Sunday, fined on Monday, and blew glass Tuesday through Saturday. Because the furnace ran continuously and daily oven use was known during the weeks that glass was being blown, total gas used (one of his biggest cost items) was a predictable $1,000 per month