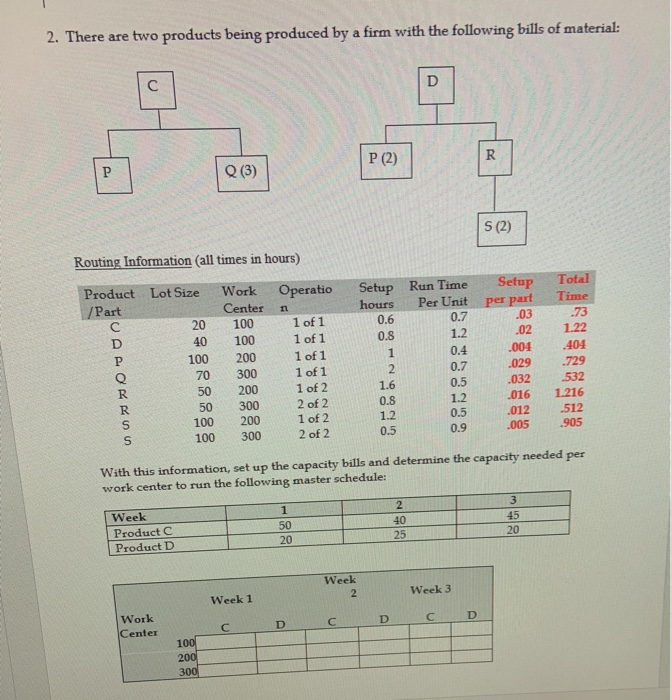

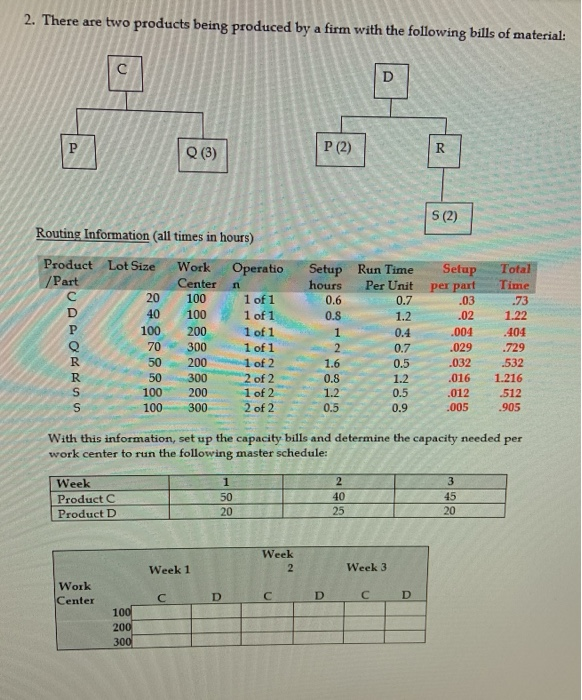

2. There are two products being produced by a firm with the following bills of material: D P (2) R Q(3) 5 (2) Routing Information (all times in hours) Operatio Setup per part n .03 Product Lot Size /Part 20 40 100 70 50 50 100 100 SUAAO Work Center 100 100 200 300 200 300 200 300 1 of 1 1 of 1 1 of 1 1 of 1 1 of 2 2 of 2 1 of 2 2 of 2 Setup Run Time hours Per Unit 0.6 0.7 0.8 1.2 1 0.4 2 0.7 1.6 0.8 1.2. 1.2 0.5 0.5 0.9 Total Time .73 1.22 .404 .729 -532 1.216 -512 .905 .02 .004 .029 .032 .016 .012 .005 0.5 With this information, set up the capacity bills and determine the capacity needed per work center to run the following master schedule: Week Product C Product D 1 50 20 2 40 25 3 45 20 Week 2. Week 3 Week 1 D D U Work Center D 100 200 300 2. There are two products being produced by a firm with the following bills of material: D Q (3) P (2) R S (2) Routing Information (all times in hours) Operatio n Product Lot Size /Part 20 D 40 P 100 70 50 R S 100 S 100 Work Center 100 100 200 300 200 300 200 300 1 of 1 1 of 1 1 of 1 1 of 1 1 of 2 2 of 2 1 of 2 2 of 2 Setup hours 0.6 0.8 1 2 1.6 0.8 1.2 0.5 Run Time Per Unit 0.7 1.2 0.4 0.7 0.5 1.2 0.5 0.9 Setup per part .03 .02 .004 .029 .032 .016 .012 .005 Total Time .73 1.22 .404 .729 .532 1.216 .512 .905 50 per With this information, set up the capacity bills and determine the capacity needed work center to run the following master schedule: Week Product C Product D 1 50 20 2 40 25 3 45 20 Week 2 Week 1 Week 3 Work Center U D D D 100 200 300 2. There are two products being produced by a firm with the following bills of material: D P (2) R Q(3) 5 (2) Routing Information (all times in hours) Operatio Setup per part n .03 Product Lot Size /Part 20 40 100 70 50 50 100 100 SUAAO Work Center 100 100 200 300 200 300 200 300 1 of 1 1 of 1 1 of 1 1 of 1 1 of 2 2 of 2 1 of 2 2 of 2 Setup Run Time hours Per Unit 0.6 0.7 0.8 1.2 1 0.4 2 0.7 1.6 0.8 1.2. 1.2 0.5 0.5 0.9 Total Time .73 1.22 .404 .729 -532 1.216 -512 .905 .02 .004 .029 .032 .016 .012 .005 0.5 With this information, set up the capacity bills and determine the capacity needed per work center to run the following master schedule: Week Product C Product D 1 50 20 2 40 25 3 45 20 Week 2. Week 3 Week 1 D D U Work Center D 100 200 300 2. There are two products being produced by a firm with the following bills of material: D Q (3) P (2) R S (2) Routing Information (all times in hours) Operatio n Product Lot Size /Part 20 D 40 P 100 70 50 R S 100 S 100 Work Center 100 100 200 300 200 300 200 300 1 of 1 1 of 1 1 of 1 1 of 1 1 of 2 2 of 2 1 of 2 2 of 2 Setup hours 0.6 0.8 1 2 1.6 0.8 1.2 0.5 Run Time Per Unit 0.7 1.2 0.4 0.7 0.5 1.2 0.5 0.9 Setup per part .03 .02 .004 .029 .032 .016 .012 .005 Total Time .73 1.22 .404 .729 .532 1.216 .512 .905 50 per With this information, set up the capacity bills and determine the capacity needed work center to run the following master schedule: Week Product C Product D 1 50 20 2 40 25 3 45 20 Week 2 Week 1 Week 3 Work Center U D D D 100 200 300