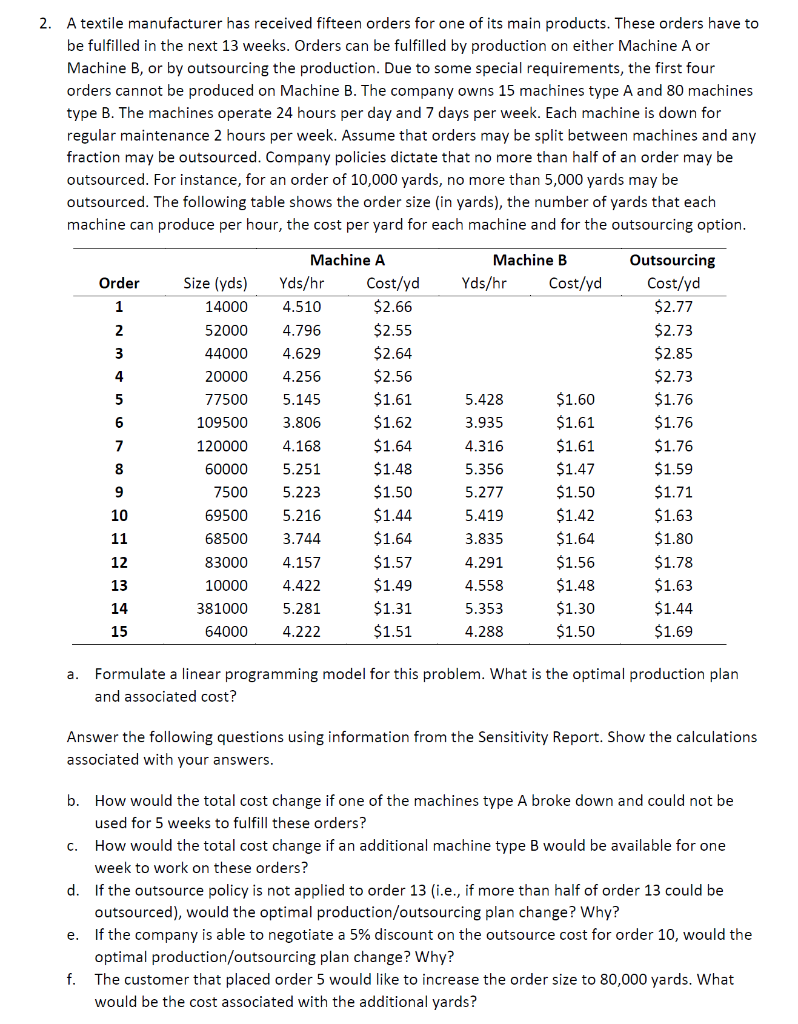

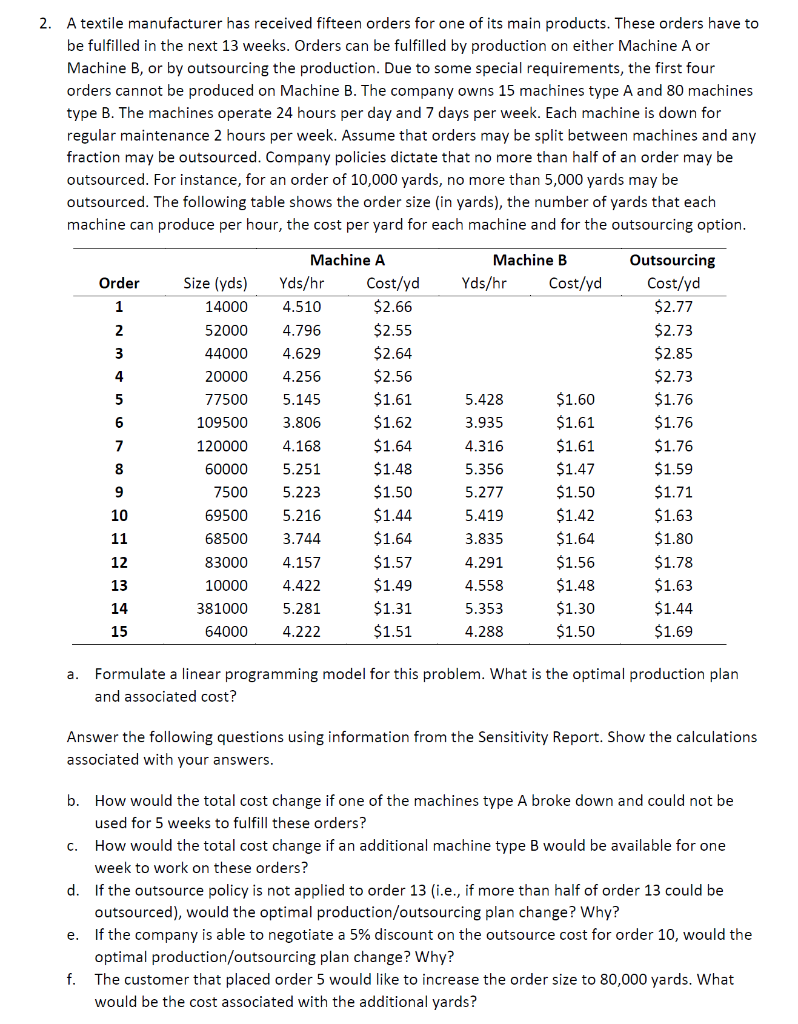

2. A textile manufacturer has received fifteen orders for one of its main products. These orders have to be fulfilled in the next 13 weeks. Orders can be fulfilled by production on either Machine A or Machine B, or by outsourcing the production. Due to some special requirements, the first four orders cannot be produced on Machine B. The company owns 15 machines type A and 80 machines type B. The machines operate 24 hours per day and 7 days per week. Each machine is down for regular maintenance 2 hours per week. Assume that orders may be split between machines and any fraction may be outsourced. Company policies dictate that no more than half of an order may be outsourced. For instance, for an order of 10,000 yards, no more than 5,000 yards may be outsourced. The following table shows the order size (in yards), the number of yards that each machine can produce per hour, the cost per yard for each machine and for the outsourcing option. Order Machine B Yds/hr Cost/yd Size (yds) 14000 52000 44000 20000 77500 109500 120000 60000 7500 69500 68500 83000 10000 381000 64000 Machine A Yds/hr Cost/yd 4.510 $2.66 4.796 $2.55 4.629 $2.64 4.256 $2.56 5.145 $1.61 3.806 $1.62 4.168 $1.64 5.251 $1.48 5.223 $1.50 5.216 $1.44 3.744 $1.64 4.157 $1.57 4.422 $1.49 5.281 $1.31 4.222 $1.51 5.428 3.935 4.316 5.356 5.277 5.419 3.835 4.291 4.558 5.353 4.288 $1.60 $1.61 $1.61 $1.47 $1.50 $1.42 $1.64 $1.56 $1.48 $1.30 $1.50 Outsourcing Cost/yd $2.77 $2.73 $2.85 $2.73 $1.76 $1.76 $1.76 $1.59 $1.71 $1.63 $1.80 $1.78 $1.63 $1.44 $1.69 a. Formulate a linear programming model for this problem. What is the optimal production plan and associated cost? Answer the following questions using information from the Sensitivity Report. Show the calculations associated with your answers. b. How would the total cost change if one of the machines type A broke down and could not be used for 5 weeks to fulfill these orders? C. How would the total cost change if an additional machine type B would be available for one week to work on these orders? d. If the outsource policy is not applied to order 13 (i.e., if more than half of order 13 could be outsourced), would the optimal production/outsourcing plan change? Why? e. If the company is able to negotiate a 5% discount on the outsource cost for order 10, would the optimal production/outsourcing plan change? Why? f. The customer that placed order 5 would like to increase the order size to 80,000 yards. What would be the cost associated with the additional yards? 2. A textile manufacturer has received fifteen orders for one of its main products. These orders have to be fulfilled in the next 13 weeks. Orders can be fulfilled by production on either Machine A or Machine B, or by outsourcing the production. Due to some special requirements, the first four orders cannot be produced on Machine B. The company owns 15 machines type A and 80 machines type B. The machines operate 24 hours per day and 7 days per week. Each machine is down for regular maintenance 2 hours per week. Assume that orders may be split between machines and any fraction may be outsourced. Company policies dictate that no more than half of an order may be outsourced. For instance, for an order of 10,000 yards, no more than 5,000 yards may be outsourced. The following table shows the order size (in yards), the number of yards that each machine can produce per hour, the cost per yard for each machine and for the outsourcing option. Order Machine B Yds/hr Cost/yd Size (yds) 14000 52000 44000 20000 77500 109500 120000 60000 7500 69500 68500 83000 10000 381000 64000 Machine A Yds/hr Cost/yd 4.510 $2.66 4.796 $2.55 4.629 $2.64 4.256 $2.56 5.145 $1.61 3.806 $1.62 4.168 $1.64 5.251 $1.48 5.223 $1.50 5.216 $1.44 3.744 $1.64 4.157 $1.57 4.422 $1.49 5.281 $1.31 4.222 $1.51 5.428 3.935 4.316 5.356 5.277 5.419 3.835 4.291 4.558 5.353 4.288 $1.60 $1.61 $1.61 $1.47 $1.50 $1.42 $1.64 $1.56 $1.48 $1.30 $1.50 Outsourcing Cost/yd $2.77 $2.73 $2.85 $2.73 $1.76 $1.76 $1.76 $1.59 $1.71 $1.63 $1.80 $1.78 $1.63 $1.44 $1.69 a. Formulate a linear programming model for this problem. What is the optimal production plan and associated cost? Answer the following questions using information from the Sensitivity Report. Show the calculations associated with your answers. b. How would the total cost change if one of the machines type A broke down and could not be used for 5 weeks to fulfill these orders? C. How would the total cost change if an additional machine type B would be available for one week to work on these orders? d. If the outsource policy is not applied to order 13 (i.e., if more than half of order 13 could be outsourced), would the optimal production/outsourcing plan change? Why? e. If the company is able to negotiate a 5% discount on the outsource cost for order 10, would the optimal production/outsourcing plan change? Why? f. The customer that placed order 5 would like to increase the order size to 80,000 yards. What would be the cost associated with the additional yards