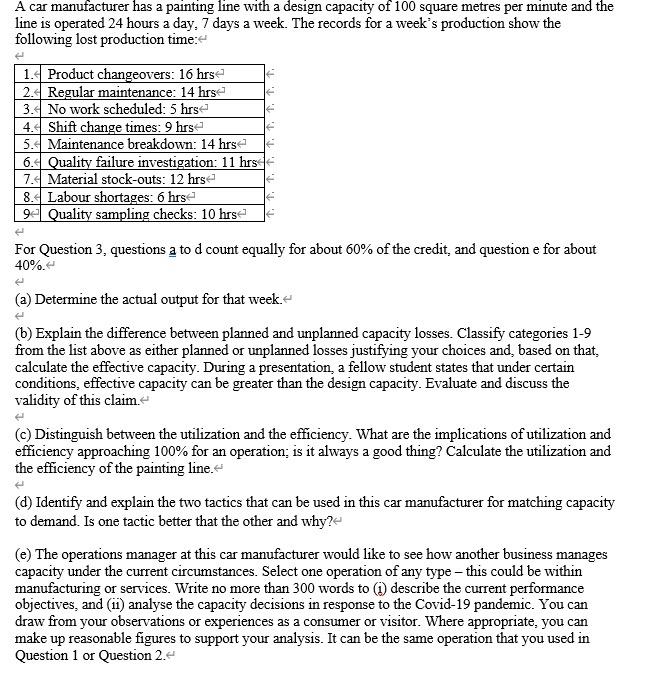

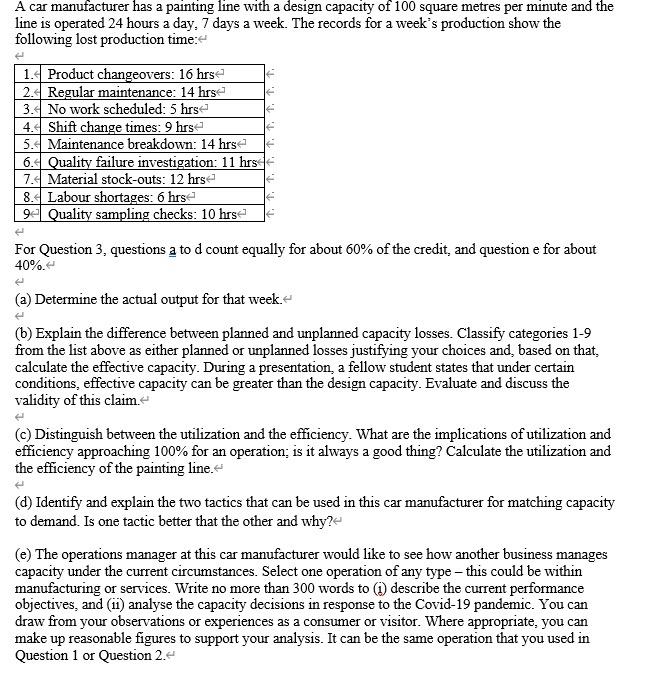

A car manufacturer has a painting line with a design capacity of 100 square metres per minute and the line is operated 24 hours a day, 7 days a week. The records for a week's production show the following lost production time: 1. Product changeovers: 16 hrs 2. Regular maintenance: 14 hrse 3. No work scheduled: 5 hrs 4. Shift change times: 9 hrs 5. Maintenance breakdown: 14 hrs- 6. Quality failure investigation: 11 hrs 7. Material stock-outs: 12 hrs 8. Labour shortages: 6 hrs- 9- Quality sampling checks: 10 hrs For Question 3, questions a to d count equally for about 60% of the credit, and question e for about 40%. (a) Determine the actual output for that week (b) Explain the difference between planned and unplanned capacity losses. Classify categories 1-9 from the list above as either planned or unplanned losses justifying your choices and based on that. calculate the effective capacity. During a presentation, a fellow student states that under certain conditions, effective capacity can be greater than the design capacity. Evaluate and discuss the validity of this claim.- (c) Distinguish between the utilization and the efficiency. What are the implications of utilization and efficiency approaching 100% for an operation, is it always a good thing? Calculate the utilization and the efficiency of the painting line. (d) Identify and explain the two tactics that can be used in this car manufacturer for matching capacity to demand. Is one tactic better that the other and why? (e) The operations manager at this car manufacturer would like to see how another business manages capacity under the current circumstances. Select one operation of any type - this could be within manufacturing or services. Write no more than 300 words to describe the current performance objectives, and (11) analyse the capacity decisions in response to the Covid-19 pandemic. You can draw from your observations or experiences as a consumer or visitor. Where appropriate, you can make up reasonable figures to support your analysis. It can be the same operation that you used in Question 1 or Question 2. A car manufacturer has a painting line with a design capacity of 100 square metres per minute and the line is operated 24 hours a day, 7 days a week. The records for a week's production show the following lost production time: 1. Product changeovers: 16 hrs 2. Regular maintenance: 14 hrse 3. No work scheduled: 5 hrs 4. Shift change times: 9 hrs 5. Maintenance breakdown: 14 hrs- 6. Quality failure investigation: 11 hrs 7. Material stock-outs: 12 hrs 8. Labour shortages: 6 hrs- 9- Quality sampling checks: 10 hrs For Question 3, questions a to d count equally for about 60% of the credit, and question e for about 40%. (a) Determine the actual output for that week (b) Explain the difference between planned and unplanned capacity losses. Classify categories 1-9 from the list above as either planned or unplanned losses justifying your choices and based on that. calculate the effective capacity. During a presentation, a fellow student states that under certain conditions, effective capacity can be greater than the design capacity. Evaluate and discuss the validity of this claim.- (c) Distinguish between the utilization and the efficiency. What are the implications of utilization and efficiency approaching 100% for an operation, is it always a good thing? Calculate the utilization and the efficiency of the painting line. (d) Identify and explain the two tactics that can be used in this car manufacturer for matching capacity to demand. Is one tactic better that the other and why? (e) The operations manager at this car manufacturer would like to see how another business manages capacity under the current circumstances. Select one operation of any type - this could be within manufacturing or services. Write no more than 300 words to describe the current performance objectives, and (11) analyse the capacity decisions in response to the Covid-19 pandemic. You can draw from your observations or experiences as a consumer or visitor. Where appropriate, you can make up reasonable figures to support your analysis. It can be the same operation that you used in Question 1 or Question 2