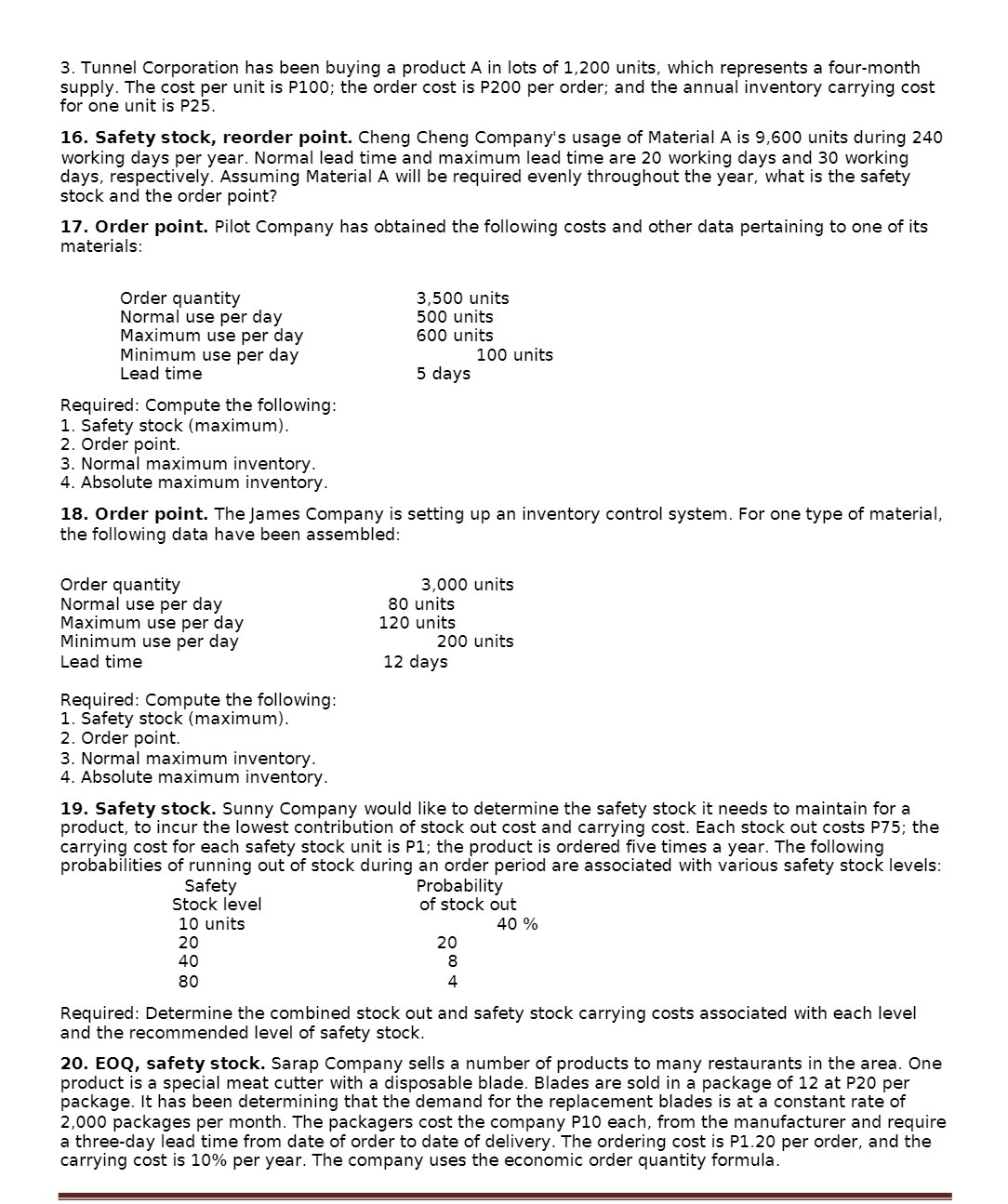

3. Tunnel Corporation has been buying a product A in lots of 1,200 units, which represents a four-month supply. The cost per unit is P100; the order cost is P200 per order; and the annual inventory carrying cost for one unit is P25. 16. Safety stock, reorder point. Cheng Cheng Company's usage of Material A is 9,600 units during 240 working days per year. Normal lead time and maximum lead time are 20 working days and 30 working days, respectively. Assuming Material A will be required evenly throughout the year, what is the safety stock and the order point? 17. Order point. Pilot Company has obtained the following costs and other data pertaining to one of its materials: Order quantity 3,500 units Normal use per day 500 units Maximum use per day 600 units Minimum use per day 100 units Lead time 5 days Required: Compute the following: 1. Safety stock (maximum). 2. Order point. 3. Normal maximum inventory. 4. Absolute maximum inventory. 18. Order point. The james Company is setting up an inventory control system. For one type of material, the following data have been assembled: Order quantity 3,000 units Normal use per day 80 units Maximum use per day 120 units Minimum use per day 200 units Lead time 12 days Required: Compute the following: 1. Safety stock (maximum). 2. Order point. 3. Normal maximum inventory. 4. Absolute maximum inventory. 19. Safety stock. Sunny Company would like to determine the safety stock it needs to maintain for a product, to incur the lowest contribution of stock out cost and carrying cost. Each stock out costs P75; the carrying cost for each safety stock unit is P1; the product is ordered ve times a year. The following probabilities of running out of stock during an order period are associated with various safety stock levels: Safety Probability Stock level of stock out 10 units 40 % 20 20 40 8 80 4 Required: Determine the combined stock out and safety stock carrying costs associated with each level and the recommended level of safety stock. 20. EOQ, safety stock. Sarap Company sells a number of products to many restaurants in the area. One product is a special meat cutter with a disposable blade. Blades are sold in a package of 12 at P20I per package. It has been determining that the demand for the replacement blades is at a constant rate of 2,000 packages per month. The packagers cost the company P10 each, from the manufacturer and require a three-day lead time from date of order to date of delivery. The ordering cost is P1.20 per order, and the carrying cost is 10% per year. The company uses the economic order quantity formula