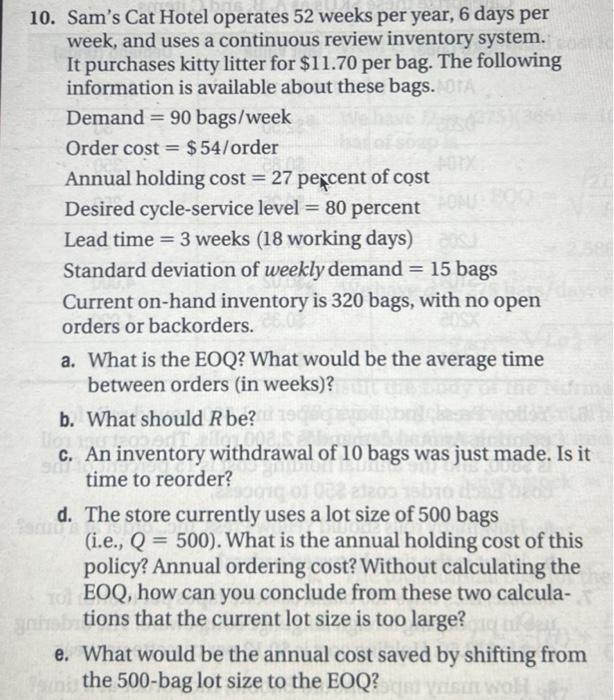

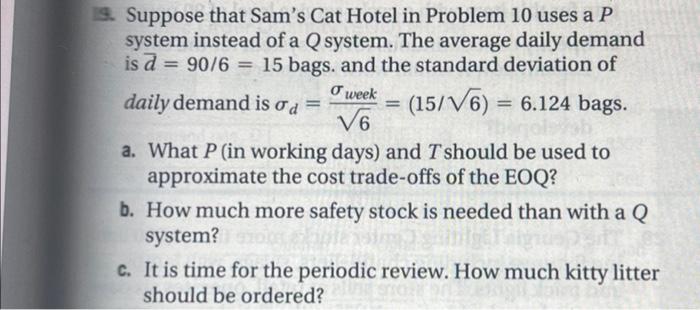

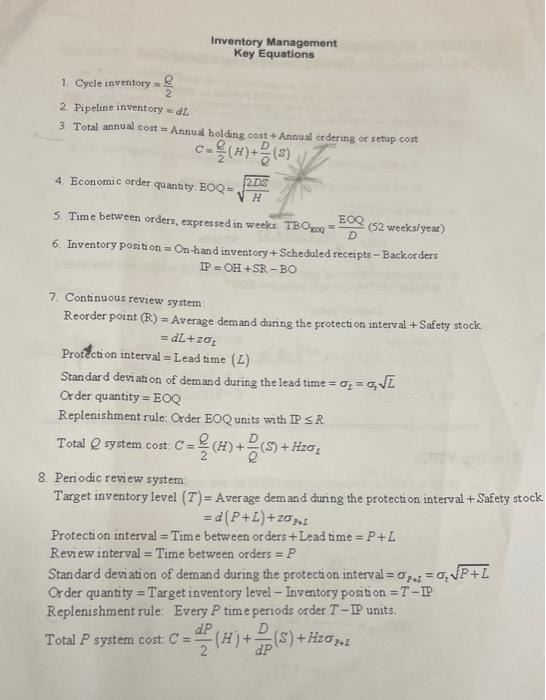

10. Sam's Cat Hotel operates 52 weeks per year, 6 days per week, and uses a continuous review inventory system. It purchases kitty litter for $11.70 per bag. The following information is available about these bags. Demand =90 bags / week Order cost =$54/ order Annual holding cost =27 pecent of cost Desired cycle-service level =80 percent Lead time =3 weeks ( 18 working days) Standard deviation of weekly demand =15 bags Current on-hand inventory is 320 bags, with no open orders or backorders. a. What is the EOQ? What would be the average time between orders (in weeks)? b. What should R be? c. An inventory withdrawal of 10 bags was just made. Is it time to reorder? d. The store currently uses a lot size of 500 bags (i.e., Q=500 ). What is the annual holding cost of this policy? Annual ordering cost? Without calculating the EOQ, how can you conclude from these two calculations that the current lot size is too large? e. What would be the annual cost saved by shifting from the 500 -bag lot size to the EOQ ? 19. Suppose that Sam's Cat Hotel in Problem 10 uses a P system instead of a Q system. The average daily demand is d=90/6=15 bags. and the standard deviation of daily demand is d=6week=(15/6)=6.124 bags. a. What P (in working days) and T should be used to approximate the cost trade-offs of the EOQ? b. How much more safety stock is needed than with a Q system? c. It is time for the periodic review. How much kitty litter should be ordered? 4. Economic order quantity: EOQ=H2DS 5. Time between orders, expressed in weeks: TBOsw0s=DEOQ (52 weeks/year) 6. Inventory position =On-hand inventory + Scheduled receipts - Backor ders IP=OH+SRBO 7. Continuous review system Reorder point (R)= Average demand duning the protection interval + Safety stock =dL+zt Protection interval = Lead time (L) Standard deviation of demand during the lead time =L=,L Order quantity =EOQ Replenishment rule: Order EOQ units with IPR Total Q system cost: C=2Q(H)+QD(S)+Hzt 8. Periodic review system Target inventory level (T)= Average demand during the protection interval + Safety sto =d(P+L)+zR+L Protection interval = Time between orders + Lead time =P+L Review interval = Time between orders =P Standard deviation of demand during the protection interval =P+I=2P+L Order quantity = Target inventory level - Inventory position =TP Replenishment rule: Every P time periods order TP units. Total P system cost: C=2dP(H)+dPD(S)+HzP+1