Answered step by step

Verified Expert Solution

Question

1 Approved Answer

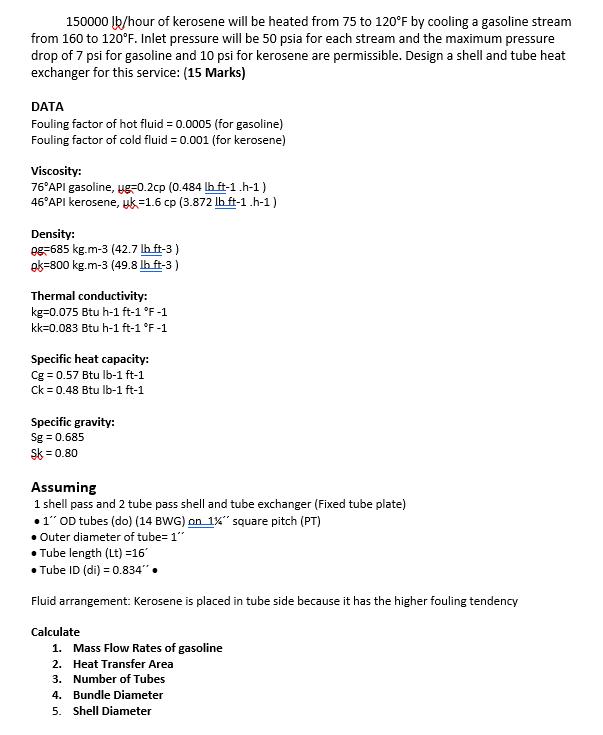

150000 lb/hour of kerosene will be heated from 75 to 120F by cooling a gasoline stream from 160 to 120F. Inlet pressure will be

150000 lb/hour of kerosene will be heated from 75 to 120F by cooling a gasoline stream from 160 to 120F. Inlet pressure will be 50 psia for each stream and the maximum pressure drop of 7 psi for gasoline and 10 psi for kerosene are permissible. Design a shell and tube heat exchanger for this service: (15 Marks) DATA Fouling factor of hot fluid = 0.0005 (for gasoline) Fouling factor of cold fluid = 0.001 (for kerosene) Viscosity: 76API gasoline, ug-0.2cp (0.484 lb ft-1.h-1) 46API kerosene, uk=1.6 cp (3.872 lb ft-1.h-1) Density: og 685 kg.m-3 (42.7 lb ft-3) ek-800 kg.m-3 (49.8 lb ft-3) Thermal conductivity: kg=0.075 Btu h-1 ft-1 F -1 kk-0.083 Btu h-1 ft-1 F-1 Specific heat capacity: Cg = 0.57 Btu lb-1 ft-1 Ck = 0.48 Btu lb-1 ft-1 Specific gravity: Sg=0.68 Sk = 0.80 Assuming 1 shell pass and 2 tube pass shell and tube exchanger (Fixed tube plate) 1" OD tubes (do) (14 BWG) on 1%" square pitch (PT) Outer diameter of tube=1" Tube length (Lt)=16' Tube ID (di) = 0.834". Fluid arrangement: Kerosene is placed in tube side because it has the higher fouling tendency Calculate 1. Mass Flow Rates of gasoline 2. Heat Transfer Area 3. Number of Tubes 4. Bundle Diameter 5. Shell Diameter

Step by Step Solution

★★★★★

3.38 Rating (151 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started