Answered step by step

Verified Expert Solution

Question

1 Approved Answer

A calculation question of cost and management accounting ACLASS PLASTICS PTY. LTD. AClass Plastics Pty. Ltd., located in South Australia, is a low-cost producer of

A calculation question of cost and management accounting

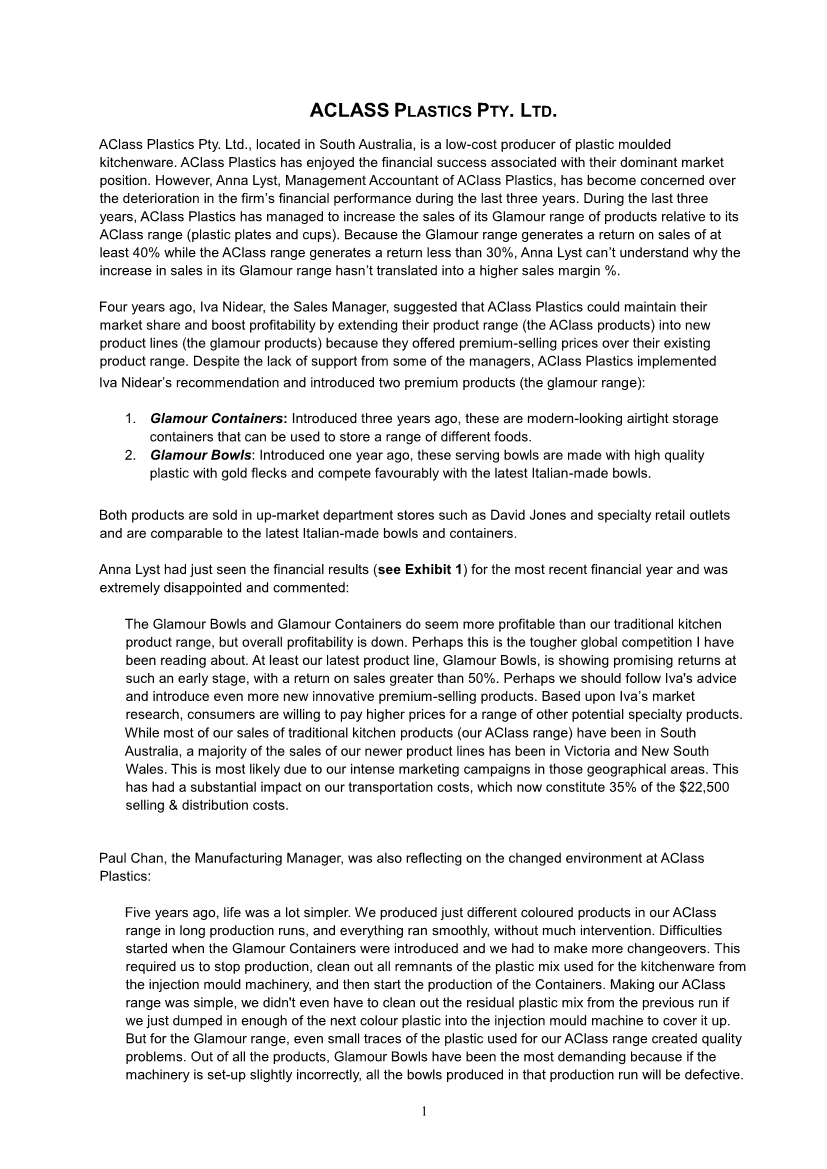

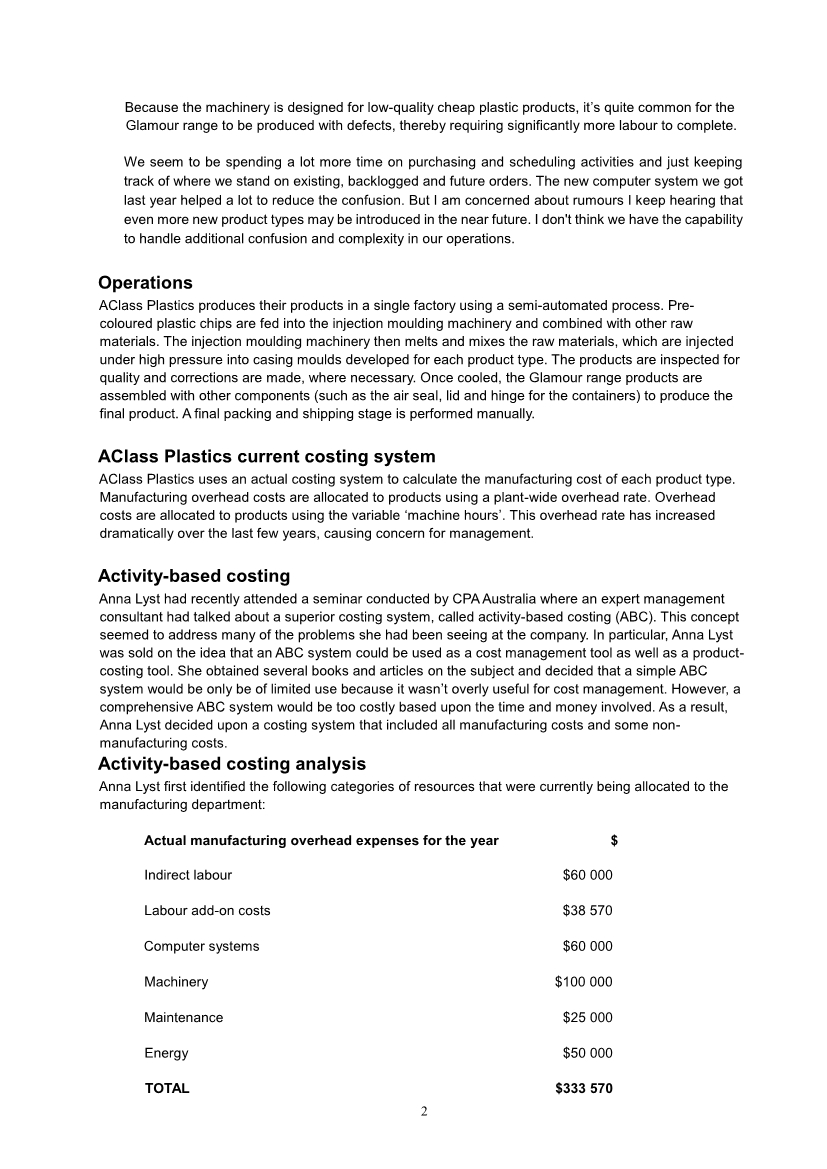

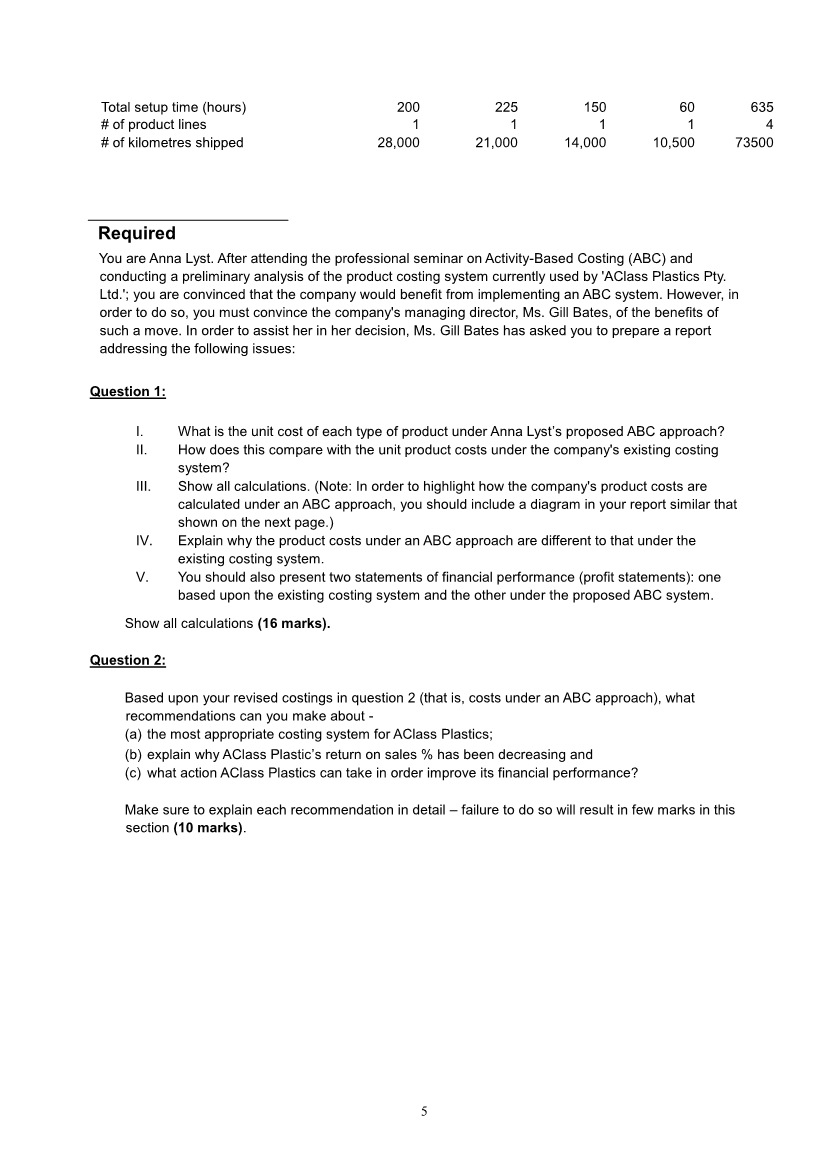

ACLASS PLASTICS PTY. LTD. AClass Plastics Pty. Ltd., located in South Australia, is a low-cost producer of plastic moulded kitchenware. AClass Plastics has enjoyed the financial success associated with their dominant market position. However, Anna Lyst, Management Accountant of AClass Plastics, has become concerned over the deterioration in the firm's financial performance during the last three years. During the last three years, AClass Plastics has managed to increase the sales of its Glamour range of products relative to its AClass range (plastic plates and cups). Because the Glamour range generates a return on sales of at least 40% while the AClass range generates a return less than 30%, Anna Lyst can't understand why the increase in sales in its Glamour range hasn't translated into a higher sales margin % Four years ago, Iva Nidear, the Sales Manager, suggested that AClass Plastics could maintain their market share and boost profitability by extending their product range (the AClass products) into new product lines (the glamour products) because they offered premium-selling prices over their existing product range. Despite the lack of support from some of the managers, AClass Plastics implemented Iva Nidear's recommendation and introduced two premium products (the glamour range) Glamour Containers: Introduced three years ago, these are modern-looking airtight storage containers that can be used to store a range of different foods Glamour Bowls: Introduced one year ago, these serving bowls are made with high quality plastic with gold flecks and compete favourably with the latest Italian-made bowls 1. 2. Both products are sold in up-market department stores such as David Jones and specialty retail outlets and are comparable to the latest Italian-made bowls and containers Anna Lyst had just seen the financial results (see Exhibit 1) for the most recent financial year and was extremely disappointed and commented The Glamour Bowls and Glamour Containers do seem more profitable than our traditional kitchen product range, but overall profitability is down. Perhaps this is the tougher global competition I have been reading about. At least our latest product line, Glamour Bowls, is showing promising returns at such an early stage, with a return on sales greater than 50%. Perhaps we should follow Iva's advice and introduce even more new innovative premium-selling products. Based upon Iva's market research, consumers are willing to pay higher prices for a range of other potential specialty products While most of our sales of traditional kitchen products (our AClass range) have been in South Australia, a majority of the sales of our newer product lines has been in Victoria and New South Wales. This is most likely due to our intense marketing campaigns in those geographical areas. This has had a substantial impact on our transportation costs, which now constitute 35% of the $22,500 selling & distribution costs Paul Chan, the Manufacturing Manager, was also reflecting on the changed environment at AClass Plastics: Five years ago, life was a lot simpler. We produced just different coloured products in our AClass range in long production runs, and everything ran smoothly, without much intervention. Difficulties started when the Glamour Containers were introduced and we had to make more changeovers. This required us to stop production, clean out all remnants of the plastic mix used for the kitchenware from the injection mould machinery, and then start the production of the Containers. Making our AClass range was simple, we didn't even have to clean out the residual plastic mix from the previous run if we just dumped in enough of the next colour plastic into the injection mould machine to cover it up But for the Glamour range, even small traces of the plastic used for our AClass range created quality problems. Out of all the products, Glamour Bowls have been the most demanding because if the machinery is set-up slightly incorrectly, all the bowls produced in that production run will be defectiveStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started