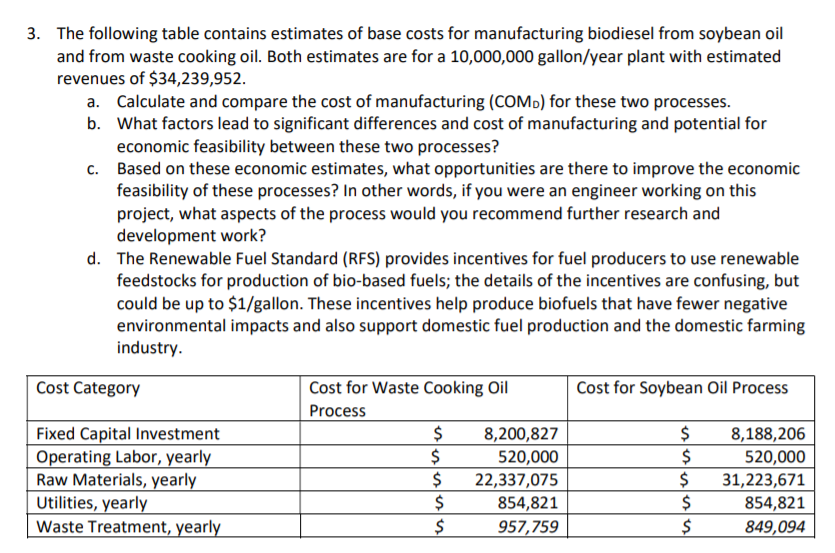

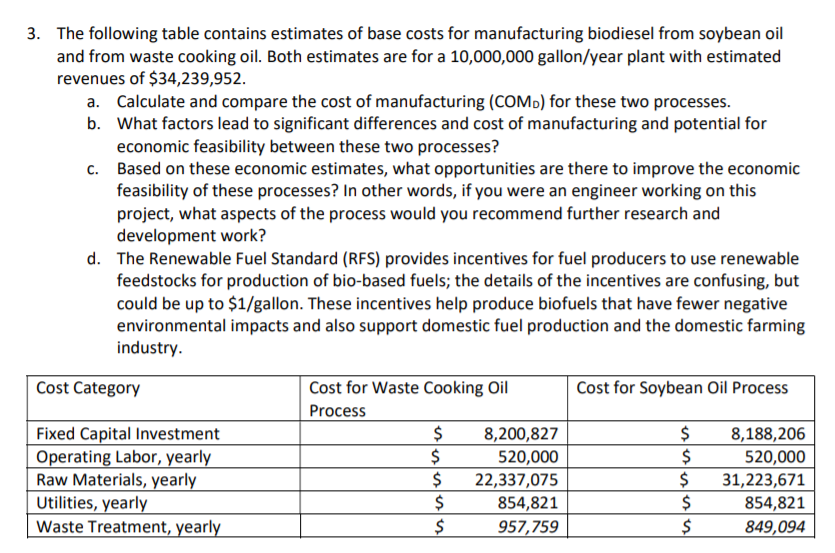

3. The following table contains estimates of base costs for manufacturing biodiesel from soybean oil and from waste cooking oil. Both estimates are for a 10,000,000 gallon/year plant with estimated revenues of $34,239,952. a. Calculate and compare the cost of manufacturing (COM) for these two processes. b. What factors lead to significant differences and cost of manufacturing and potential for economic feasibility between these two processes? C. Based on these economic estimates, what opportunities are there to improve the economic feasibility of these processes? In other words, if you were an engineer working on this project, what aspects of the process would you recommend further research and development work? d. The Renewable Fuel Standard (RFS) provides incentives for fuel producers to use renewable feedstocks for production of bio-based fuels; the details of the incentives are confusing, but could be up to $1/gallon. These incentives help produce biofuels that have fewer negative environmental impacts and also support domestic fuel production and the domestic farming industry. Cost Category Cost for Soybean Oil Process Fixed Capital Investment Operating Labor, yearly Raw Materials, yearly Utilities, yearly Waste Treatment, yearly Cost for Waste Cooking Oil Process $ 8,200,827 $ 520,000 $ 22,337,075 $ 854,821 $ 957,759 $ $ $ $ $ 8,188,206 520,000 31,223,671 854,821 849,094 3. The following table contains estimates of base costs for manufacturing biodiesel from soybean oil and from waste cooking oil. Both estimates are for a 10,000,000 gallon/year plant with estimated revenues of $34,239,952. a. Calculate and compare the cost of manufacturing (COM) for these two processes. b. What factors lead to significant differences and cost of manufacturing and potential for economic feasibility between these two processes? C. Based on these economic estimates, what opportunities are there to improve the economic feasibility of these processes? In other words, if you were an engineer working on this project, what aspects of the process would you recommend further research and development work? d. The Renewable Fuel Standard (RFS) provides incentives for fuel producers to use renewable feedstocks for production of bio-based fuels; the details of the incentives are confusing, but could be up to $1/gallon. These incentives help produce biofuels that have fewer negative environmental impacts and also support domestic fuel production and the domestic farming industry. Cost Category Cost for Soybean Oil Process Fixed Capital Investment Operating Labor, yearly Raw Materials, yearly Utilities, yearly Waste Treatment, yearly Cost for Waste Cooking Oil Process $ 8,200,827 $ 520,000 $ 22,337,075 $ 854,821 $ 957,759 $ $ $ $ $ 8,188,206 520,000 31,223,671 854,821 849,094