Question

A brief explanation of EAF steelmaking is in order. Making a heat of steel in an EAF (100 to 180 metric tons) takes about 90

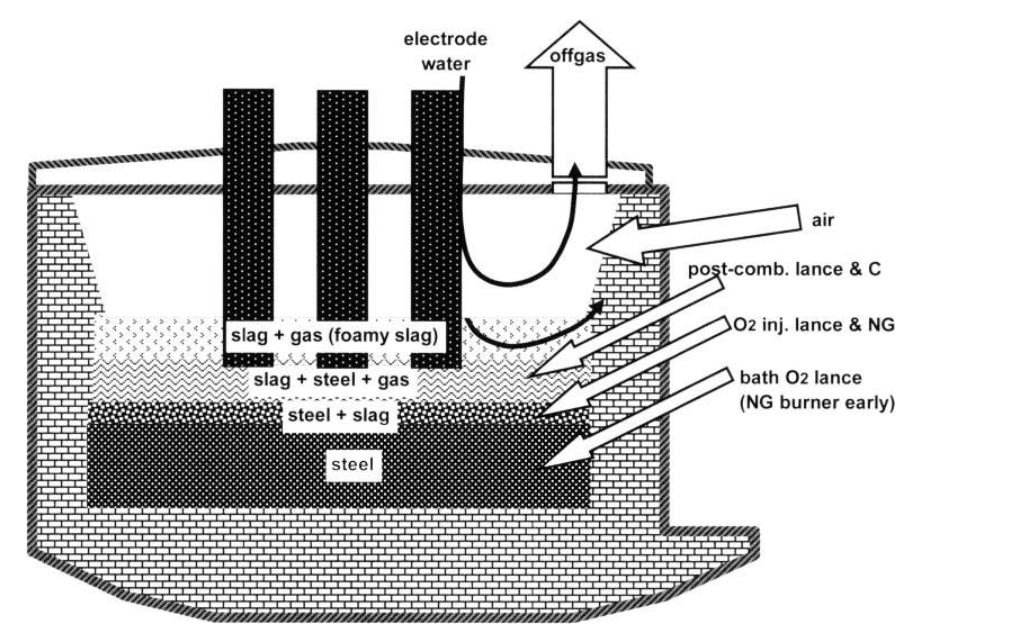

A brief explanation of EAF steelmaking is in order. Making a heat of steel in an EAF (100 to 180 metric tons) takes about 90 minutes from tap to tap. The charge consists of iron units (scrap iron, DRI, etc.), flux (lime, dolomite, etc.), and often some carbon (electrode scrap, coke, etc.). The furnace cover is lifted, and about one-third of the charge is placed in the furnace. The lid is repositioned, and the electrodes are lowered to the top of the charge. An arc is struck, and the electrodes melt a hole in the charge bed. Oxygenatural gas burners are used along the sidewalls to heat the charge. When the charge is mainly molten, the electrodes are raised, the lid removed, and more charge is placed in the furnace. The arc is again struck, and the charge melted. This is repeated for a third time. During the last stages of meltdown, oxygen, and carbon are injected into the slag to keep it foamy, while arc heating continues until the furnace contents reach the tap temperature, usually near 1650 C. Throughout the entire process, gas and fume are evolved and mixed with air in the upper part of the furnace and/or in the offtake duct. The off-gas is cleaned to remove dust, and the clean off-gas (CO2, H2O, and N2) is discharged. When the heat specifications are reached, the furnace is tapped and prepared for the next heat. Some slag may be left in the furnace to protect the lining from erosion. A sketch of an EAF is shown in Figure.

Figure Sketch of an electric arc furnace during operation, showing principal zones. The nature of zones and points of entry are approximate and change with time.

100 metric tons of steel are produced by an EAF process starting from the mixtures of DRI and scrap metal. DRI / Scrap metal ratio in the starting mixture is 1 / 3. The amount of the flux added into the raw mixture is 77 kg. The compositions of DRI, scrap metal, and flux mixture are given in Table 1.

Table 1. The compositions of DRI, scrap metal, and flux mixture

| DRI (mass %) | |

| Fetot | 92.19 |

| Ctot | 1.35 |

| SiO2 | 2.00 |

| Al2O3 | 0.70 |

| CaO | 0.80 |

| MgO | 0.40 |

| S | 0.005 |

| P | 0.010 |

| Other | rest |

| Scrap (mass %) | |

| Fe | 96.75 |

| C | 0.38 |

| Si | 0.80 |

| Mn | 0.50 |

| Cr | 0.50 |

| Ni | 0.40 |

| S | 0.005 |

| P | 0.005 |

| Other | rest |

| Flux (mass %) | |

| SiO2 | 2.57 |

| Al2O3 | 1.50 |

| CaO | 58.2 |

| MgO | 28.82 |

| P2O5 | 1.50 |

| LOI | 2.50 |

| C | 0.20 |

| Other | rest |

The metallization ratio of Fe (metallic Fe amount / Total Fe amount) in DRI is 91.6 %. The 92 wt. % of total C in DRI is found as Fe3C, and the rest of the carbon is found as element.

During the melting process, there are several reactions occurred. 81.3 wt. % of FeO in DRI reacts with Fe3C in DRI to form Fe and CO. 93.5 wt. % of remaining Fe3C in DRI reacts with O2 to form Fe and CO. The oxidation of free C in DRI with O2 gives CO. 2 wt. % of metallic Fe in DRI reacts with O2 to form FeO. 1.6 wt. % of Fe in scrap reacts with O2 to form FeO. 3.6 wt. % of C in scrap reacts with O2 to form CO. 22.8 wt. % of SiO2 in slag reacts with C in the electrode to form Si(steel) and CO.

DRI, the scrap metal and flux are charged into the arc furnace at 280, 320, and 60 C, respectively. The melting process is realized at 1700 C, and all the products (steel, slag, and gases) are obtained at this temperature.

a) Calculate the amount of DRI and Scrap metals used as raw material.

b) Calculate the composition of Steel (wt. %).

c) Calculate the amount and the composition of slag.

d) Calculate the required (or generated) energy for this process.

(Assumptions: The amount of air in the arc furnace is 3 m3 at STP. Other materials are inert, they go into the slag and can be ignored during energy calculation. LOI means loss of ignition. These materials go into the off-gas and can be ignored during energy calculation)

You can upload Word / Excel / HSC files of your homework.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started