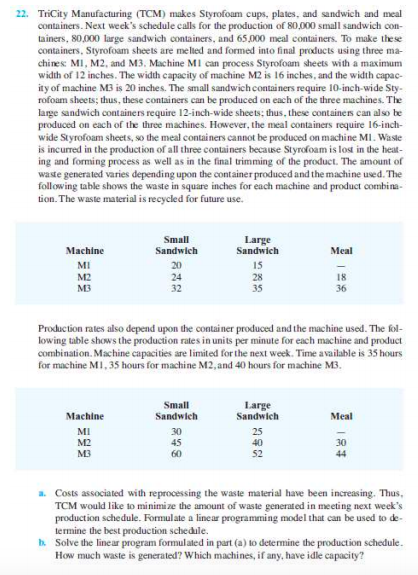

22. TriCity Manufacturing (TCM) makes Styrofoam cups, plates, and sandwich and meal containers. Next week's schedule calls for the production of 80,000 small sandwich con- lainers, 80.000 large sandwich containers, and 65000 meal containers. To make these containers. Styrofoam sheets are melted and formed into final products using three ma- chines MI, M2, and M3. Machine MI can process Styrofoam sheets with a maximum width of 12 inches. The width capacity of machine M2 is 16 inches, and the width capac- ity of machine M3 is 20 inches. The small sandwich containers require 10-inch-wide Sty- rofoam sheets; thus, these containers can be produced on each of the three machines. The large sandwich containers require 12-inch-wide sheets; thus, these containers can also be produced on each of the three machines. However, the meal containers require 16-inch- wide Styrofoam sheets, so the meal containers cannot be produced on machine MI. Waste is incurred in the production of all three containers because Styrofoam is lost in the heat- ing and forming process as well as in the final trimming of the product. The amount of waste generated varies depending upon the container produced and the machine used. The following table shows the waste in square inches for each machine and product combina- tion. The waste material is recycled for future use. Small Large Machine Sandwich Sandwich Meal MI 20 15 M2 24 28 18 M3 32 35 36 Production rates also depend upon the container produced and the machine used. The fol- lowing table shows the production rates in units per minute for each machine and product combination. Machine capacities are limited for the next week. Time available is 35 hours for machine MI, 35 hours for machine M2, and 40 hours for machine M3. Small Large Machine Sandwich Sandwich Meal MI 30 25 M2 45 40 30 M3 60 52 44 a. Costs associated with reprocessing the waste material have been increasing. Thus. TCM would like to minimize the amount of waste generated in meeting next week's production schedule. Formulate a linear programming model that can be used to de- termine the best production schedule. b. Solve the linear program formulated in part (a) to determine the production schedule. How much waste is generated? Which machines, if any, have idle capacity