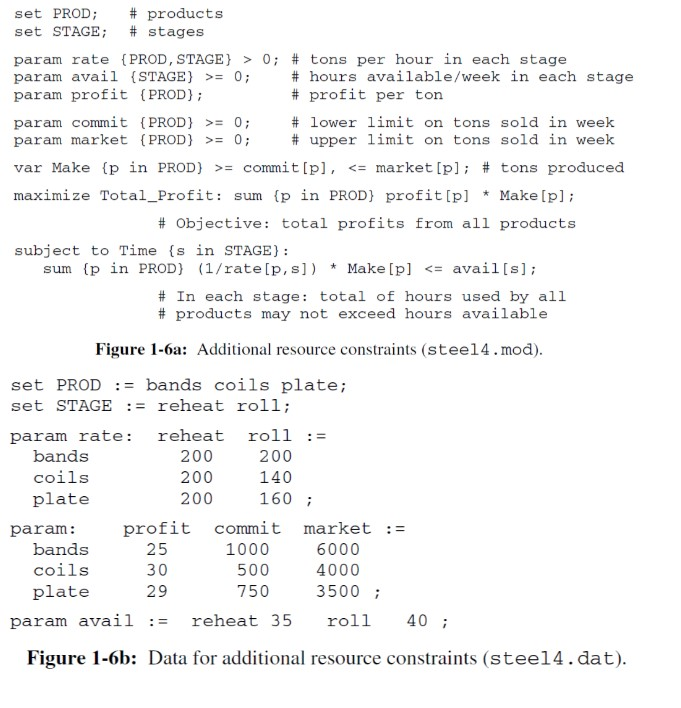

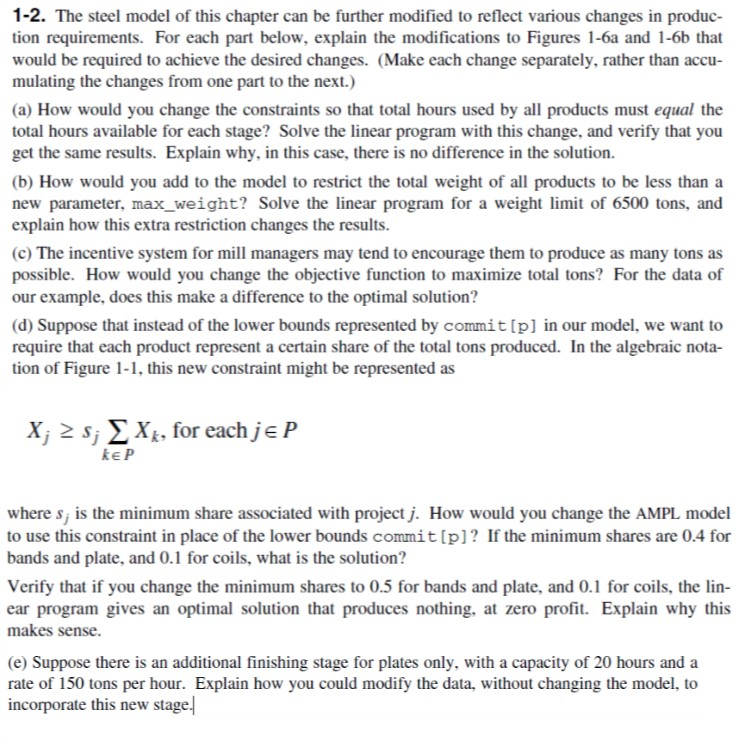

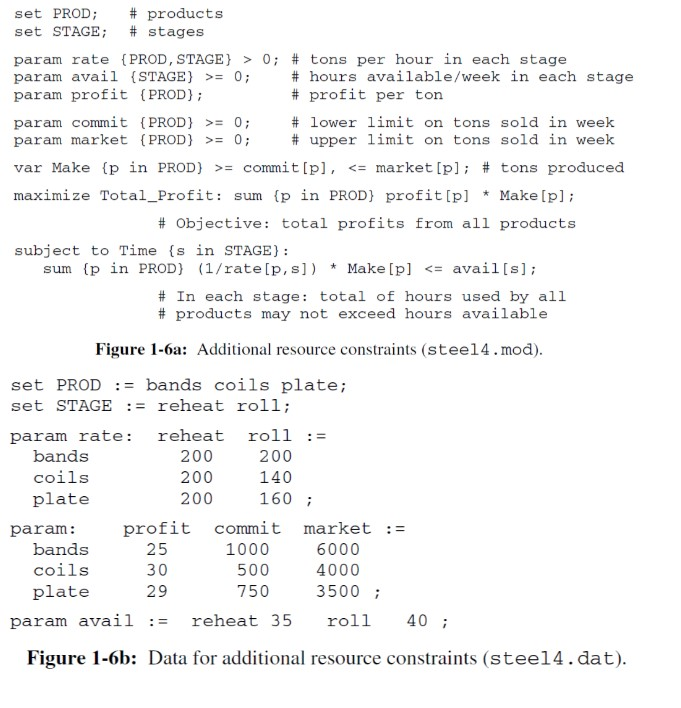

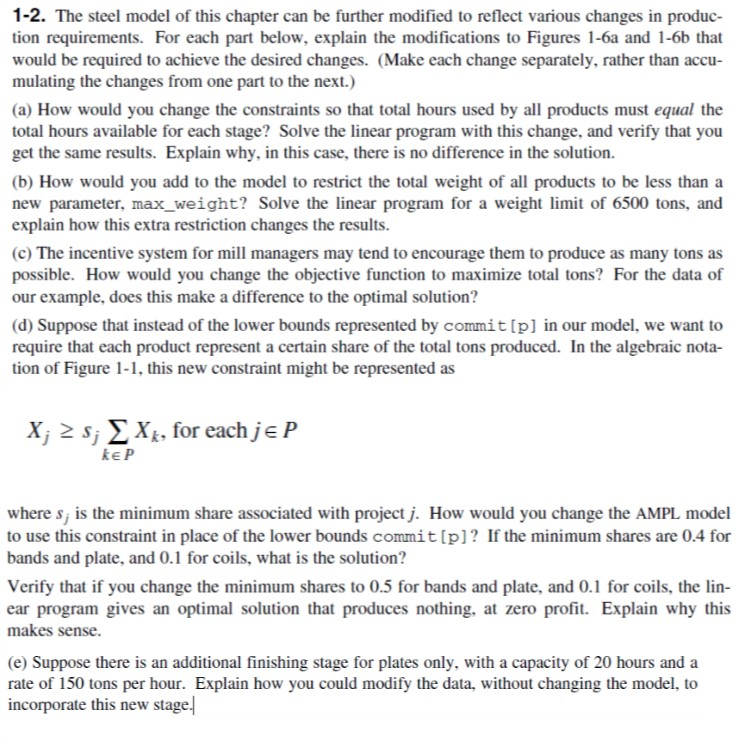

1-2The steel model of this chapter can be further modified to reflect various changes in produc- tion requirements. For each part below, explain the modifications to Figures 1-6a and 1-6b that would be required to achieve the desired changes. (Make each change separately, rather than accu mulating the changes from one part to the next.) (a) How would you change the constraints so that total hours used by all products must equal the total hours available for each stage? Solve the linear program with this change, and verify that you get the same results. Explain why, in this case, there is no difference in the solution. (b) How would you add to the model to restrict the total weight of all products to be less than a new parameter, max_weight? Solve the linear program for a weight limit of 6500 tons, and explain how this extra restriction changes the results. (c) The incentive system for mill managers may tend to encourage them to produce as many tons as possible. How would you change the objective function to maximize total tons? For the data of our example, does this make a difference to the optimal solution? (d) Suppose that instead of the lower bounds represented by commit[p] in our model, we want to require that each product represent a certain share of the total tons produced. In the algebraic nota- tion of Figure 1-1, this new constraint might be represented as where s, is the minimum share associated with project j. How would you change the AMPL model to use this constraint in place of the lower bounds commit [p]? If the minimum shares are 0.4 for bands and plate, and 0.1 for coils, what is the solution? Verify that if you change the minimum shares to 0.5 for bands and plate, and 0.1 for coils, the lin- ear program gives an optimal solution that produces nothing, at zero profit. Explain why this makes sense (e) Suppose there is an additional finishing stage for plates only, with a capacity of 20 hours and a rate of 150 tons per hour. Explain how you could modify the data, without changing the model, to incorporate this new stage 1-2The steel model of this chapter can be further modified to reflect various changes in produc- tion requirements. For each part below, explain the modifications to Figures 1-6a and 1-6b that would be required to achieve the desired changes. (Make each change separately, rather than accu mulating the changes from one part to the next.) (a) How would you change the constraints so that total hours used by all products must equal the total hours available for each stage? Solve the linear program with this change, and verify that you get the same results. Explain why, in this case, there is no difference in the solution. (b) How would you add to the model to restrict the total weight of all products to be less than a new parameter, max_weight? Solve the linear program for a weight limit of 6500 tons, and explain how this extra restriction changes the results. (c) The incentive system for mill managers may tend to encourage them to produce as many tons as possible. How would you change the objective function to maximize total tons? For the data of our example, does this make a difference to the optimal solution? (d) Suppose that instead of the lower bounds represented by commit[p] in our model, we want to require that each product represent a certain share of the total tons produced. In the algebraic nota- tion of Figure 1-1, this new constraint might be represented as where s, is the minimum share associated with project j. How would you change the AMPL model to use this constraint in place of the lower bounds commit [p]? If the minimum shares are 0.4 for bands and plate, and 0.1 for coils, what is the solution? Verify that if you change the minimum shares to 0.5 for bands and plate, and 0.1 for coils, the lin- ear program gives an optimal solution that produces nothing, at zero profit. Explain why this makes sense (e) Suppose there is an additional finishing stage for plates only, with a capacity of 20 hours and a rate of 150 tons per hour. Explain how you could modify the data, without changing the model, to incorporate this new stage