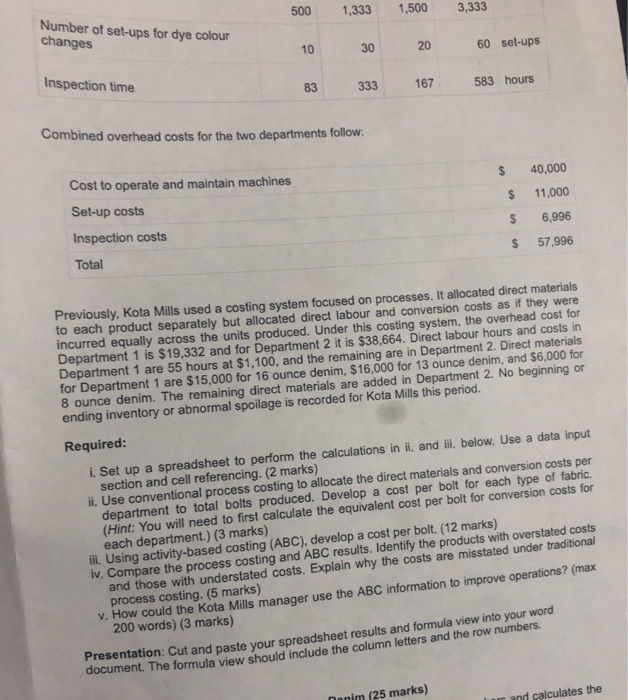

10. Alleina live submission method TASK Background In this assignment, you are still working with Helen Croker of Divine Denim and also win management of Kota Mills, a denim weaver. Question 1 Activity Based Costing for Kota Mills (25 marks) Kota Mills supply Divine Denim with the organic denim used in their production. After discussions with Helen about the service she was getting from Good Numbers, the manager of Kota Mills decided to use Good Numbers to assist with their management decision making. Kota Mills produces three different weights of denim using two departments. In Department 1, machines weave the cloth. In Department 2 the cloth is dyed a variety of colours. Information for the combined use of resources in both departments for the three types of fabric is outlined below. Bolts are 20 metres each. All fabric is inspected during production. Robotic equipment inspects the fabric for obvious flaws as the bolts are wound up. Each bolt spends about 5 minutes in the inspection process. Denim 8 ounce 16 13 ounce ounce Total units Monthly production in units (bolts of fabric) 1,000 4,000 2,000 7,000 bolts 8,000 Direct material cost $ 24,000 20,000 52,000 $ 660 Direct labour cost $ 1,320 920 2,900 $ 33 66 46 Direct labour hours 145 hours Machine hours hours nemscourse_id=43907 1&modewi Number of set-ups for dye colour changes 500 10 83 1,333 30 333 1,500 20 167 3,333 60 set-ups 583 hours Inspection time Combined overhead costs for the two departments follow: Cost to operate and maintain machines $ $ $ $ 40,000 11,000 6,996 57,996 Set-up costs Inspection costs Total Previously, Kota Mills used a costing system focused on processes. It allocated direct materials to each product separately but allocated direct labour and conversion costs as if they were incurred equally across the units produced. Under this costing system, the overhead cost for Department 1 is $19,332 and for Department 2 it is $38,664. Direct labour hours and costs in Department 1 are 55 hours at $1,100, and the remaining are in Department 2. Direct materials for Department 1 are $15,000 for 16 ounce denim, $16,000 for 13 ounce denim, and $6,000 for 8 ounce denim. The remaining direct materials are added in Department 2. No beginning or ending inventory or abnormal spoilage is recorded for Kota Mills this period. Required: 1. Set up a spreadsheet to perform the calculations in ii. and ii, below. Use a data input section and cell referencing. (2 marks) ii. Use conventional process costing to allocate the direct materials and conversion costs per department to total bolts produced. Develop a cost per bolt for each type of fabric. (Hint: You will need to first calculate the equivalent cost per bolt for conversion costs for each department.) (3 marks) iii. Using activity-based costing (ABC), develop a cost per bolt. (12 marks) iv. Compare the process costing and ABC results. Identify the products with overstated costs and those with understated costs. Explain why the costs are misstated under traditional process costing. (5 marks) v. How could the Kota Mills manager use the ABC information to improve operations? (max 200 words) (3 marks) Presentation: Cut and paste your spreadsheet results and formula view into your word document. The formula view should include the column letters and the row numbers. Donim (25 marks) bar and calculates the 10. Alleina live submission method TASK Background In this assignment, you are still working with Helen Croker of Divine Denim and also win management of Kota Mills, a denim weaver. Question 1 Activity Based Costing for Kota Mills (25 marks) Kota Mills supply Divine Denim with the organic denim used in their production. After discussions with Helen about the service she was getting from Good Numbers, the manager of Kota Mills decided to use Good Numbers to assist with their management decision making. Kota Mills produces three different weights of denim using two departments. In Department 1, machines weave the cloth. In Department 2 the cloth is dyed a variety of colours. Information for the combined use of resources in both departments for the three types of fabric is outlined below. Bolts are 20 metres each. All fabric is inspected during production. Robotic equipment inspects the fabric for obvious flaws as the bolts are wound up. Each bolt spends about 5 minutes in the inspection process. Denim 8 ounce 16 13 ounce ounce Total units Monthly production in units (bolts of fabric) 1,000 4,000 2,000 7,000 bolts 8,000 Direct material cost $ 24,000 20,000 52,000 $ 660 Direct labour cost $ 1,320 920 2,900 $ 33 66 46 Direct labour hours 145 hours Machine hours hours nemscourse_id=43907 1&modewi Number of set-ups for dye colour changes 500 10 83 1,333 30 333 1,500 20 167 3,333 60 set-ups 583 hours Inspection time Combined overhead costs for the two departments follow: Cost to operate and maintain machines $ $ $ $ 40,000 11,000 6,996 57,996 Set-up costs Inspection costs Total Previously, Kota Mills used a costing system focused on processes. It allocated direct materials to each product separately but allocated direct labour and conversion costs as if they were incurred equally across the units produced. Under this costing system, the overhead cost for Department 1 is $19,332 and for Department 2 it is $38,664. Direct labour hours and costs in Department 1 are 55 hours at $1,100, and the remaining are in Department 2. Direct materials for Department 1 are $15,000 for 16 ounce denim, $16,000 for 13 ounce denim, and $6,000 for 8 ounce denim. The remaining direct materials are added in Department 2. No beginning or ending inventory or abnormal spoilage is recorded for Kota Mills this period. Required: 1. Set up a spreadsheet to perform the calculations in ii. and ii, below. Use a data input section and cell referencing. (2 marks) ii. Use conventional process costing to allocate the direct materials and conversion costs per department to total bolts produced. Develop a cost per bolt for each type of fabric. (Hint: You will need to first calculate the equivalent cost per bolt for conversion costs for each department.) (3 marks) iii. Using activity-based costing (ABC), develop a cost per bolt. (12 marks) iv. Compare the process costing and ABC results. Identify the products with overstated costs and those with understated costs. Explain why the costs are misstated under traditional process costing. (5 marks) v. How could the Kota Mills manager use the ABC information to improve operations? (max 200 words) (3 marks) Presentation: Cut and paste your spreadsheet results and formula view into your word document. The formula view should include the column letters and the row numbers. Donim (25 marks) bar and calculates the