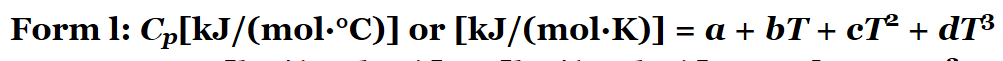

a * 10^-3; b * 10^-5; c * 10^-8; d * 10^-12

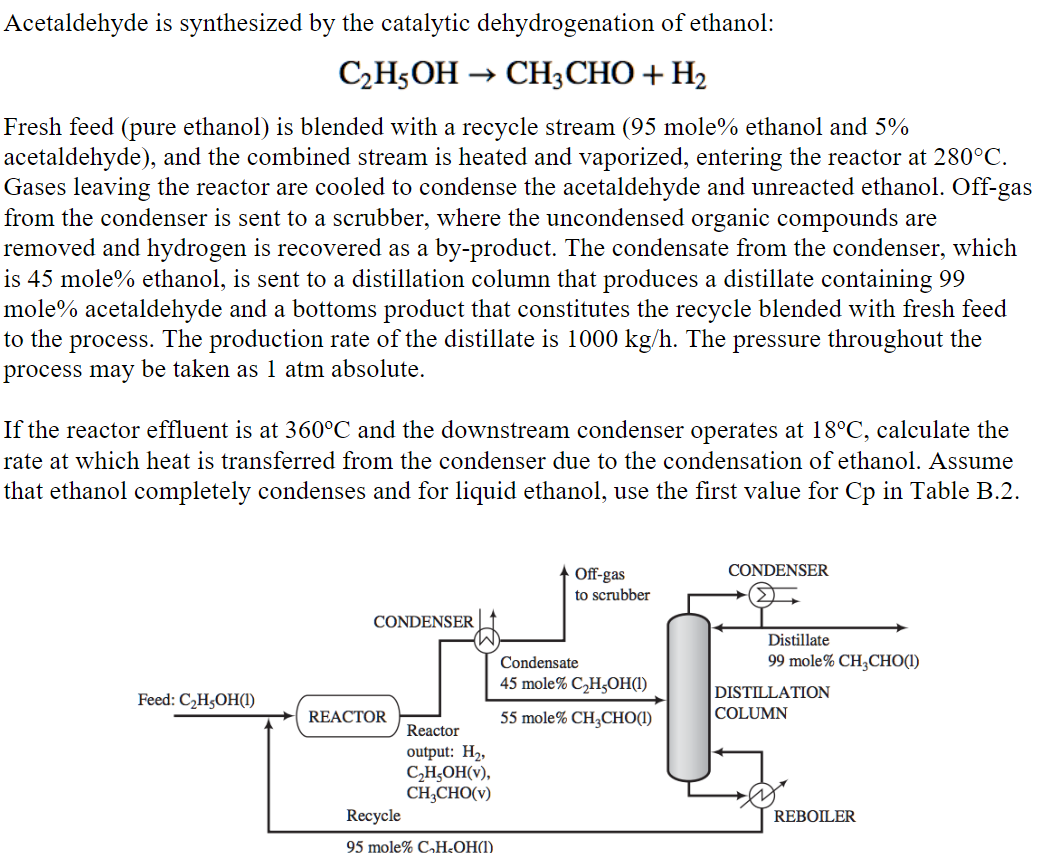

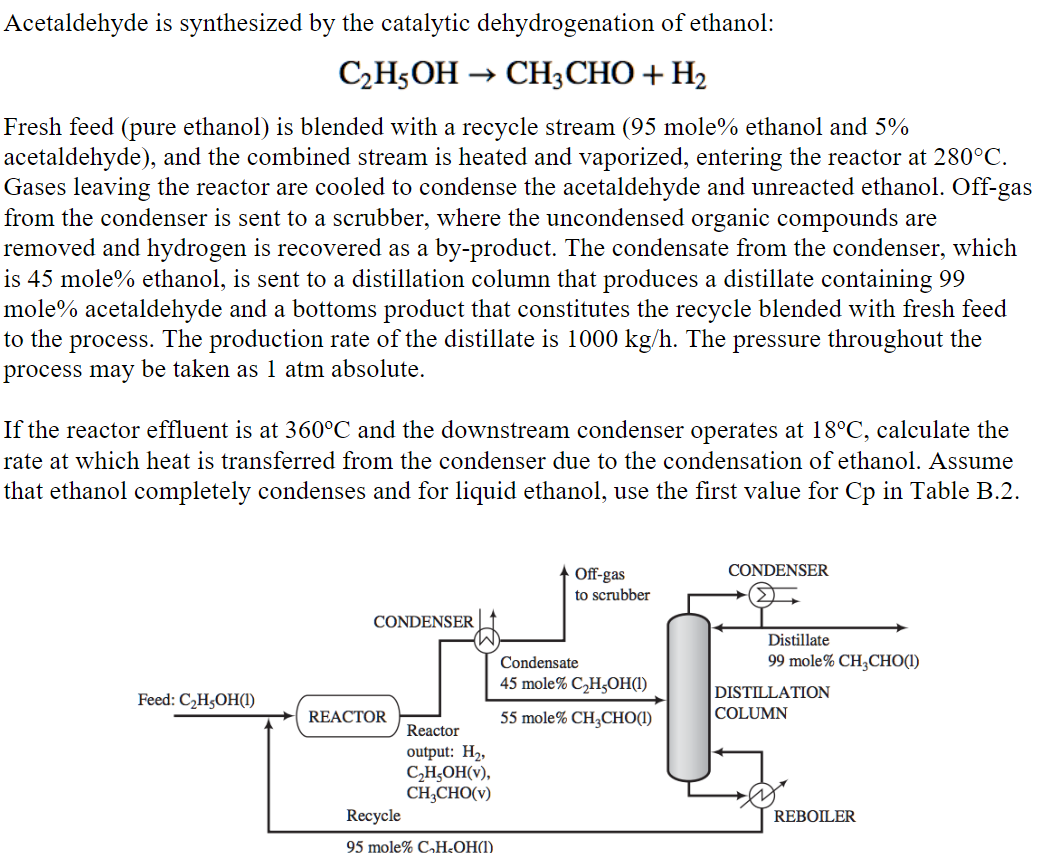

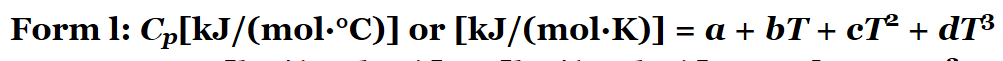

Acetaldehyde is synthesized by the catalytic dehydrogenation of ethanol: C2H5OH - CH3CHO + H2 Fresh feed (pure ethanol) is blended with a recycle stream (95 mole% ethanol and 5% acetaldehyde), and the combined stream is heated and vaporized, entering the reactor at 280C. Gases leaving the reactor are cooled to condense the acetaldehyde and unreacted ethanol. Off-gas from the condenser is sent to a scrubber, where the uncondensed organic compounds are removed and hydrogen is recovered as a by-product. The condensate from the condenser, which is 45 mole% ethanol, is sent to a distillation column that produces a distillate containing 99 mole% acetaldehyde and a bottoms product that constitutes the recycle blended with fresh feed to the process. The production rate of the distillate is 1000 kg/h. The pressure throughout the process may be taken as 1 atm absolute. If the reactor effluent is at 360C and the downstream condenser operates at 18C, calculate the rate at which heat is transferred from the condenser due to the condensation of ethanol. Assume that ethanol completely condenses and for liquid ethanol, use the first value for Cp in Table B.2. CONDENSER Off-gas to scrubber CONDENSER Condensate 45 mole% CH,OH(1) Distillate 99 mole% CHCHO1) DISTILLATION COLUMN Feed: C2H5OH(1) 55 mole% CHCHO1) REACTOR Reactor output: H, CH,OH(v), CHCHO(v) Recycle REBOILER 95 mole% CH2OH(I) Form 1: Cp[kJ/(molC)] or [kJ/(molK)] = a + bT + cT + dT3 = 61.34 15.72 -8749 19.83 Acetaldehyde is synthesized by the catalytic dehydrogenation of ethanol: C2H5OH - CH3CHO + H2 Fresh feed (pure ethanol) is blended with a recycle stream (95 mole% ethanol and 5% acetaldehyde), and the combined stream is heated and vaporized, entering the reactor at 280C. Gases leaving the reactor are cooled to condense the acetaldehyde and unreacted ethanol. Off-gas from the condenser is sent to a scrubber, where the uncondensed organic compounds are removed and hydrogen is recovered as a by-product. The condensate from the condenser, which is 45 mole% ethanol, is sent to a distillation column that produces a distillate containing 99 mole% acetaldehyde and a bottoms product that constitutes the recycle blended with fresh feed to the process. The production rate of the distillate is 1000 kg/h. The pressure throughout the process may be taken as 1 atm absolute. If the reactor effluent is at 360C and the downstream condenser operates at 18C, calculate the rate at which heat is transferred from the condenser due to the condensation of ethanol. Assume that ethanol completely condenses and for liquid ethanol, use the first value for Cp in Table B.2. CONDENSER Off-gas to scrubber CONDENSER Condensate 45 mole% CH,OH(1) Distillate 99 mole% CHCHO1) DISTILLATION COLUMN Feed: C2H5OH(1) 55 mole% CHCHO1) REACTOR Reactor output: H, CH,OH(v), CHCHO(v) Recycle REBOILER 95 mole% CH2OH(I) Form 1: Cp[kJ/(molC)] or [kJ/(molK)] = a + bT + cT + dT3 = 61.34 15.72 -8749 19.83