Answered step by step

Verified Expert Solution

Question

1 Approved Answer

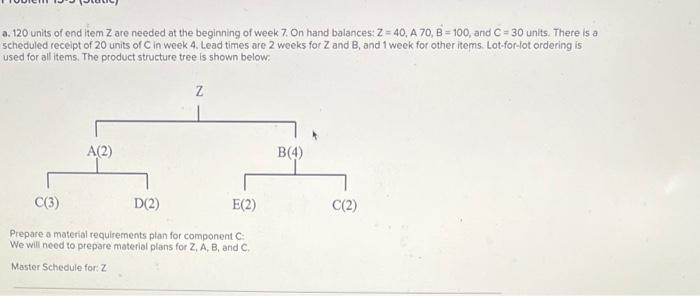

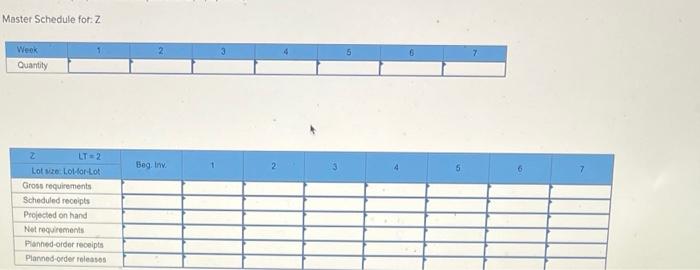

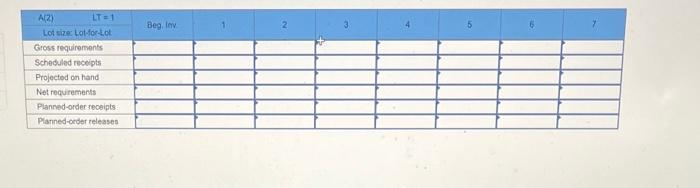

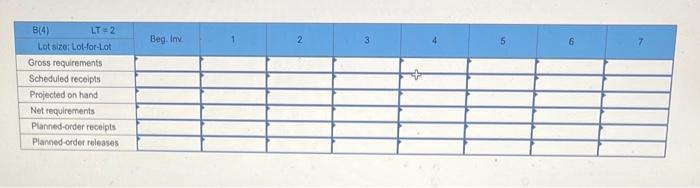

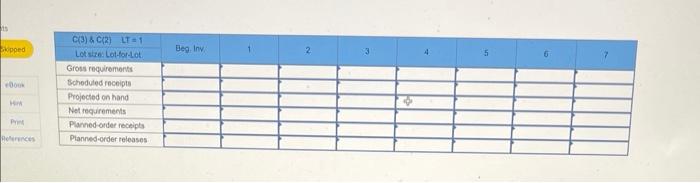

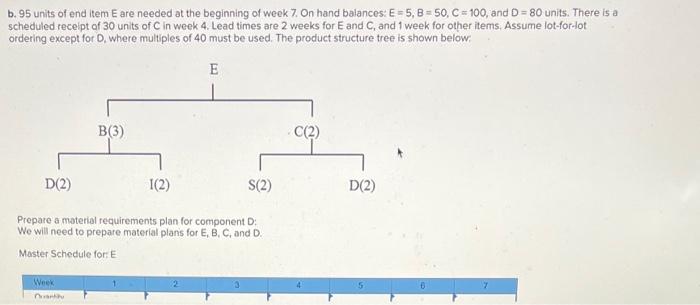

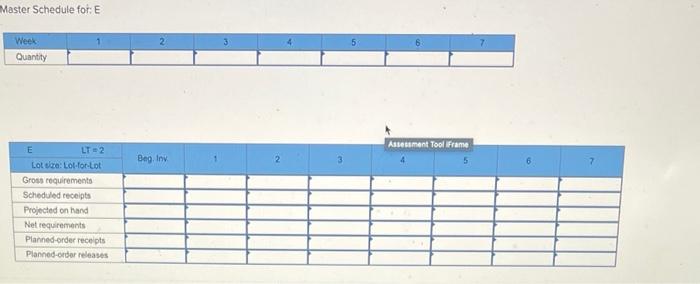

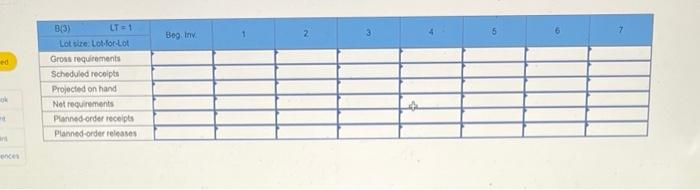

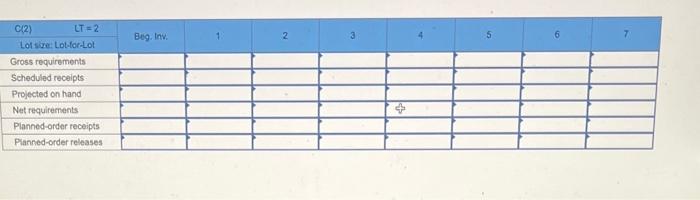

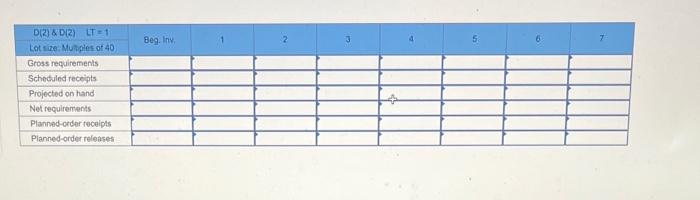

a. 120 units of end item Z are needed at the beginning of week 7 . On hand balances: Z=40,A70,B=100, and C=30 units. There is

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started