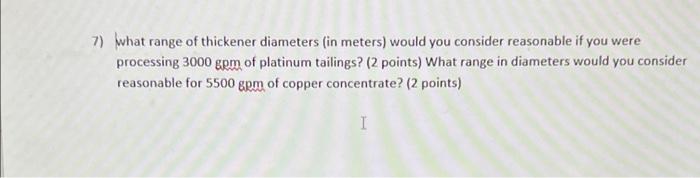

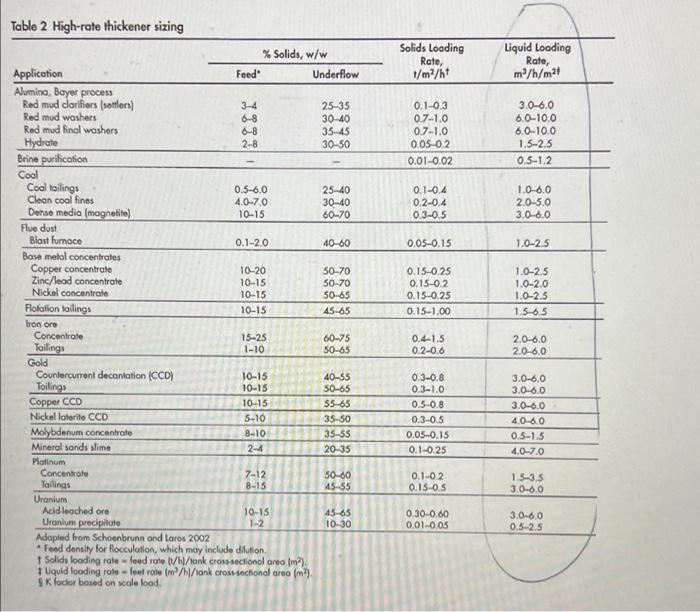

7) What range of thickener diameters (in meters) would you consider reasonable if you were processing 3000 gem of platinum tailings? (2 points) What range in diameters would you consider reasonable for 5500 grm of copper concentrate? (2 points) I Table 2 High-rate thickener sizing Solids Loading Rate, 1/m2/ht Liquid looding Rate, m/h/m2! 0.1-0.3 0.7-1.0 0.7-1.0 0.05-02 0.01-0.02 3.0-6.0 6.0-10.0 6.0-10.0 1.5-2.5 0.5-1.2 0.1-0.4 0.2-0.4 0.3-0.5 1.0-6.0 2.0-5.0 3.0-6.0 0.05-0.15 1.0-2.5 0.15-0.25 0.15-0.2 0.15-0.25 0.15-1.00 % Solids, W/W Application Feed Underflow Alumina, Bayer process Red mud clarifiers softler) 3-4 25-35 Red mud washers 6-8 30-40 Red mud Rinol washers 68 35-45 Hydrate 2-8 30-50 Brine purification Cool Coal tailings 0.5-6.0 25-40 Clean coal fines 4.0-7.0 30-40 Derse media (magnolite) 10-15 60-70 Flue dust Blast furnace 0.1-2.0 40-60 Base metal concentrates Copper concentrate 10-20 50-70 Zinc/lead concentrate 10-15 50-70 Nickel concentrate 10-15 50-65 Flotation toilings 10-15 45-65 Iron ore Concentrale 15-25 60-75 Tailings 1-10 50-65 Gold Countercurrent decantation (CCD) 10-15 40-55 Toilings 10-15 50-65 Copper CCD 10-15 55-65 Nickel loterite CCD 5-10 35-50 Molybdenum concentrate 8-10 35-55 Mineral sands alime 2-4 20-35 Platinum Concentrate 7-12 30-60 Tailings 8-15 45-55 Uranium Acid leoched ore 10-15 45-85 Uranium precipitole 1-2 10-30 Adopted from Schoenbrunn and Laros 2002 Feed density for Flocculation, which may include dilution Solids looding role - leed rate (VW/tank cross-sectional area (m) Uquid looding role -leet rate (m//onk cross sectional area (m) SK focior bosed on solo load 1.0-25 1.0-2.0 1.0-2.5 1.5-6.5 0.4-1.5 0.2-0.6 2.0-6.0 2.0-6.0 0.3-0.8 0.3-1.0 0.5-0.8 0.3-0.5 0.05-0.15 0.1-0.25 3.0-6.0 3.0-6.0 3.0-6.0 4.0-6.0 0.5-1.5 40-70 0.1-0.2 0.15-0.5 1.5-3.5 3.0-6.0 0.30-0.60 0.01-0.05 3.0-6.0 0.5-2.5 7) What range of thickener diameters (in meters) would you consider reasonable if you were processing 3000 gem of platinum tailings? (2 points) What range in diameters would you consider reasonable for 5500 grm of copper concentrate? (2 points) I Table 2 High-rate thickener sizing Solids Loading Rate, 1/m2/ht Liquid looding Rate, m/h/m2! 0.1-0.3 0.7-1.0 0.7-1.0 0.05-02 0.01-0.02 3.0-6.0 6.0-10.0 6.0-10.0 1.5-2.5 0.5-1.2 0.1-0.4 0.2-0.4 0.3-0.5 1.0-6.0 2.0-5.0 3.0-6.0 0.05-0.15 1.0-2.5 0.15-0.25 0.15-0.2 0.15-0.25 0.15-1.00 % Solids, W/W Application Feed Underflow Alumina, Bayer process Red mud clarifiers softler) 3-4 25-35 Red mud washers 6-8 30-40 Red mud Rinol washers 68 35-45 Hydrate 2-8 30-50 Brine purification Cool Coal tailings 0.5-6.0 25-40 Clean coal fines 4.0-7.0 30-40 Derse media (magnolite) 10-15 60-70 Flue dust Blast furnace 0.1-2.0 40-60 Base metal concentrates Copper concentrate 10-20 50-70 Zinc/lead concentrate 10-15 50-70 Nickel concentrate 10-15 50-65 Flotation toilings 10-15 45-65 Iron ore Concentrale 15-25 60-75 Tailings 1-10 50-65 Gold Countercurrent decantation (CCD) 10-15 40-55 Toilings 10-15 50-65 Copper CCD 10-15 55-65 Nickel loterite CCD 5-10 35-50 Molybdenum concentrate 8-10 35-55 Mineral sands alime 2-4 20-35 Platinum Concentrate 7-12 30-60 Tailings 8-15 45-55 Uranium Acid leoched ore 10-15 45-85 Uranium precipitole 1-2 10-30 Adopted from Schoenbrunn and Laros 2002 Feed density for Flocculation, which may include dilution Solids looding role - leed rate (VW/tank cross-sectional area (m) Uquid looding role -leet rate (m//onk cross sectional area (m) SK focior bosed on solo load 1.0-25 1.0-2.0 1.0-2.5 1.5-6.5 0.4-1.5 0.2-0.6 2.0-6.0 2.0-6.0 0.3-0.8 0.3-1.0 0.5-0.8 0.3-0.5 0.05-0.15 0.1-0.25 3.0-6.0 3.0-6.0 3.0-6.0 4.0-6.0 0.5-1.5 40-70 0.1-0.2 0.15-0.5 1.5-3.5 3.0-6.0 0.30-0.60 0.01-0.05 3.0-6.0 0.5-2.5