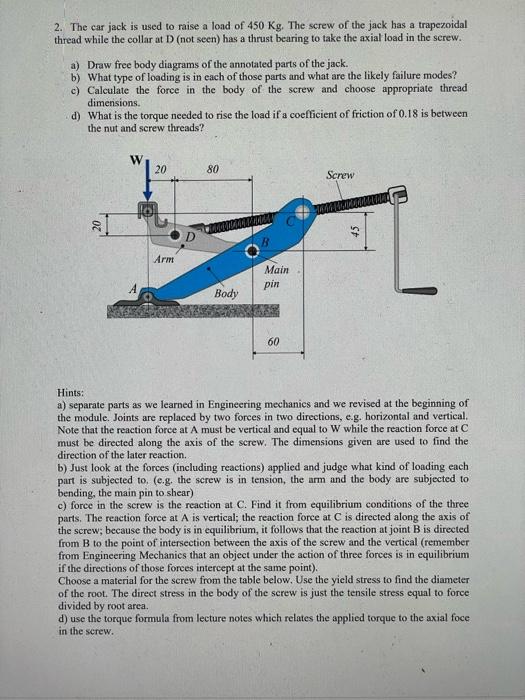

2. The car jack is used to raise a load of 450Kg. The screw of the jack has a trapezoidal thread while the collar at D (not seen) has a thrust bearing to take the axial load in the serew. a) Draw free body diagrams of the annotated parts of the jack. b) What type of loading is in each of those parts and what are the likely failure modes? c) Calculate the force in the body of the screw and choose appropriate thread dimensions. d) What is the torque needed to rise the load if a coefficient of friction of 0.18 is between the nut and screw threads? Hints: a) separate parts as we learned in Engineering mechanics and we revised at the beginning of the module. Joints are replaced by two forces in two directions, e.g. horizontal and vertical. Note that the reaction force at A must be vertical and equal to W while the reaction force at C must be directed along the axis of the screw. The dimensions given are used to find the direction of the later reaction. b) Just look at the forces (including reactions) applied and judge what kind of loading each part is subjected to, (e.g, the screw is in tension, the arm and the body are subjected to bending, the main pin to shear) c) force in the serew is the reaction at C. Find it from equilibrium conditions of the three parts. The reaction force at A is vertical; the reaction foree at C is directed along the axis of the screw; because the body is in equilibrium, it follows that the reaction at joint B is directed from B to the point of intersection between the axis of the screw and the vertical (remember from Engineering Mechanies that an object under the action of three forces is in equilibrium if the directions of those forees intercept at the same point). Choose a material for the screw from the table below, Use the yield stress to find the diameter of the root. The direct stress in the body of the screw is just the tensile stress equal to force divided by root area. d) use the torque formula from lecture notes which relates the applied torque to the axial foce in the screw