Question: 1. Write a discussion article (1 page) 2. Discussion content may consist of - Summary of problems studied and purpose of the article - A

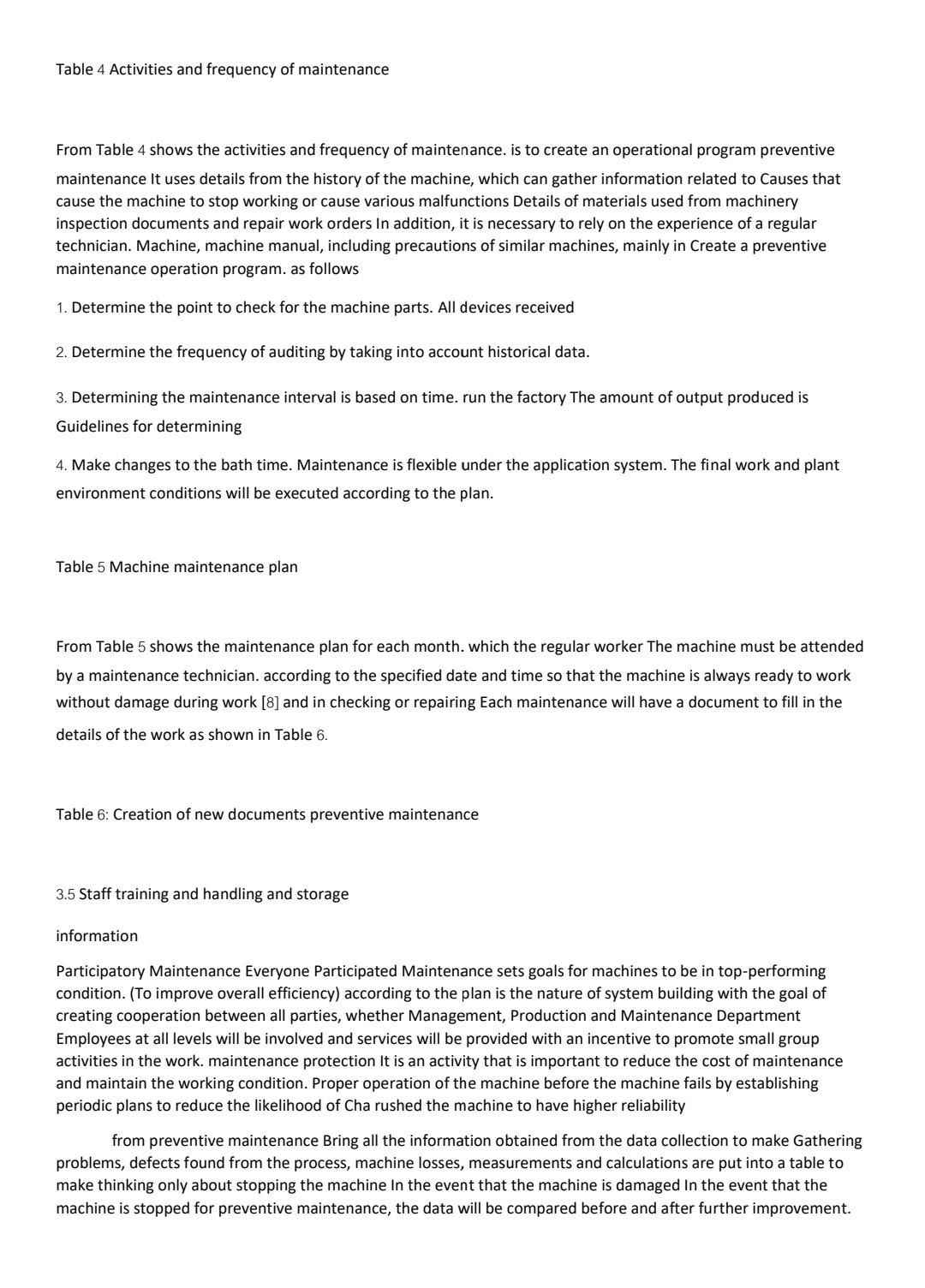

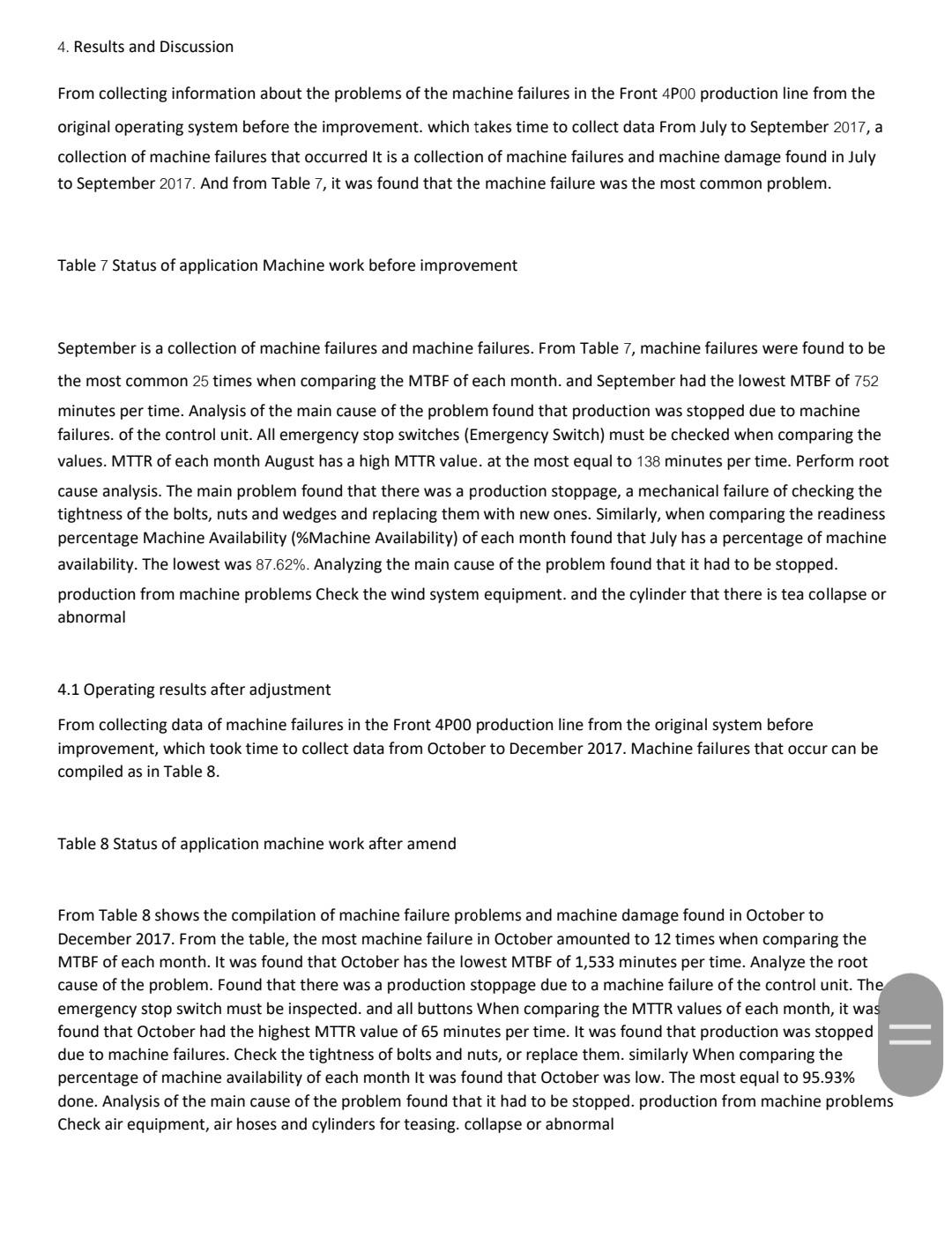

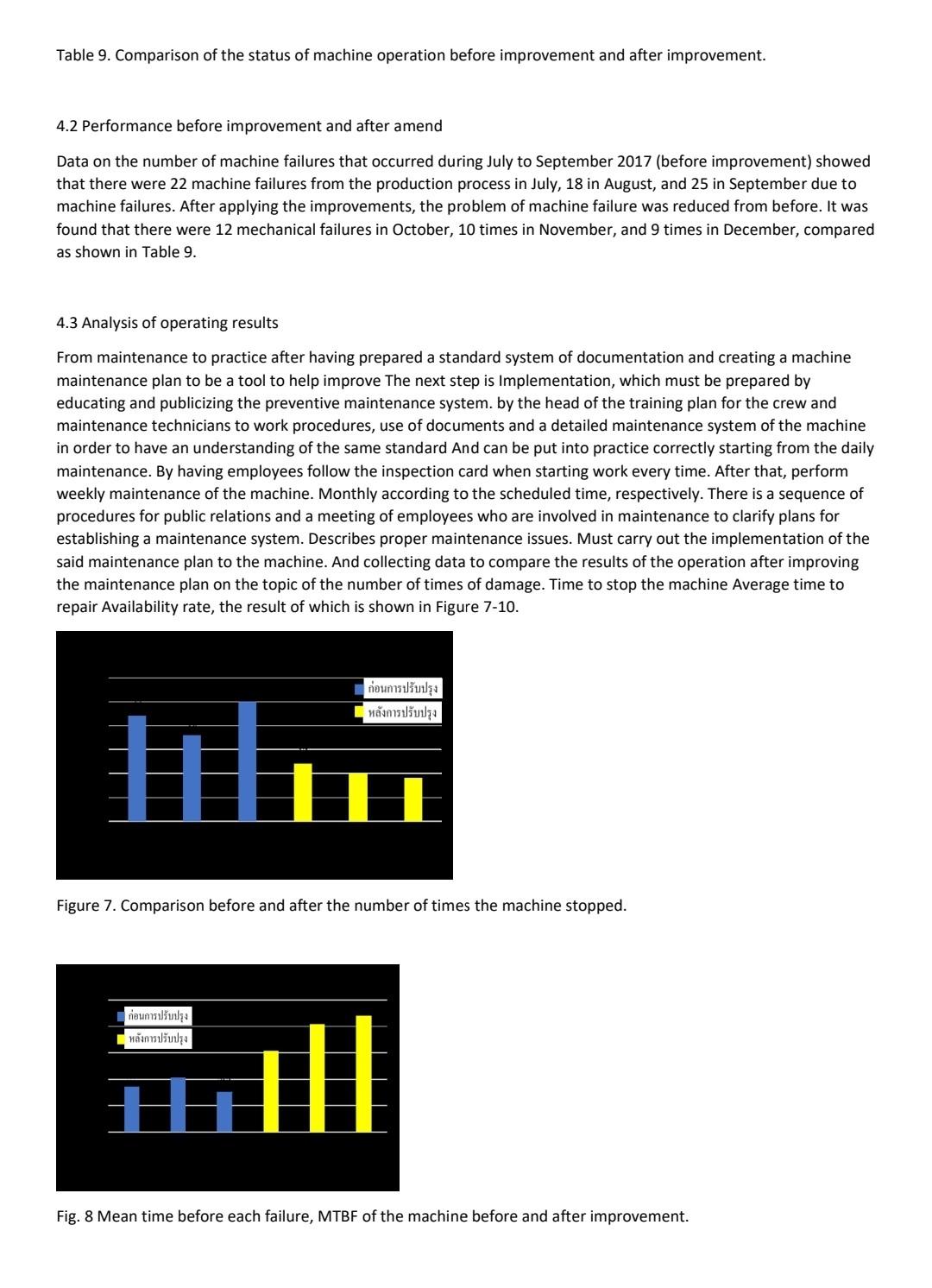

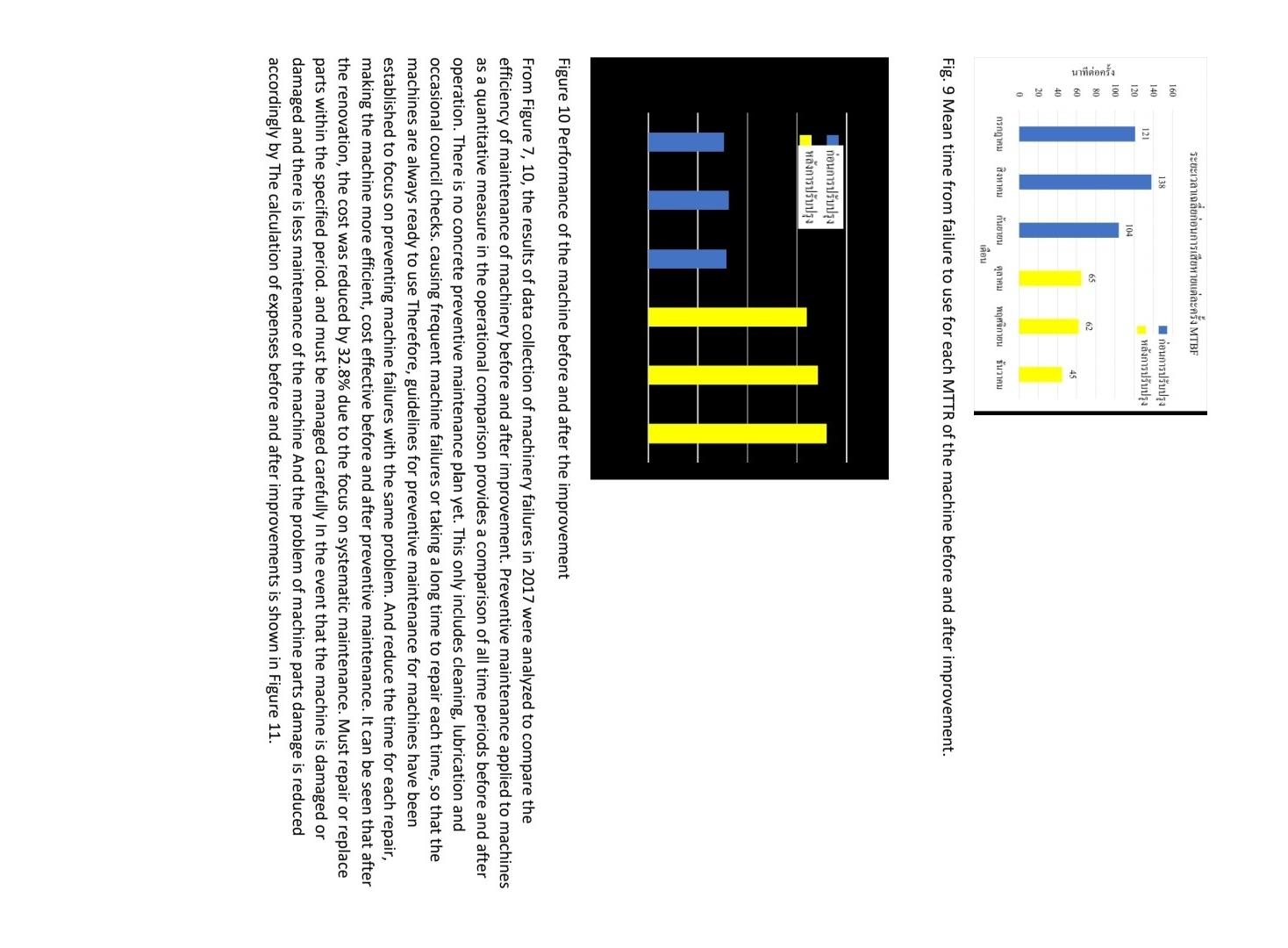

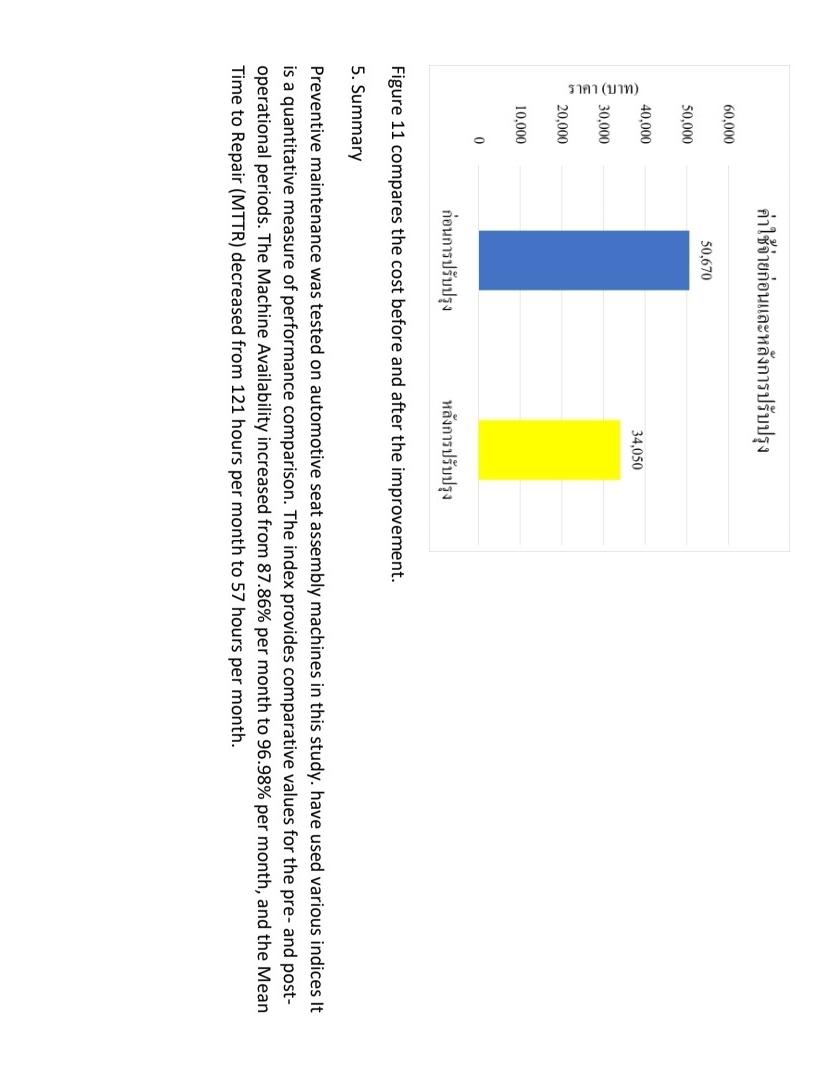

1. Write a discussion article (1 page) 2. Discussion content may consist of - Summary of problems studied and purpose of the article - A brief summary of the study process and case studies. - Key conclusions from the study - Comments on articles such as - Is the article reasonable, surprising, significant, etc.?; - Explain the connection between the methods used in this paper and the content in the class. - Do you agree with the methods used and the results from the study? Why, what could be improved on this article? Etc. Preventive Maintenance Case Study : Car Seat Manufacturing Company Abstract The objective of this research paper is to reduce the machine failure in car seat production process due to high production rate and lack of maintenance method. Therefore, the researcher proposed the preventive maintenance method for improving the efficiency of the operation machine using obtained data of the machine maintenance period. As a result, the machine availability is increased from 87.86% per month to 96.98% per month and the mean time to repair (MTTR) is decreased from 121 hours per month to 57 hours per month and the mean time between failures (MTBF) is increased from 878.6 hours per month to 1,920 hours per month. The average of damaged value is decreased from 50,670 baht per month to 34,050 baht per month, when applying the preventive maintenance method in the car seat production line. Keywords: Maintenance, Predictions, Machine Performance 1. Introduction Improving production efficiency or expanding production capacity of each company has different policies. The most popular approach is to buy high-efficiency and modern machines to be used in the production process. When investing in new machinery, management must calculate the break-even point. with regard to wear Or damaged to the extent that repairs occur [1] from a case study of a sample company. Car seat manufacturing is a company that operates in the production. It cannot be denied that machinery is one of the important production factors. Contributes to the production of products to meet the needs of customers accurately and quickly. Maintenance of machines to be ready for use at all times is therefore very important that must be carried out in conjunction with production. But one of the main problems that is important to the work of machine maintenance is the inability to predict whether a machine or its components Will last a lot less to deteriorate Therefore, operators solve this problem by replacing or repairing parts. According to the time specified in the instruction manual of the machine [2], but when the machine or various components been used for a long time, the maintenance plan according to the manual may not affect the efficient operation of the machine. and may also result in subsequent damage to the machine as well The researcher considers such problems, therefore establishes preventive maintenance standards (Preventive Maintenance: PM) of the machinery [3] and then analyzes the problem conditions and solutions correctly and appropriately. to improve the machine to be in working condition By increasing Mean Time To Failure (MTBF) and decreasing Mean Time To Repair (MTTR) and increasing overall machine productivity [4]. 2. Related theory 2.1 Preventive Maintenance (Preventive Main -tenance) Implementation of scheduled maintenance activities The time before the machine is damaged Prevents emergency stop of the machine This can be done by checking the machine condition. Proper cleaning and lubrication Adjustment to the machine at the working point according to the instructions of the manual, including scheduled maintenance and replacement of spare parts, such as replacing bearings. Drain engine oil, grease, etc. Preventive Maintenance (PM) is a planning by specifying a period of replacement of spare parts or overhaul to prevent damage that will occur. without having to stop using it in an emergency More planning for maintenance and utilization of assets is possible than corrective maintenance. Note: Generally, it is not foreseen and there is a lack of information to estimate the useful life of the asset. increased risk of damage occurring after maintenance work Both the efficiency and effectiveness of the maintenance plan according to the manufacturer's manual. 2.2 Measurement of maintenance effectiveness Calculation of Mean Time Between Failures (MTBF) 2.3 Related research [5] The rate of machine failure has been reduced. A case study of maintenance work in the jewelry and gem production line. It focuses on studying how to manage maintenance work in the jewelry or jewelry industry that produces silverware and to reduce machine failure and increase the Mean Time Between Failure, MTBF. ) by focusing on machines that directly affect the production process The research methodology has the following steps: gather machine data. It uses the approach of 7QC Tools and applies the principles of total productive maintenance (TPM) as well as problem analysis using the Why Why Analysis method to help finding solutions to machine problems The results from the calculation of the effectiveness of machinery in this research were to measure the availability of machinery from MTBF and MTTR methods. The calculation results showed that the rate of machine failure was less than the average MTBF. 87 minutes increase 142.4\% percentage increase, 21 minute decrease in average MTTR, 68.9% pre-improvement and 84% post-improvement availability, 15.1% increase relative to availability. In use in 2017, there was an increase of 121.9% and found that the rate of machine failure decreased by 0.00155 times per minute. [6] Development of a maintenance system for a medical packaging factory in Chachoengsao Province This research has developed a maintenance system of a medical packaging factory in Chachoengsao Province. The study found that it took a long time to repair the machine from a sudden failure in the blowing department of the plastic department, affecting production. In addition, there is no management to control spare parts, resulting in waiting for spare parts to repair the machine. and there is no preventive maintenance plan by making improvements and developed a maintenance system for 5 machines in the blow molding unit of the plastics department, namely PB3000/2A, PB3000/1, PB1000/2A, PB1000/2B and PB1000/1 respectively. Preventive Maintenance to calculate the average time between failures. and calculate the average maintenance time for planning the replacement of parts before a failure occurs so that the overall efficiency of the machine is in accordance with the specified target not less than 80 percent. The mean time between failures increased from 1,483.92 hours to 2,522.16 hours and the mean duration The maintenance time decreased from 26.63 hours to 0 hours and the time to repair the blow molding machine decreased from 411.67 hours to 61.33 hours, which could increase the overall efficiency of the machine from 66.52 percent to 82.46 percent. [7] Planning for preventive maintenance of machinery in the relay industry This research studied the preparation of a preventive maintenance plan for the relay industry manufactured in Thailand. From the preliminary study, it was found that the sample factory did not have a maintenance management system. Maintenance would be carried out only when the machinery stopped working on site. and proposed a preventive maintenance system and implement the system to compare the results before implementation and after the operation found that Mean Time Between Failures increased on average to 215.42 percent from the original The average maintenance time decreased to 73.91 percent from the previous average. The availability of the machine was 18.67 percent and the failure rate was reduced by 35.89 percent. 3. Research methods 3.1 Working process of the sample machine The study of the method of upholstery production process in the company used as a case study. And study the work process from receiving raw materials to producing finished work. For understanding before analyzing the defects that cause problems [8] according to the production process as in Figure 1 and Flow Chart of the maintenance process before improvement as in Figure 2 Assembling the seat will use a car seat assembly machine which is responsible for assembling the steel frame of the backrest seat with the foam pad. By tightening the bolts with the M/C FR4PO0 machine to set the automatic tightening. Belongs to THAI TECHNOLOGY AND SOLUTIONS Co., Ltd. has designed and manufactured the M/C FR4POO SAB Assembly Fixture RH1 machine to work in 2 systems: automatic and normal systems. In operation of the machine, the M/C FR4P00 SAB Assembly Fixture RH1 will use 220VAC as the internal power supply and there will be 24VDC as the internal control system of the M/C FR4P00 SAB Assembly. 3.2 Current condition of doing maintenance activities From the study of the data, the cause can be analyzed. of the problem of the occurrence of loss of production time of the machine and the cause of machine damage by Use a fishbone chart. and downtime information Machine The researcher has developed only the downtime of the machine only in case the machine is damaged History of machine repairs before using the system Maintenance according to the factory's problem survey condition Before applying, the preventive maintenance system consists of Data on the number of times of machine damage Time lost due to crashes and damage of machines during production (Breakdown Time) Mean Time Between Failure (MTBF) and Machine availability rate from month JulySeptember 2017 From a case study of a car seat factory between July-September 2017, it was found that the process Automobile seat manufacturers have the problem of value for the availability of Machine (M/C FR4P00 SAB Assembly Fixture RH1) is relatively low than the target, with the average target of the company being 96.98% per month, but the current Ready to use the machine (M/C FR4P00 SAB Assembly Fixture RH1) is at 87.86% per month because caused by frequent machine failures From Table 1 shows maintenance activities. A preventive maintenance action plan that will be Detailed description of all operations by division Work of all types of machines, maintenance activities In each type of work is divided into cleaning. normal machine operation, check condition and Customize and change parts, there are 10 activities that must be practiced in which each activity will have principles practice for ba Preliminary maintenance of the machine that can be will lead to repair can be cooked in time before the machine damaged more than before The staff who operates the machine will know that Machines are in perfect condition and damage can be reported. A handyman can do repairs. From Table 2 shows Why Why analysis. Analysis [8] will analyze the cause of the problem. If we can discover the cause and the original problem. This often means that our analysis is misdirected or not. There may be some causes missing that may need to be analyzed. New This tool is very powerful. analytics, insight and expertise, including Engineering knowledge is used as the main tool to analyze the problem and found that most of the principles Why Why Analysis is just the same problem still occurs. Repeatedly, relying only on increasing frequency, which Causing waste to follow. Making that problem out. Therefore, it is necessary to apply other principles. additional assembly From problem analysis using fishbone chart [11], it was found that the machine had major problems from factors of decay device condition Continuous use for a long time and lack of maintenance staff lacking training There is no proper maintenance system. And the case study factory does not have an orderly assortment of spare parts. The amount of remaining spare parts is not known, causing damage to the machine often [12]. 3.3 Establish a maintenance plan [10] Due to the state of the problem that occurred in the production line of the repair line factory plant case study which causes an impact on the production system of the factory from the root cause of the problems mentioned above The problem can be concluded that the lack of a proper maintenance management plan to support the machine in the production line is not in a condition that can work at maximum efficiency. Machine maintenance planning will consist of the following main steps: 3.4 Preparation of system structure Engineering department is responsible for planning, controlling and operating directly in the field of maintenance [9] both in terms of scheduled maintenance. and emergency inspection of machinery It also includes design. and choose materials that are easy to maintain, which can show the job description of each individual In this step, it will prepare for the creation of an operating system consisting of the main tasks. 1. Organization of maintenance It is a job that is of first importance. in order to create an agency to support the maintenance system Although the current situation has already allocated personnel to work. But in terms of management, there has not been a clear organizational system in terms of controlling reporting that is clearly structured. And in order to give importance to maintenance work, the agency established to take responsibility for this work should have the status of a division level agency. There is a department head who reports directly to the factory manager. The engineering department is divided into 3 departments: Planned Maintenance Department is responsible for the preparation and improvement of preventive maintenance plans. Make a schedule to check the machine condition. Prepare machine history data and control the spare parts warehouse system of the maintenance department and electrical maintenance department Responsible for the operations of machine inspections, electrical maintenance operations [8] as shown in Figure 5. 2. Controlling the maintenance of the system of documents used in maintenance. From Table 3 shows the maintenance activities, the preventive maintenance operation plan details the details of all operations. By dividing the work of the machine into types of maintenance activities. Each type of work is divided into cleaning, lubrication, inspection, adjustment and replacement of parts, of which there are 9 activities to be performed. In which each activity will have a practice principle for ba Initial maintenance of the machine That can lead to timely maintenance before the machine is slow. This means that operators will know whether the machine is in perfect condition or slow down. Rud can notify a repairman to come and fix it [10] Table 3 Maintenance Activities Table 4 Activities and frequency of maintenance From Table 4 shows the activities and frequency of maintenance. is to create an operational program preventive maintenance It uses details from the history of the machine, which can gather information related to Causes that cause the machine to stop working or cause various malfunctions Details of materials used from machinery inspection documents and repair work orders In addition, it is necessary to rely on the experience of a regular technician. Machine, machine manual, including precautions of similar machines, mainly in Create a preventive maintenance operation program. as follows 1. Determine the point to check for the machine parts. All devices received 2. Determine the frequency of auditing by taking into account historical data. 3. Determining the maintenance interval is based on time. run the factory The amount of output produced is Guidelines for determining 4. Make changes to the bath time. Maintenance is flexible under the application system. The final work and plant environment conditions will be executed according to the plan. Table 5 Machine maintenance plan From Table 5 shows the maintenance plan for each month. which the regular worker The machine must be attended by a maintenance technician. according to the specified date and time so that the machine is always ready to work without damage during work [8] and in checking or repairing Each maintenance will have a document to fill in the details of the work as shown in Table 6 . Table 6: Creation of new documents preventive maintenance 3.5 Staff training and handling and storage information Participatory Maintenance Everyone Participated Maintenance sets goals for machines to be in top-performing condition. (To improve overall efficiency) according to the plan is the nature of system building with the goal of creating cooperation between all parties, whether Management, Production and Maintenance Department Employees at all levels will be involved and services will be provided with an incentive to promote small group activities in the work. maintenance protection It is an activity that is important to reduce the cost of maintenance and maintain the working condition. Proper operation of the machine before the machine fails by establishing periodic plans to reduce the likelihood of Cha rushed the machine to have higher reliability from preventive maintenance Bring all the information obtained from the data collection to make Gathering problems, defects found from the process, machine losses, measurements and calculations are put into a table to make thinking only about stopping the machine In the event that the machine is damaged In the event that the machine is stopped for preventive maintenance, the data will be compared before and after further improvement. 4. Results and Discussion From collecting information about the problems of the machine failures in the Front 4P00 production line from the original operating system before the improvement. which takes time to collect data From July to September 2017 , a collection of machine failures that occurred It is a collection of machine failures and machine damage found in July to September 2017. And from Table 7, it was found that the machine failure was the most common problem. Table 7 Status of application Machine work before improvement September is a collection of machine failures and machine failures. From Table 7 , machine failures were found to be the most common 25 times when comparing the MTBF of each month. and September had the lowest MTBF of 752 minutes per time. Analysis of the main cause of the problem found that production was stopped due to machine failures. of the control unit. All emergency stop switches (Emergency Switch) must be checked when comparing the values. MTTR of each month August has a high MTTR value. at the most equal to 138 minutes per time. Perform root cause analysis. The main problem found that there was a production stoppage, a mechanical failure of checking the tightness of the bolts, nuts and wedges and replacing them with new ones. Similarly, when comparing the readiness percentage Machine Availability (\%Machine Availability) of each month found that July has a percentage of machine availability. The lowest was 87.62%. Analyzing the main cause of the problem found that it had to be stopped. production from machine problems Check the wind system equipment. and the cylinder that there is tea collapse or abnormal 4.1 Operating results after adjustment From collecting data of machine failures in the Front 4PO0 production line from the original system before improvement, which took time to collect data from October to December 2017. Machine failures that occur can be compiled as in Table 8. Table 8 Status of application machine work after amend From Table 8 shows the compilation of machine failure problems and machine damage found in October to December 2017. From the table, the most machine failure in October amounted to 12 times when comparing the MTBF of each month. It was found that October has the lowest MTBF of 1,533 minutes per time. Analyze the root cause of the problem. Found that there was a production stoppage due to a machine failure of the control unit. Th emergency stop switch must be inspected. and all buttons When comparing the MTTR values of each month, it wa: found that October had the highest MTTR value of 65 minutes per time. It was found that production was stopped due to machine failures. Check the tightness of bolts and nuts, or replace them. similarly When comparing the percentage of machine availability of each month It was found that October was low. The most equal to 95.93% done. Analysis of the main cause of the problem found that it had to be stopped. production from machine problems Check air equipment, air hoses and cylinders for teasing. collapse or abnormal 4.2 Performance before improvement and after amend Data on the number of machine failures that occurred during July to September 2017 (before improvement) showed that there were 22 machine failures from the production process in July, 18 in August, and 25 in September due to machine failures. After applying the improvements, the problem of machine failure was reduced from before. It was found that there were 12 mechanical failures in October, 10 times in November, and 9 times in December, compared as shown in Table 9. 4.3 Analysis of operating results From maintenance to practice after having prepared a standard system of documentation and creating a machine maintenance plan to be a tool to help improve The next step is Implementation, which must be prepared by educating and publicizing the preventive maintenance system. by the head of the training plan for the crew and maintenance technicians to work procedures, use of documents and a detailed maintenance system of the machine in order to have an understanding of the same standard And can be put into practice correctly starting from the daily maintenance. By having employees follow the inspection card when starting work every time. After that, perform weekly maintenance of the machine. Monthly according to the scheduled time, respectively. There is a sequence of procedures for public relations and a meeting of employees who are involved in maintenance to clarify plans for establishing a maintenance system. Describes proper maintenance issues. Must carry out the implementation of the said maintenance plan to the machine. And collecting data to compare the results of the operation after improving the maintenance plan on the topic of the number of times of damage. Time to stop the machine Average time to repair Availability rate, the result of which is shown in Figure 7-10. Figure 7. Comparison before and after the number of times the machine stopped. Fig. 8 Mean time before each failure, MTBF of the machine before and after improvement. Fig. 9 Mean time from failure to use for each MTTR of the machine before and after improvement. Figure 10 Performance of the machine before and after the improvement From Figure 7, 10, the results of data collection of machinery failures in 2017 were analyzed to compare the efficiency of maintenance of machinery before and after improvement. Preventive maintenance applied to machines as a quantitative measure in the operational comparison provides a comparison of all time periods before and after operation. There is no concrete preventive maintenance plan yet. This only includes cleaning, lubrication and occasional council checks. causing frequent machine failures or taking a long time to repair each time, so that the machines are always ready to use Therefore, guidelines for preventive maintenance for machines have been established to focus on preventing machine failures with the same problem. And reduce the time for each repair, making the machine more efficient, cost effective before and after preventive maintenance. It can be seen that after the renovation, the cost was reduced by 32.8% due to the focus on systematic maintenance. Must repair or replace parts within the specified period. and must be managed carefully In the event that the machine is damaged or damaged and there is less maintenance of the machine And the problem of machine parts damage is reduced accordingly by The calculation of expenses before and after improvements is shown in Figure 11. Figure 11 compares the cost before and after the improvement. 5. Summary Preventive maintenance was tested on automotive seat assembly machines in this study. have used various indices It is a quantitative measure of performance comparison. The index provides comparative values for the pre- and postoperational periods. The Machine Availability increased from 87.86% per month to 96.98% per month, and the Mean Time to Repair (MTTR) decreased from 121 hours per month to 57 hours per month

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts