Question

3.Prepare the direct material usage and purchases budgets for January 2018. 4.Prepare a direct manufacturing labor costs budget for January 2018. 5.Prepare a manufacturing overhead

3.Prepare the direct material usage and purchases budgets for January 2018.

4.Prepare a direct manufacturing labor costs budget for January 2018.

5.Prepare a manufacturing overhead costs budget for January 2018.

6.What is the budgeted manufacturing overhead rate for January 2018?

7.What is the budgeted manufacturing overhead cost per output unit in January 2018?

8.Calculate the cost of a snowboard manufactured in January 2018.

9.Prepare an ending inventory budget for both direct materials and finished goods for January 2018.

10.Prepare a cost of goods sold budget for January 2018.

11.Prepare the budgeted income statement for Slaggs, Inc., for January 2018.

12.What questions might the CEO ask the management team when reviewing the budget? Should the CEO set stretch targets? Explain briefly.

13.How does preparing the budget help Slaggs's management team better manage the company?

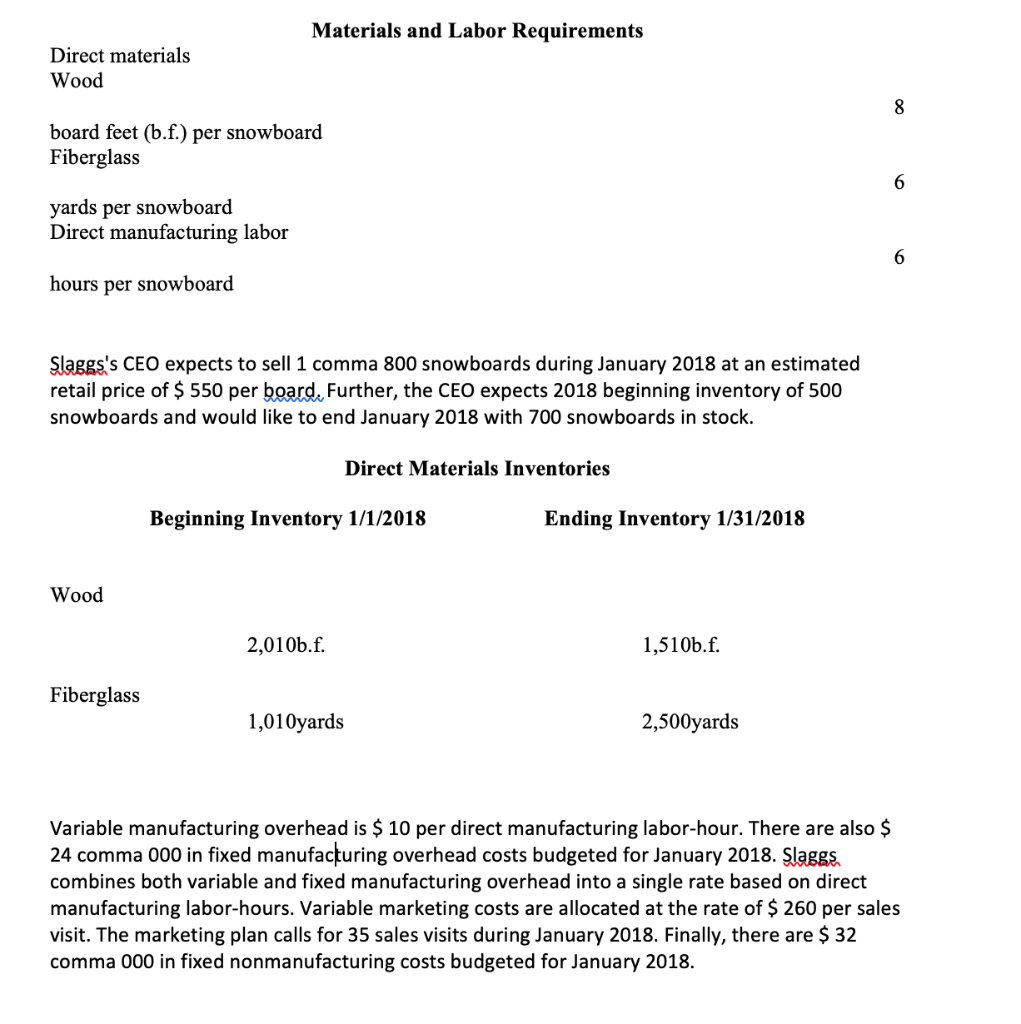

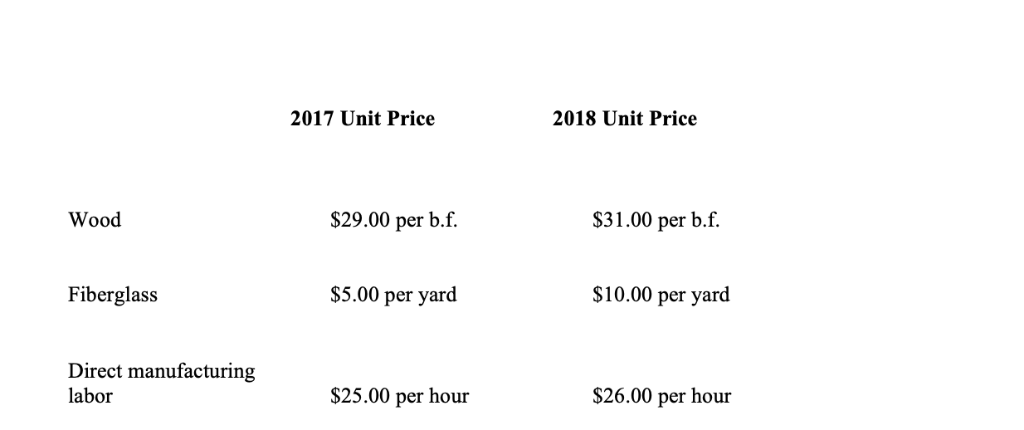

Materials and Labor Requirements Direct materials Wood board feet (b.f.) per snowboard Fiberglass yards per snowboard Direct manufacturing labor hours per snowboard laggs's CEO expects to sell 1 comma 800 snowboards during January 2018 at an estimated retail price of $ 550 per board. Further, the CEO expects 2018 beginning inventory of 500 snowboards and would like to end January 2018 with 700 snowboards in stock. Direct Materials Inventories Beginning Inventory 1/1/2018 Ending Inventory 1/31/2018 Wood 2,010b.f. 1,510b.f. Fiberglass 1,010yards 2,500yards Variable manufacturing overhead is $10 per direct manufacturing labor-hour. There are also $ 24 comma 000 in fixed manufacturing overhead costs budgeted for January 2018. Slaggs combines both variable and fixed manufacturing overhead into a single rate based on diredt manufacturing labor-hours. Variable marketing costs are allocated at the rate of $ 260 per sales visit. The marketing plan calls for 35 sales visits during January 2018. Finally, there are $ 32 comma 000 in fixed nonmanufacturing costs budgeted for January 2018. Materials and Labor Requirements Direct materials Wood board feet (b.f.) per snowboard Fiberglass yards per snowboard Direct manufacturing labor hours per snowboard laggs's CEO expects to sell 1 comma 800 snowboards during January 2018 at an estimated retail price of $ 550 per board. Further, the CEO expects 2018 beginning inventory of 500 snowboards and would like to end January 2018 with 700 snowboards in stock. Direct Materials Inventories Beginning Inventory 1/1/2018 Ending Inventory 1/31/2018 Wood 2,010b.f. 1,510b.f. Fiberglass 1,010yards 2,500yards Variable manufacturing overhead is $10 per direct manufacturing labor-hour. There are also $ 24 comma 000 in fixed manufacturing overhead costs budgeted for January 2018. Slaggs combines both variable and fixed manufacturing overhead into a single rate based on diredt manufacturing labor-hours. Variable marketing costs are allocated at the rate of $ 260 per sales visit. The marketing plan calls for 35 sales visits during January 2018. Finally, there are $ 32 comma 000 in fixed nonmanufacturing costs budgeted for January 2018Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started