Answered step by step

Verified Expert Solution

Question

1 Approved Answer

4 marks for Draw a flowchart and identified and stated assumptions and clearly labelled diagram 4 marks for correctly labelled flow chart including all known

4 marks for Draw a flowchart and identified and stated assumptions and clearly labelled diagram

4 marks for correctly labelled flow chart including all known and unknowns plus degree of freedom analysis for each part.

2 marks for showing full working attempt but incorrect.

6 marks for correct answers (oral explanation as well as inside the assignment)

2 correct units and significant figures

2 answer readable and neatly set out

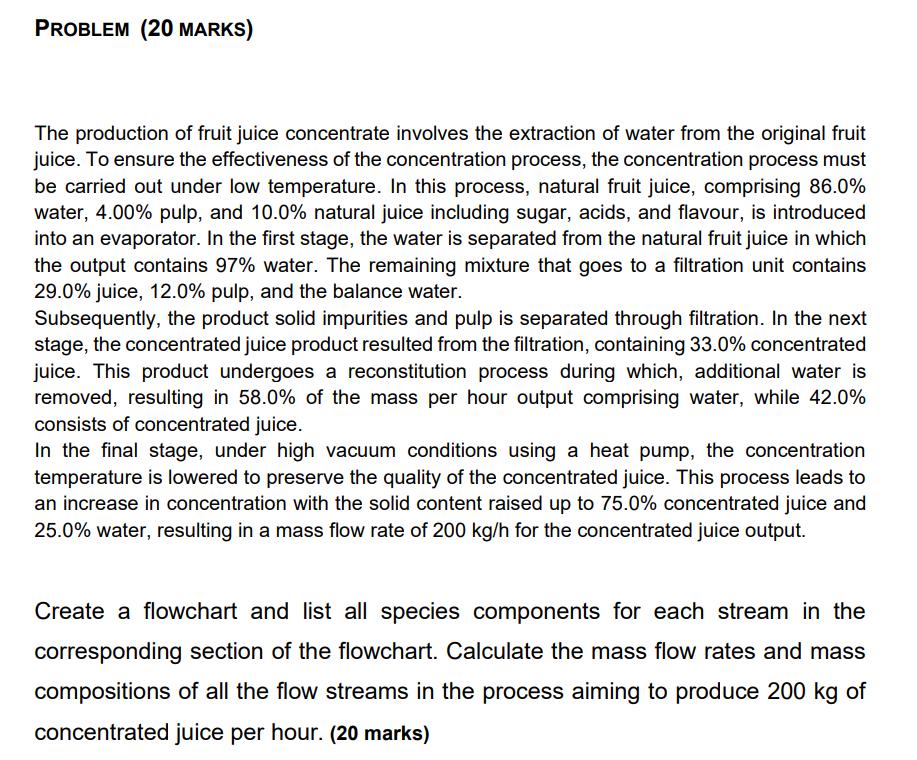

PROBLEM (20 MARKS) The production of fruit juice concentrate involves the extraction of water from the original fruit juice. To ensure the effectiveness of the concentration process, the concentration process must be carried out under low temperature. In this process, natural fruit juice, comprising 86.0% water, 4.00% pulp, and 10.0% natural juice including sugar, acids, and flavour, is introduced into an evaporator. In the first stage, the water is separated from the natural fruit juice in which the output contains 97% water. The remaining mixture that goes to a filtration unit contains 29.0% juice, 12.0% pulp, and the balance water. Subsequently, the product solid impurities and pulp is separated through filtration. In the next stage, the concentrated juice product resulted from the filtration, containing 33.0% concentrated juice. This product undergoes a reconstitution process during which, additional water is removed, resulting in 58.0% of the mass per hour output comprising water, while 42.0% consists of concentrated juice. In the final stage, under high vacuum conditions using a heat pump, the concentration temperature is lowered to preserve the quality of the concentrated juice. This process leads to an increase in concentration with the solid content raised up to 75.0% concentrated juice and 25.0% water, resulting in a mass flow rate of 200 kg/h for the concentrated juice output. Create a flowchart and list all species components for each stream in the corresponding section of the flowchart. Calculate the mass flow rates and mass compositions of all the flow streams in the process aiming to produce 200 kg of concentrated juice per hour. (20 marks)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started