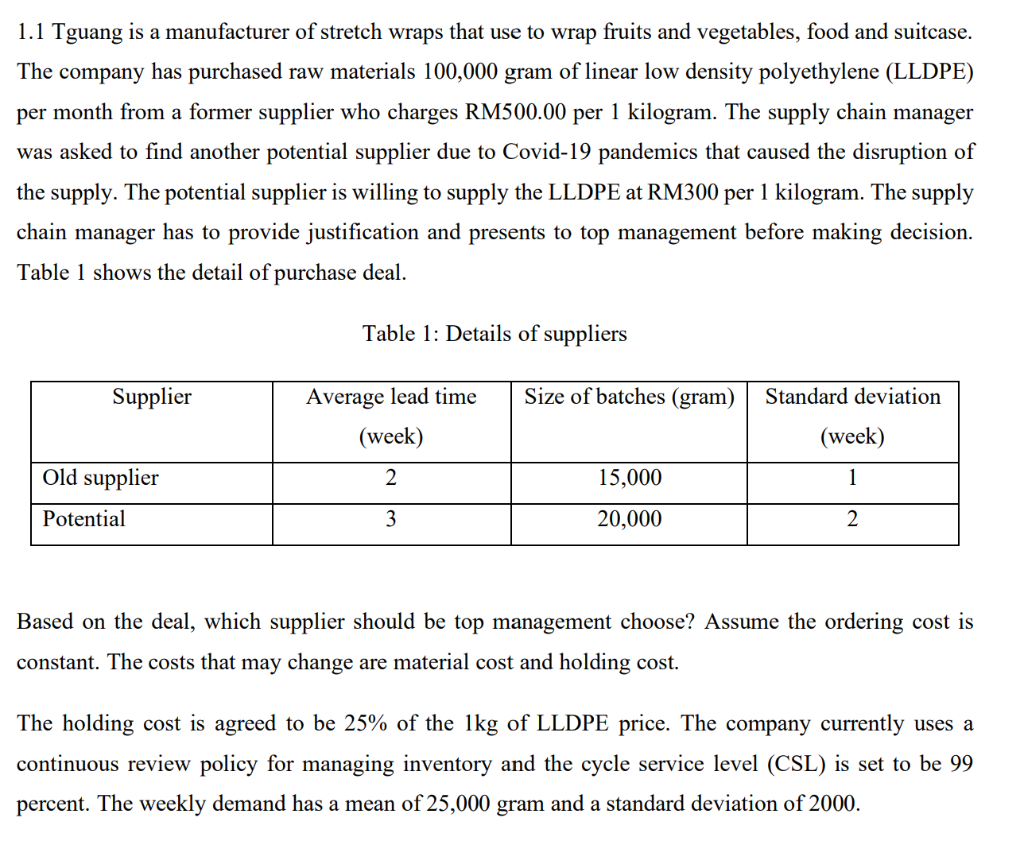

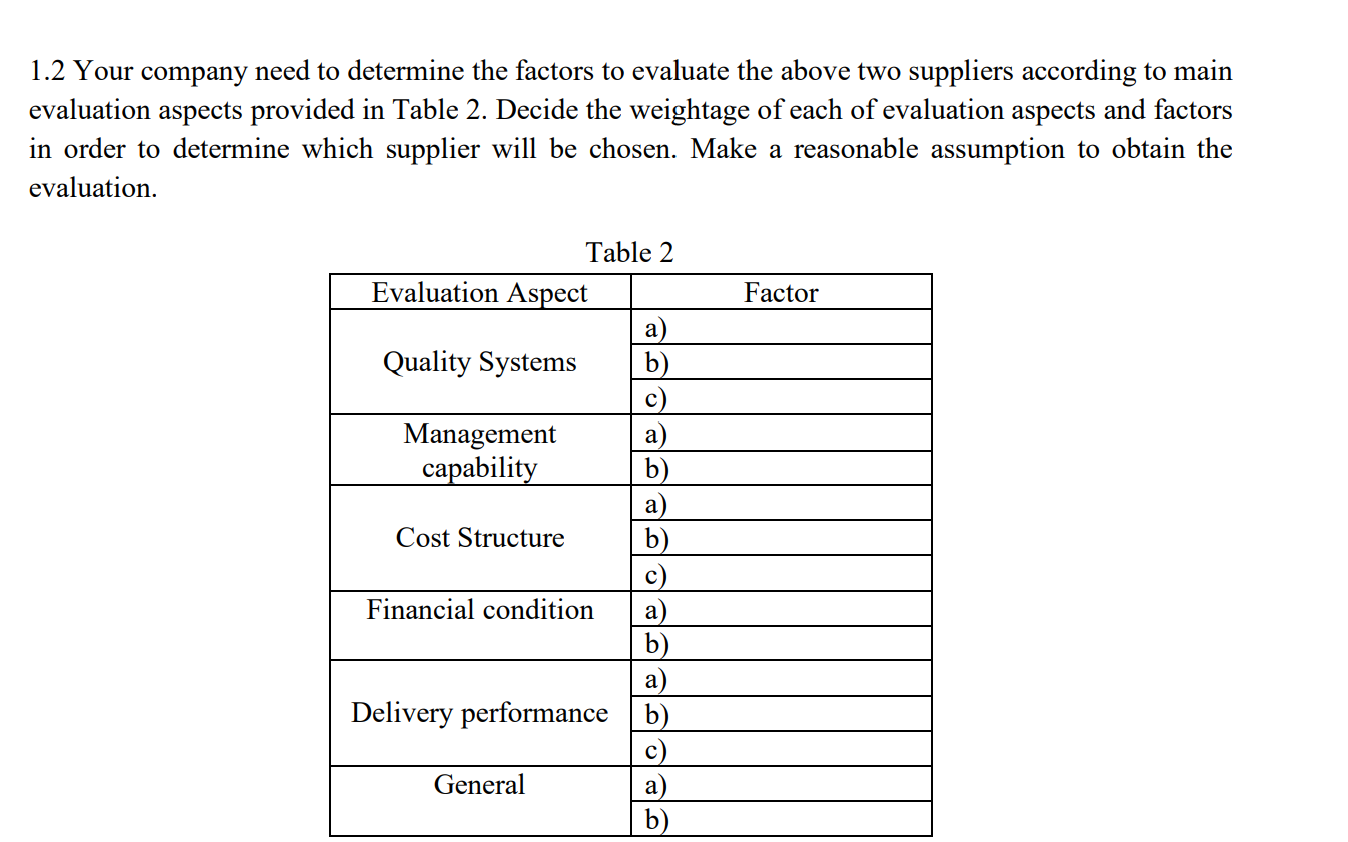

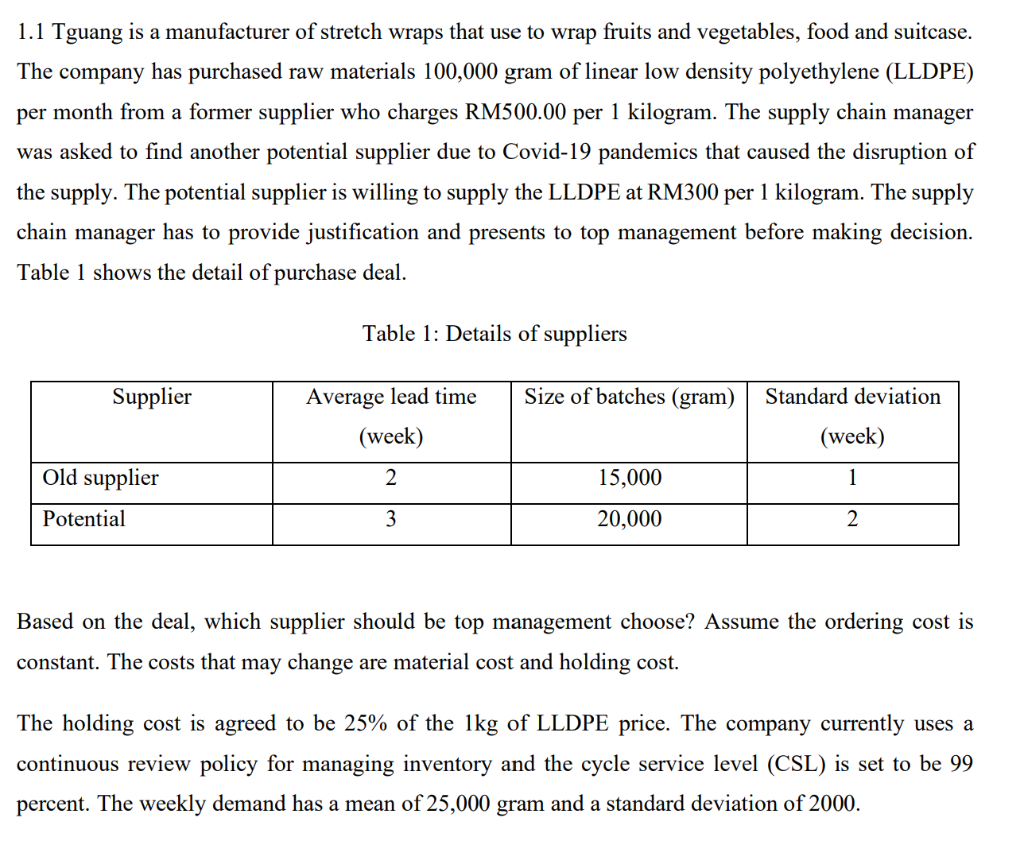

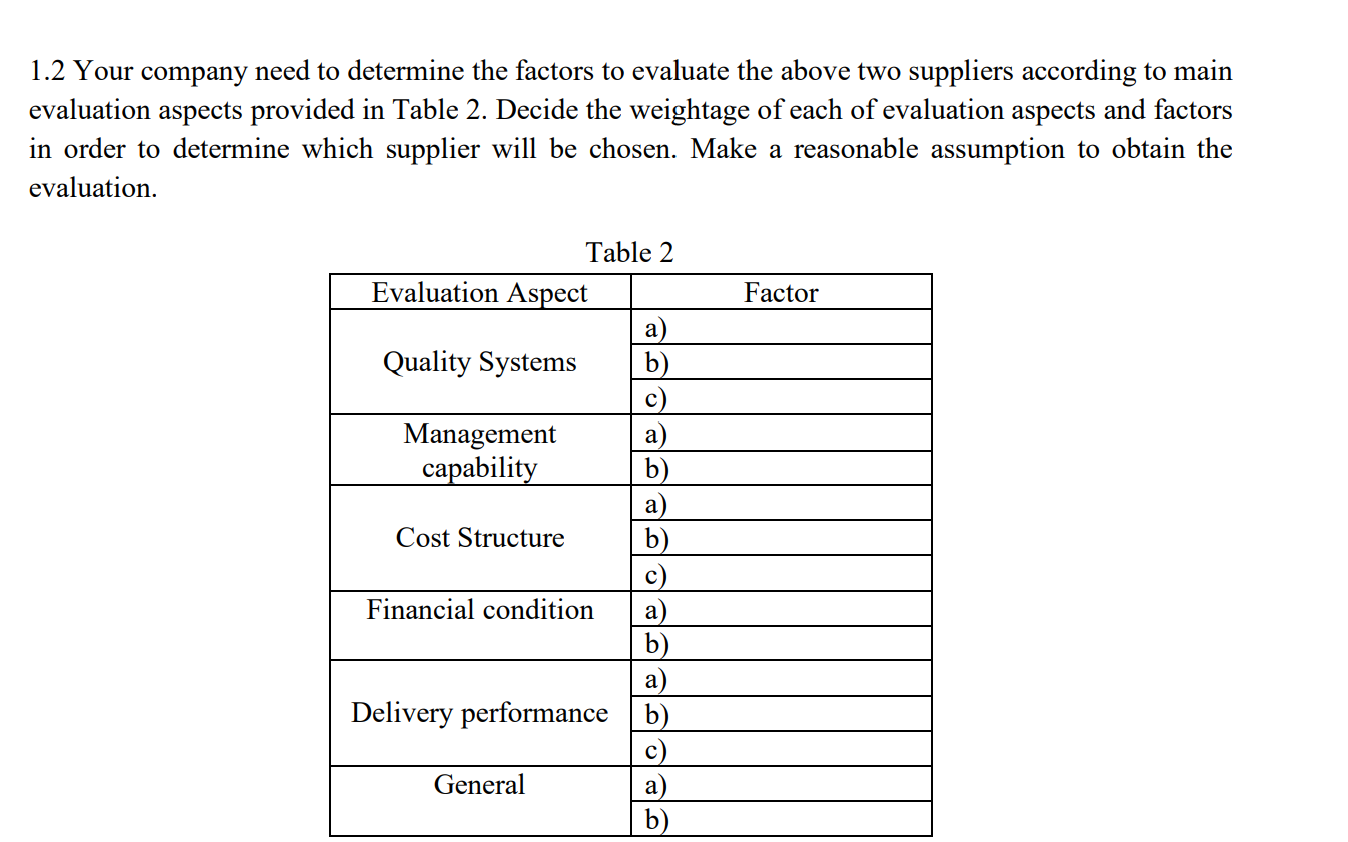

1.1 Tguang is a manufacturer of stretch wraps that use to wrap fruits and vegetables, food and suitcase. The company has purchased raw materials 100,000 gram of linear low density polyethylene (LLDPE) per month from a former supplier who charges RM500.00 per 1 kilogram. The supply chain manager was asked to find another potential supplier due to Covid-19 pandemics that caused the disruption of the supply. The potential supplier is willing to supply the LLDPE at RM300 per 1 kilogram. The supply chain manager has to provide justification and presents to top management before making decision. Table 1 shows the detail of purchase deal. Table 1: Details of suppliers Supplier Size of batches (gram) Standard deviation Average lead time (week) (week) Old supplier 2 15,000 1 Potential 3 20,000 2 Based on the deal, which supplier should be top management choose? Assume the ordering cost is constant. The costs that may change are material cost and holding cost. The holding cost is agreed to be 25% of the 1kg of LLDPE price. The company currently uses a continuous review policy for managing inventory and the cycle service level (CSL) is set to be 99 percent. The weekly demand has a mean of 25,000 gram and a standard deviation of 2000. 1.2 Your company need to determine the factors to evaluate the above two suppliers according to main evaluation aspects provided in Table 2. Decide the weightage of each of evaluation aspects and factors in order to determine which supplier will be chosen. Make a reasonable assumption to obtain the evaluation. Factor Table 2 Evaluation Aspect a) Quality Systems b) c) Management a) capability b) a) Cost Structure b) c) Financial condition a b) a) Delivery performance b) c) General a) 1.1 Tguang is a manufacturer of stretch wraps that use to wrap fruits and vegetables, food and suitcase. The company has purchased raw materials 100,000 gram of linear low density polyethylene (LLDPE) per month from a former supplier who charges RM500.00 per 1 kilogram. The supply chain manager was asked to find another potential supplier due to Covid-19 pandemics that caused the disruption of the supply. The potential supplier is willing to supply the LLDPE at RM300 per 1 kilogram. The supply chain manager has to provide justification and presents to top management before making decision. Table 1 shows the detail of purchase deal. Table 1: Details of suppliers Supplier Size of batches (gram) Standard deviation Average lead time (week) (week) Old supplier 2 15,000 1 Potential 3 20,000 2 Based on the deal, which supplier should be top management choose? Assume the ordering cost is constant. The costs that may change are material cost and holding cost. The holding cost is agreed to be 25% of the 1kg of LLDPE price. The company currently uses a continuous review policy for managing inventory and the cycle service level (CSL) is set to be 99 percent. The weekly demand has a mean of 25,000 gram and a standard deviation of 2000. 1.2 Your company need to determine the factors to evaluate the above two suppliers according to main evaluation aspects provided in Table 2. Decide the weightage of each of evaluation aspects and factors in order to determine which supplier will be chosen. Make a reasonable assumption to obtain the evaluation. Factor Table 2 Evaluation Aspect a) Quality Systems b) c) Management a) capability b) a) Cost Structure b) c) Financial condition a b) a) Delivery performance b) c) General a)