Answered step by step

Verified Expert Solution

Question

1 Approved Answer

(a) An aluminum part is subjected to die casting with an estimated cycle time of 25 s for a single-cavity die and an estimated

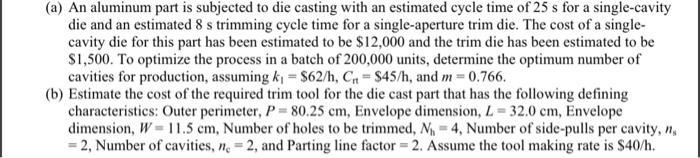

(a) An aluminum part is subjected to die casting with an estimated cycle time of 25 s for a single-cavity die and an estimated 8 s trimming cycle time for a single-aperture trim die. The cost of a single- cavity die for this part has been estimated to be $12,000 and the trim die has been estimated to be $1,500. To optimize the process in a batch of 200,000 units, determine the optimum number of cavities for production, assuming k, = $62/h, C= $45/h, and m = 0.766. (b) Estimate the cost of the required trim tool for the die cast part that has the following defining characteristics: Outer perimeter, P = 80.25 cm, Envelope dimension, L= 32.0 cm, Envelope dimension, W11.5 cm, Number of holes to be trimmed, N = 4, Number of side-pulls per cavity, n = 2, Number of cavities, n = 2, and Parting line factor =2. Assume the tool making rate is $40/h.

Step by Step Solution

★★★★★

3.31 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

a To determine the optimum number of cavities for production in a batch of 200000 units we need to consider the cycle times and costs associated with ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started