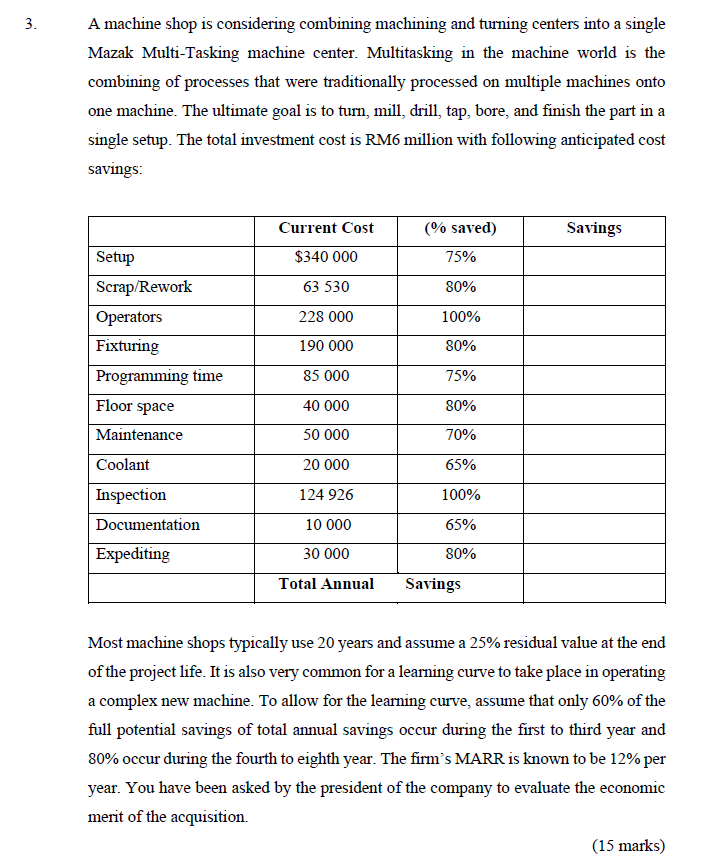

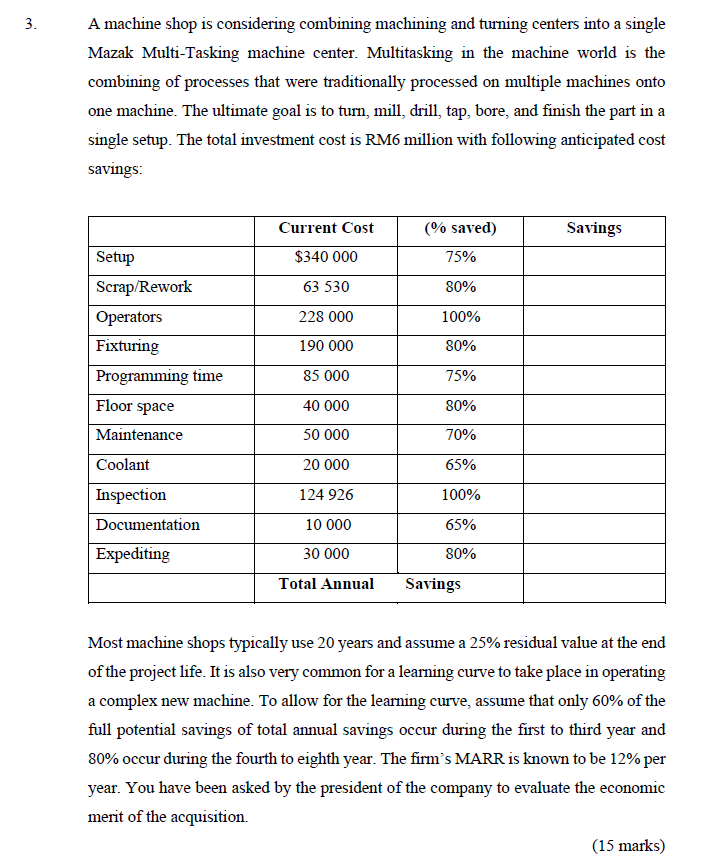

3. A machine shop is considering combining machining and turning centers into a single Mazak Multi-Tasking machine center. Multitasking in the machine world is the combining of processes that were traditionally processed on multiple machines onto one machine. The ultimate goal is to tum, mill, drill, tap, bore, and finish the part in a single setup. The total investment cost is RM6 million with following anticipated cost savings: Current Cost (% saved) Savings $340 000 75% 63 530 80% Setup Scrap/Rework Operators Fixturing Programming time 228 000 100% 190 000 80% 85 000 75% Floor space 40 000 80% 50 000 70% 20 000 65% Maintenance Coolant Inspection Documentation Expediting 124 926 100% 10 000 65% 30 000 80% Total Annual Savings Most machine shops typically use 20 years and assume a 25% residual value at the end of the project life. It is also very common for a learning curve to take place in operating a complex new machine. To allow for the learning curve, assume that only 60% of the full potential savings of total annual savings occur during the first to third year and 80% occur during the fourth to eighth year. The firm's MARR is known to be 12% per year. You have been asked by the president of the company to evaluate the economic merit of the acquisition. (15 marks) 3. A machine shop is considering combining machining and turning centers into a single Mazak Multi-Tasking machine center. Multitasking in the machine world is the combining of processes that were traditionally processed on multiple machines onto one machine. The ultimate goal is to tum, mill, drill, tap, bore, and finish the part in a single setup. The total investment cost is RM6 million with following anticipated cost savings: Current Cost (% saved) Savings $340 000 75% 63 530 80% Setup Scrap/Rework Operators Fixturing Programming time 228 000 100% 190 000 80% 85 000 75% Floor space 40 000 80% 50 000 70% 20 000 65% Maintenance Coolant Inspection Documentation Expediting 124 926 100% 10 000 65% 30 000 80% Total Annual Savings Most machine shops typically use 20 years and assume a 25% residual value at the end of the project life. It is also very common for a learning curve to take place in operating a complex new machine. To allow for the learning curve, assume that only 60% of the full potential savings of total annual savings occur during the first to third year and 80% occur during the fourth to eighth year. The firm's MARR is known to be 12% per year. You have been asked by the president of the company to evaluate the economic merit of the acquisition. (15 marks)