Answered step by step

Verified Expert Solution

Question

1 Approved Answer

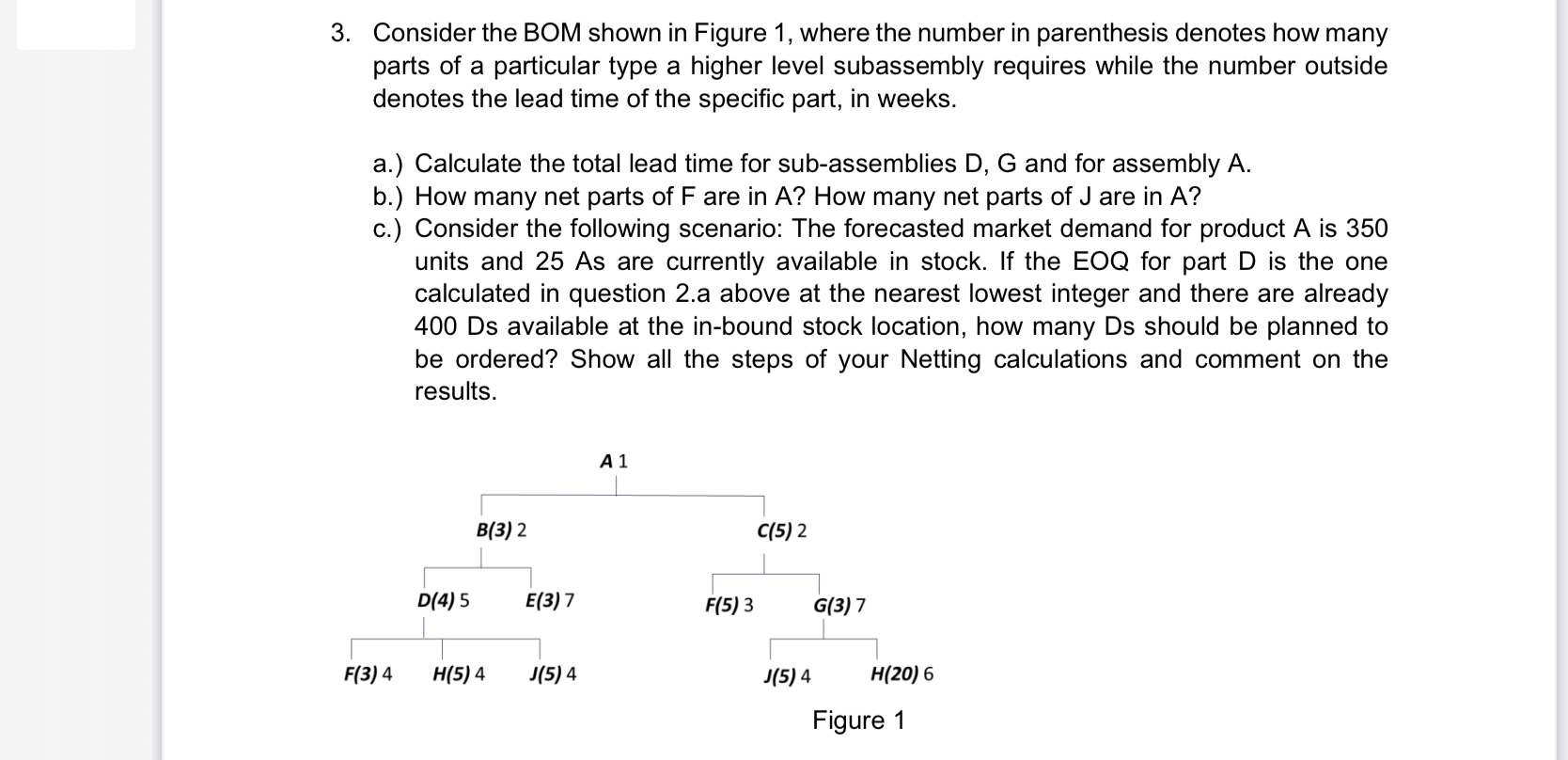

3. Consider the BOM shown in Figure 1, where the number in parenthesis denotes how many parts of a particular type a higher level

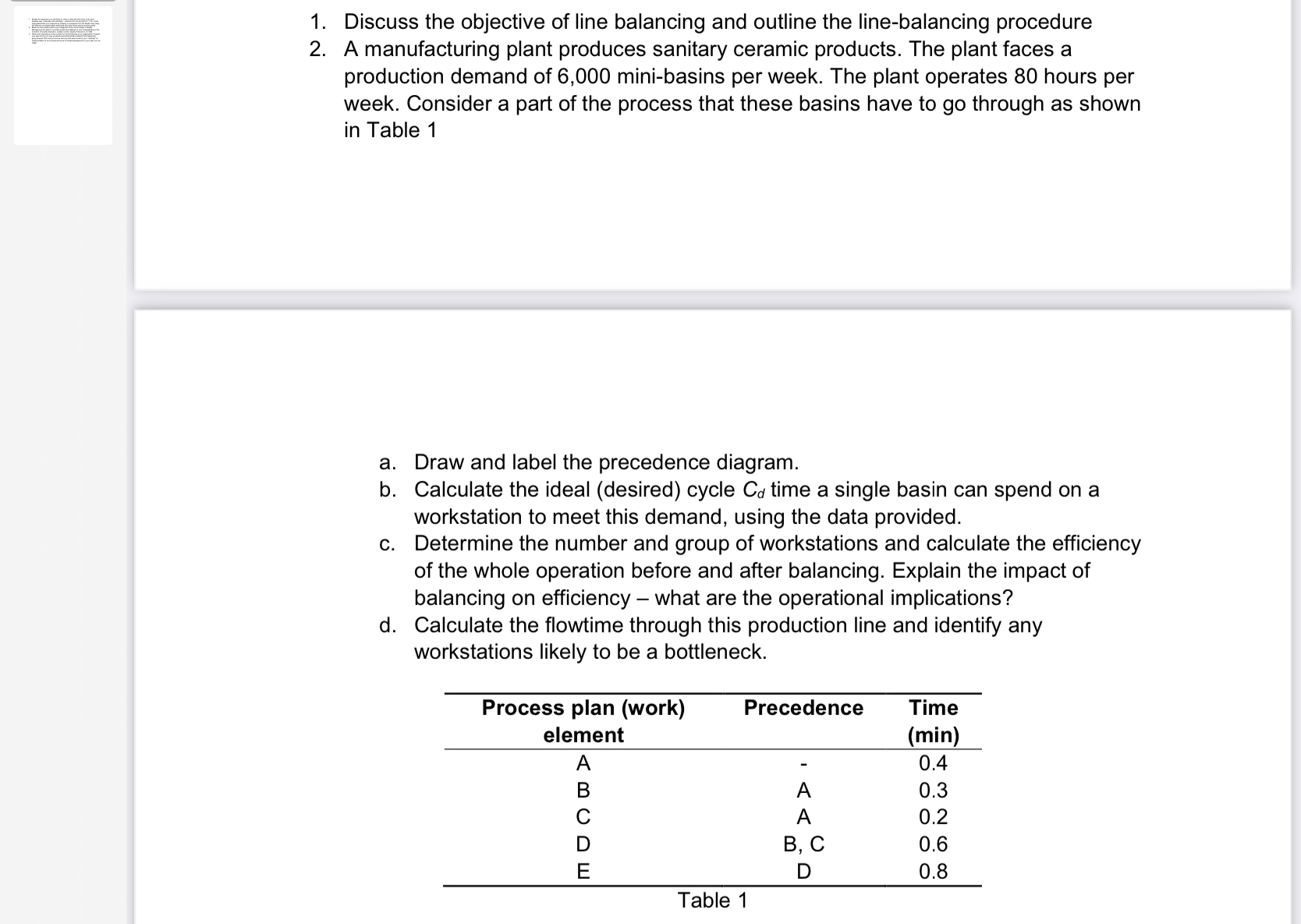

3. Consider the BOM shown in Figure 1, where the number in parenthesis denotes how many parts of a particular type a higher level subassembly requires while the number outside denotes the lead time of the specific part, in weeks. a.) Calculate the total lead time for sub-assemblies D, G and for assembly A. b.) How many net parts of F are in A? How many net parts of J are in A? c.) Consider the following scenario: The forecasted market demand for product A is 350 units and 25 As are currently available in stock. If the EOQ for part D is the one calculated in question 2.a above at the nearest lowest integer and there are already 400 Ds available at the in-bound stock location, how many Ds should be planned to be ordered? Show all the steps of your Netting calculations and comment on the results. F(3) 4 D(4) 5 B(3) 2 H(5) 4 E(3) 7 J(5) 4 A 1 C(5) 2 F(5) 3 J(5) 4 G(3) 7 H(20) 6 Figure 1 1. Discuss the objective of line balancing and outline the line-balancing procedure 2. A manufacturing plant produces sanitary ceramic products. The plant faces a production demand of 6,000 mini-basins per week. The plant operates 80 hours per week. Consider a part of the process that these basins have to go through as shown in Table 1 a. Draw and label the precedence diagram. b. Calculate the ideal (desired) cycle Ca time a single basin can spend on a workstation to meet this demand, using the data provided. c. Determine the number and group of workstations and calculate the efficiency of the whole operation before and after balancing. Explain the impact of balancing on efficiency - what are the operational implications? d. Calculate the flowtime through this production line and identify any workstations likely to be a bottleneck. Process plan (work) element A BCDE Precedence Table 1 A A B, C D Time (min) 0.4 0.3 0.2 0.6 0.8

Step by Step Solution

There are 3 Steps involved in it

Step: 1

3 a Total lead time for subassembly D D requires 4 parts of itself Lead time of D is 5 weeks So tota...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started