Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Q3. Consider the production problem facing a manufacturer of TARDIS with two models in its line- the type 40 and the type 50. Each

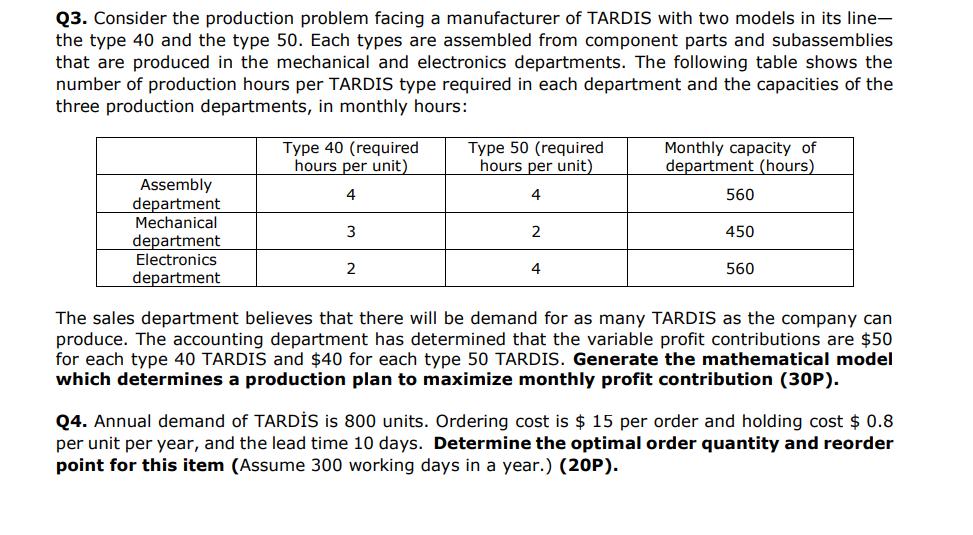

Q3. Consider the production problem facing a manufacturer of TARDIS with two models in its line- the type 40 and the type 50. Each types are assembled from component parts and subassemblies that are produced in the mechanical and electronics departments. The following table shows the number of production hours per TARDIS type required in each department and the capacities of the three production departments, in monthly hours: Assembly department Mechanical department Electronics department Type 40 (required hours per unit) 4 3 2 Type 50 (required hours per unit) 4 2 4 Monthly capacity of department (hours) 560 450 560 The sales department believes that there will be demand for as many TARDIS as the company can produce. The accounting department has determined that the variable profit contributions are $50 for each type 40 TARDIS and $40 for each type 50 TARDIS. Generate the mathematical model which determines a production plan to maximize monthly profit contribution (30P). Q4. Annual demand of TARDIS is 800 units. Ordering cost is $ 15 per order and holding cost $ 0.8 per unit per year, and the lead time 10 days. Determine the optimal order quantity and reorder point for this item (Assume 300 working days in a year.) (20P).

Step by Step Solution

★★★★★

3.37 Rating (150 Votes )

There are 3 Steps involved in it

Step: 1

Q3 Mathematical Model for Production Planning Let x Number of Type 40 TARDIS produced per month y Nu...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started