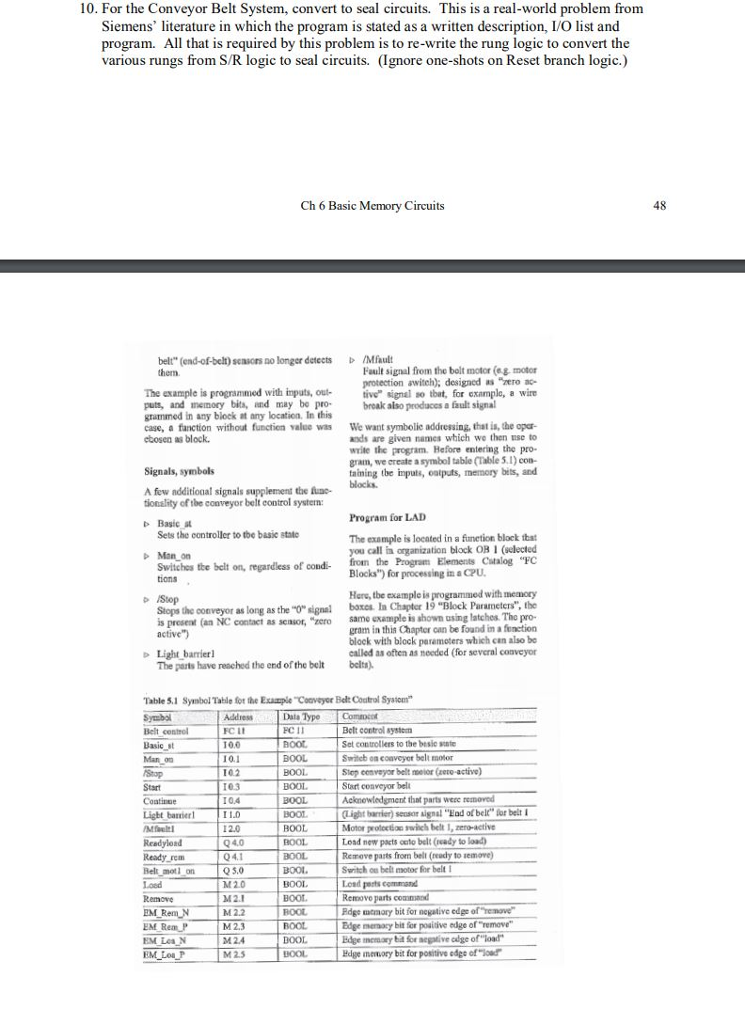

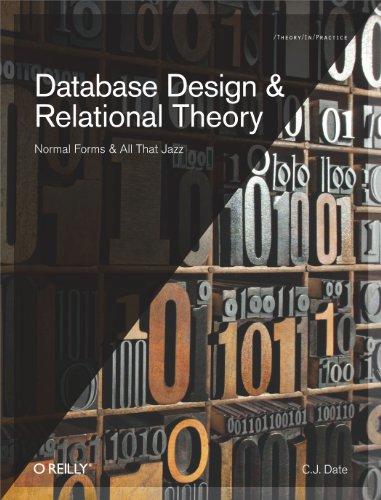

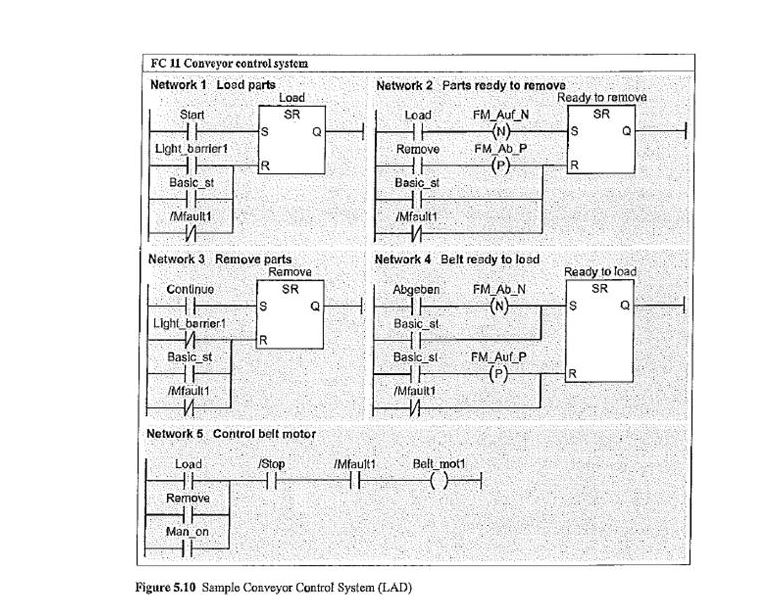

10. For the Conveyor Belt System, convert to seal circuits. This is a real-world problem from Siemens' terature in which the program is stated as a written description, L/O list and program. All that is required by this problem is to re-write the rung logic to convert the various rungs from S/R logic to seal circuits. (Ignore one-shots on Reset branch logic.) Ch 6 Basic Memory Circuits 4 belt (end-of-belt) scasors no longer detects /Mfault Fault signal from the bolt motor (g. motor protection awitch); desigaed as "zero ac- The example is programmed with inpats,utve signal so tbat, for cxamplo, a wire puts, and memory bits, and may be pro- grammed in any block at any location. In this break also prodaccs a fault signal case, a fanction without function value was We want symbolic addressing, that is, the opar- ands are given names which we then use to write the program. Hefore entering the pro- gram, we create a symbol table (Table 5.1) co- taining the imputs, oatputs, memory bits, and ebosen as block Signals, symbols A few ndditional signals supplement the fune- tionality of the conveyor belt control systerm: Program for LAD b Basic st Sets the controller to tbe basic staic The example is located in a funetion block that you call in organization block OB I (selected P Man on Switches the belt on, regardless of cond from the Program Elements Cutalog "FC Blocks") for processing imaCPU. Here, tbe example is programued with memory bata la Chapter 19-Block Parameters. Siops the coveyor as long as the-" signal zero same example is shown using latches.Tho pro- gram in this Chapter can be foand in a fenction block with block paramoters which cen also be called as often as needed (for several conveyor D Light barrierl The parts have resched the end of the belt be Table 5.1 Symbol Table fot the Example Conveyer Belt Coutrol Sysion Address FC I Dala TypeComco FC II Belt control system Set controllers to the besic sente Switeb on coaveyer belt motor Belt centeol Start conveyor bel 03 10.4 Light barnrILD Light barrier) seusor signal "ad of belc" for belt I 12.0 Losd new pacts onto belt (ready to loa Remove parts from bell (rxody to remove) Q4.0 Ready renm Belt motl on Suritch ou belt motofor beltI Lond pests command Renmove parts commnnd M20 M2.1 M2.2 M2.3 424 M 2.5 Rdge mamory bit for negative edge of remave Edge memacy bit fier positdive edge of "remove EMM ReaP EM Lea N EM Loa P t for egative cdge of load Edge memory bit for positive edge of "Yood" 10. For the Conveyor Belt System, convert to seal circuits. This is a real-world problem from Siemens' terature in which the program is stated as a written description, L/O list and program. All that is required by this problem is to re-write the rung logic to convert the various rungs from S/R logic to seal circuits. (Ignore one-shots on Reset branch logic.) Ch 6 Basic Memory Circuits 4 belt (end-of-belt) scasors no longer detects /Mfault Fault signal from the bolt motor (g. motor protection awitch); desigaed as "zero ac- The example is programmed with inpats,utve signal so tbat, for cxamplo, a wire puts, and memory bits, and may be pro- grammed in any block at any location. In this break also prodaccs a fault signal case, a fanction without function value was We want symbolic addressing, that is, the opar- ands are given names which we then use to write the program. Hefore entering the pro- gram, we create a symbol table (Table 5.1) co- taining the imputs, oatputs, memory bits, and ebosen as block Signals, symbols A few ndditional signals supplement the fune- tionality of the conveyor belt control systerm: Program for LAD b Basic st Sets the controller to tbe basic staic The example is located in a funetion block that you call in organization block OB I (selected P Man on Switches the belt on, regardless of cond from the Program Elements Cutalog "FC Blocks") for processing imaCPU. Here, tbe example is programued with memory bata la Chapter 19-Block Parameters. Siops the coveyor as long as the-" signal zero same example is shown using latches.Tho pro- gram in this Chapter can be foand in a fenction block with block paramoters which cen also be called as often as needed (for several conveyor D Light barrierl The parts have resched the end of the belt be Table 5.1 Symbol Table fot the Example Conveyer Belt Coutrol Sysion Address FC I Dala TypeComco FC II Belt control system Set controllers to the besic sente Switeb on coaveyer belt motor Belt centeol Start conveyor bel 03 10.4 Light barnrILD Light barrier) seusor signal "ad of belc" for belt I 12.0 Losd new pacts onto belt (ready to loa Remove parts from bell (rxody to remove) Q4.0 Ready renm Belt motl on Suritch ou belt motofor beltI Lond pests command Renmove parts commnnd M20 M2.1 M2.2 M2.3 424 M 2.5 Rdge mamory bit for negative edge of remave Edge memacy bit fier positdive edge of "remove EMM ReaP EM Lea N EM Loa P t for egative cdge of load Edge memory bit for positive edge of "Yood