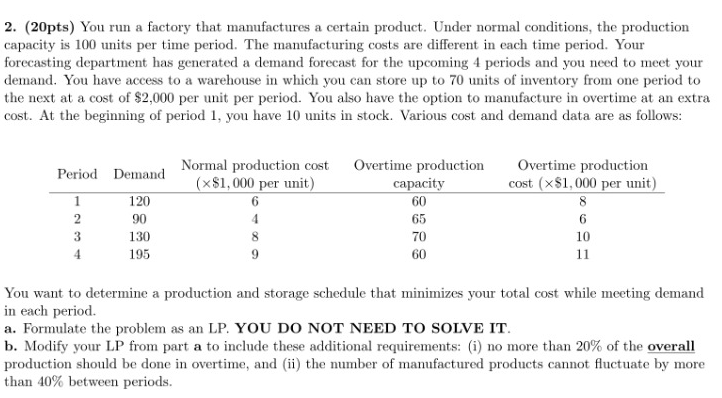

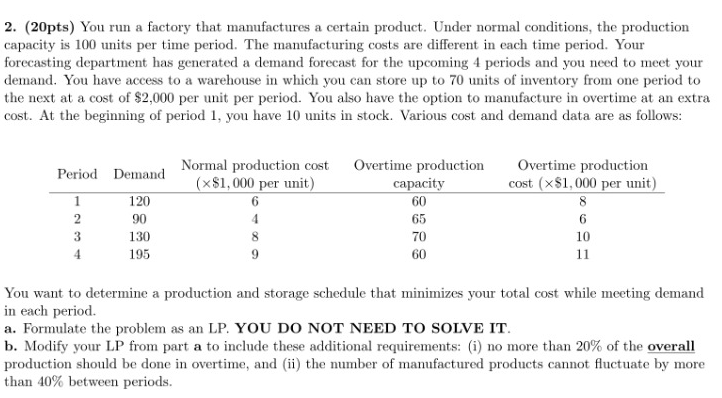

2. (20pts) You run a factory that manufactures a certain product. Under normal conditions, the production capacity is 100 units per time period. The manufacturing costs are different in each time period. Your forecasting department has generated a demand forecast for the upcoming 4 periods and you need to meet your demand. You have access to a warehouse in which you can store up to 70 units of inventory from one period to the next at a cost of $2,000 per unit per period. You also have the option to manufacture in overtime at an extra cost. At the beginning of period 1, you have 10 units in stock. Various cost and demand data are as follows: Period Demand 1 2 3 4 120 90 130 195 Normal production cost Overtime production ($1,000 per unit) capacity 6 60 4 65 70 9 60 Overtime production cost ($1,000 per unit) 8 6 10 11 8 You want to determine a production and storage schedule that minimizes your total cost while meeting demand in each period. a. Formulate the problem as an LP. YOU DO NOT NEED TO SOLVE IT. b. Modify your LP from part a to include these additional requirements: (i) no more than 20% of the overall production should be done in overtime, and (ii) the number of manufactured products cannot fluctuate by more than 40% between periods. 2. (20pts) You run a factory that manufactures a certain product. Under normal conditions, the production capacity is 100 units per time period. The manufacturing costs are different in each time period. Your forecasting department has generated a demand forecast for the upcoming 4 periods and you need to meet your demand. You have access to a warehouse in which you can store up to 70 units of inventory from one period to the next at a cost of $2,000 per unit per period. You also have the option to manufacture in overtime at an extra cost. At the beginning of period 1, you have 10 units in stock. Various cost and demand data are as follows: Period Demand 1 2 3 4 120 90 130 195 Normal production cost Overtime production ($1,000 per unit) capacity 6 60 4 65 70 9 60 Overtime production cost ($1,000 per unit) 8 6 10 11 8 You want to determine a production and storage schedule that minimizes your total cost while meeting demand in each period. a. Formulate the problem as an LP. YOU DO NOT NEED TO SOLVE IT. b. Modify your LP from part a to include these additional requirements: (i) no more than 20% of the overall production should be done in overtime, and (ii) the number of manufactured products cannot fluctuate by more than 40% between periods