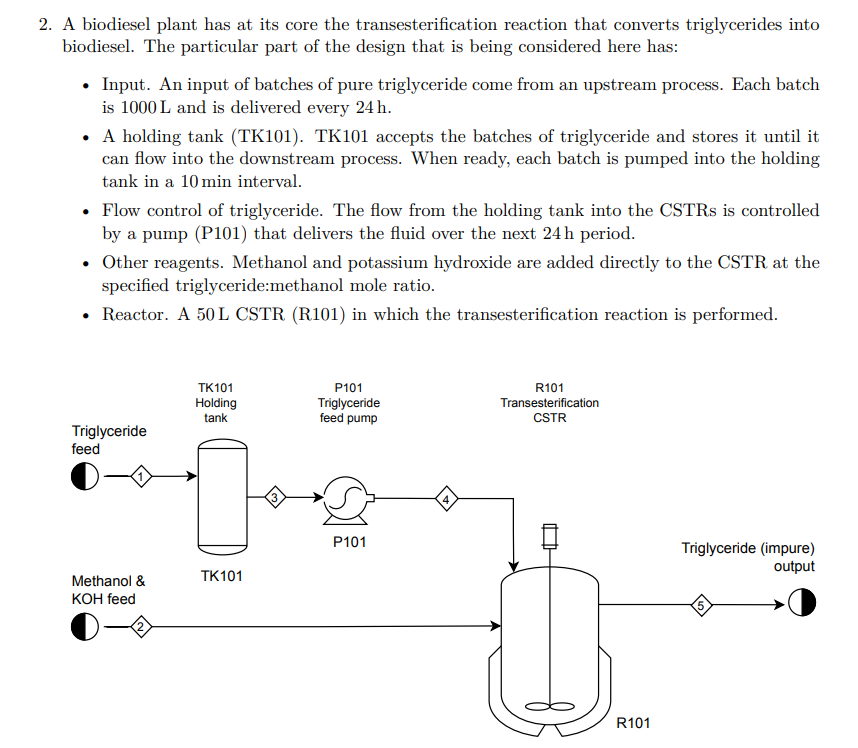

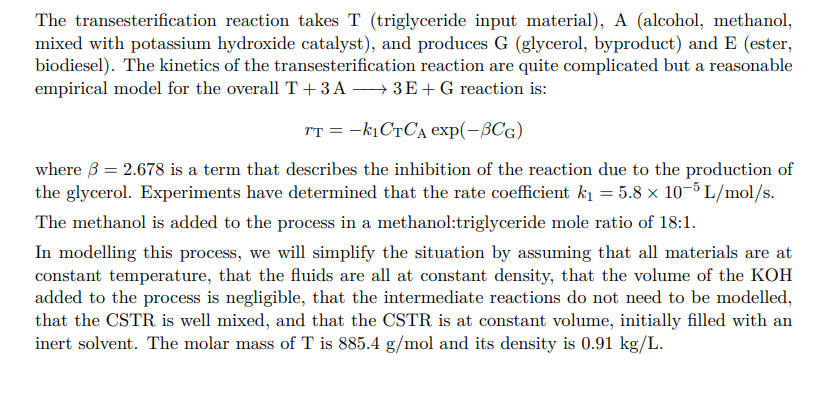

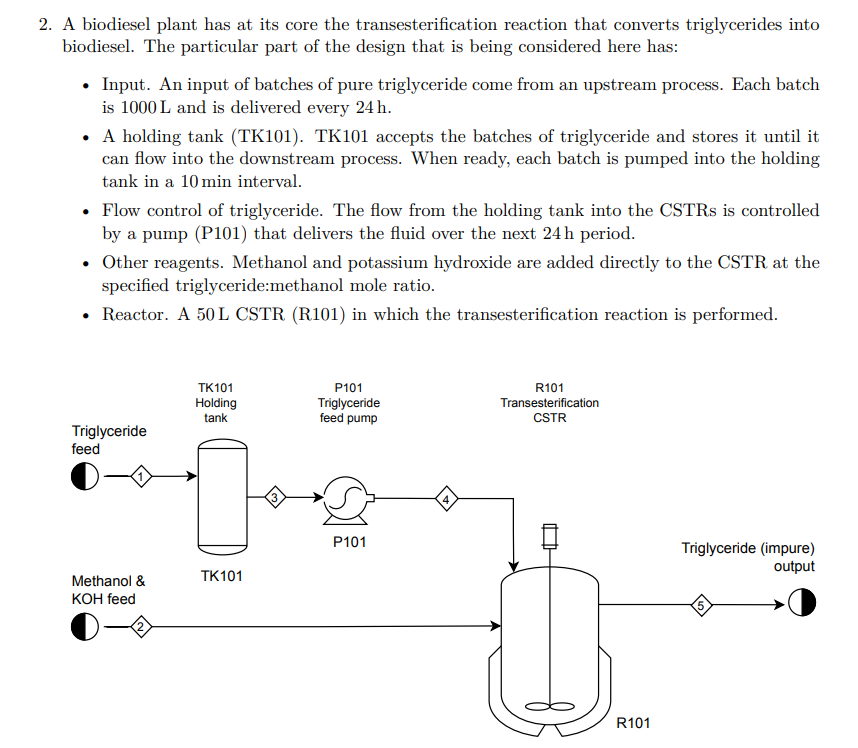

2. A biodiesel plant has at its core the transesterification reaction that converts triglycerides into biodiesel. The particular part of the design that is being considered here has: Input. An input of batches of pure triglyceride come from an upstream process. Each batch is 1000 L and is delivered every 24 h. A holding tank (TK101). TK101 accepts the batches of triglyceride and stores it until it can flow into the downstream process. When ready, each batch is pumped into the holding tank in a 10 min interval. Flow control of triglyceride. The flow from the holding tank into the CSTRs is controlled by a pump (P101) that delivers the fluid over the next 24 h period. Other reagents. Methanol and potassium hydroxide are added directly to the CSTR at the specified triglyceride:methanol mole ratio. Reactor. A 50L CSTR (R101) in which the transesterification reaction is performed. TK101 Holding tank P101 Triglyceride feed pump R101 Transesterification CSTR Triglyceride feed P101 Triglyceride (impure) output TK101 Methanol & KOH feed 5 R101 The transesterification reaction takes T (triglyceride input material), A (alcohol, methanol, mixed with potassium hydroxide catalyst), and produces G (glycerol, byproduct) and E (ester, biodiesel). The kinetics of the transesterification reaction are quite complicated but a reasonable empirical model for the overall T +3A +3E+G reaction is: IT = -kiCTCA exp(-BCG) where = 2.678 is a term that describes the inhibition of the reaction due to the production of the glycerol. Experiments have determined that the rate coefficient ki = 5.8 x 10-5 L/mol/s. The methanol is added to the process in a methanol:triglyceride mole ratio of 18:1. In modelling this process, we will simplify the situation by assuming that all materials are at constant temperature, that the fluids are all at constant density, that the volume of the KOH added to the process is negligible, that the intermediate reactions do not need to be modelled, that the CSTR is well mixed, and that the CSTR is at constant volume, initially filled with an inert solvent. The molar mass of T is 885.4 g/mol and its density is 0.91 kg/L. (a) Starting with the material balance for the process, develop a process model for the holding tank and CSTR. A suitable state vector for the model is (Vo, C15, CG5, CA5, CE5 where V, is the liquid volume in the holding tank and the subscript 5 is denoting stream 5, which corresponds to the conditions inside the CSTR. (b) Make plots of how the process is predicted to behave over the first 48 h period including: the volume in the holding tank, the concentration of unreacted triglyceride in the output, and the concentration of biodiesel in the output. Estimate the conversion from the process. (c) The output of the process in the first 24 h is very different to the next 24 h. Briefly describe why this is. An alternative design would not use a pump to move the triglyceride from the holding tank to the CSTR, but instead allow it to be gravity fed. The volumetric flow rate from the holding tank would then be given by vout ve where k, = 0.0050 dm's-1 is an orifice coefficient and a = 80 dm is the cross-sectional area of the holding tank. The feed ratio of methanol to triglyceride is still maintained at 18:1. kol (d) Update your model to include the gravity feed from the holding tank and make plots to show the behaviour of the process over 7 days. (e) Discuss the new features that using a gravity feed from the holding tank brings into the process behaviour. Thinking about the process as a whole, briefly outline what other changes might be necessary. (f) The orifice coefficient, ko, can be varied by opening or closing a valve on the tank outlet. Make plots for the volume of liquid in the holding tank and the biodiesel output concentra- tion for a range of ko values and discuss how this parameter should be tuned for optimal operation of the process. 2. A biodiesel plant has at its core the transesterification reaction that converts triglycerides into biodiesel. The particular part of the design that is being considered here has: Input. An input of batches of pure triglyceride come from an upstream process. Each batch is 1000 L and is delivered every 24 h. A holding tank (TK101). TK101 accepts the batches of triglyceride and stores it until it can flow into the downstream process. When ready, each batch is pumped into the holding tank in a 10 min interval. Flow control of triglyceride. The flow from the holding tank into the CSTRs is controlled by a pump (P101) that delivers the fluid over the next 24 h period. Other reagents. Methanol and potassium hydroxide are added directly to the CSTR at the specified triglyceride:methanol mole ratio. Reactor. A 50L CSTR (R101) in which the transesterification reaction is performed. TK101 Holding tank P101 Triglyceride feed pump R101 Transesterification CSTR Triglyceride feed P101 Triglyceride (impure) output TK101 Methanol & KOH feed 5 R101 The transesterification reaction takes T (triglyceride input material), A (alcohol, methanol, mixed with potassium hydroxide catalyst), and produces G (glycerol, byproduct) and E (ester, biodiesel). The kinetics of the transesterification reaction are quite complicated but a reasonable empirical model for the overall T +3A +3E+G reaction is: IT = -kiCTCA exp(-BCG) where = 2.678 is a term that describes the inhibition of the reaction due to the production of the glycerol. Experiments have determined that the rate coefficient ki = 5.8 x 10-5 L/mol/s. The methanol is added to the process in a methanol:triglyceride mole ratio of 18:1. In modelling this process, we will simplify the situation by assuming that all materials are at constant temperature, that the fluids are all at constant density, that the volume of the KOH added to the process is negligible, that the intermediate reactions do not need to be modelled, that the CSTR is well mixed, and that the CSTR is at constant volume, initially filled with an inert solvent. The molar mass of T is 885.4 g/mol and its density is 0.91 kg/L. (a) Starting with the material balance for the process, develop a process model for the holding tank and CSTR. A suitable state vector for the model is (Vo, C15, CG5, CA5, CE5 where V, is the liquid volume in the holding tank and the subscript 5 is denoting stream 5, which corresponds to the conditions inside the CSTR. (b) Make plots of how the process is predicted to behave over the first 48 h period including: the volume in the holding tank, the concentration of unreacted triglyceride in the output, and the concentration of biodiesel in the output. Estimate the conversion from the process. (c) The output of the process in the first 24 h is very different to the next 24 h. Briefly describe why this is. An alternative design would not use a pump to move the triglyceride from the holding tank to the CSTR, but instead allow it to be gravity fed. The volumetric flow rate from the holding tank would then be given by vout ve where k, = 0.0050 dm's-1 is an orifice coefficient and a = 80 dm is the cross-sectional area of the holding tank. The feed ratio of methanol to triglyceride is still maintained at 18:1. kol (d) Update your model to include the gravity feed from the holding tank and make plots to show the behaviour of the process over 7 days. (e) Discuss the new features that using a gravity feed from the holding tank brings into the process behaviour. Thinking about the process as a whole, briefly outline what other changes might be necessary. (f) The orifice coefficient, ko, can be varied by opening or closing a valve on the tank outlet. Make plots for the volume of liquid in the holding tank and the biodiesel output concentra- tion for a range of ko values and discuss how this parameter should be tuned for optimal operation of the process