Answered step by step

Verified Expert Solution

Question

1 Approved Answer

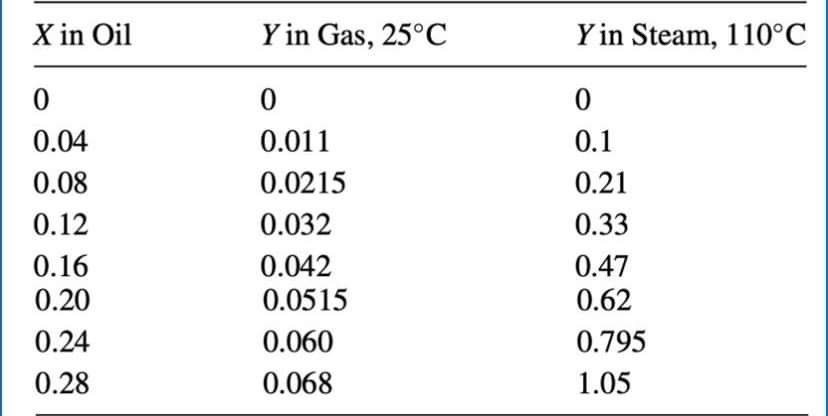

A chemical separation plant utilizes an absorber and stripper.Target Recovery:Ninety percent ( 9 0 % ) of Hydrocarbon X must be removed from the incoming

A chemical separation plant utilizes an absorber and stripper.Target Recovery:Ninety percent of Hydrocarbon X must be removed from the incoming gas stream. This gas stream initially contains a specific concentration of Hydrocarbon X moles per mole of Xfree gasFeed Streams:Gas Stream: The gas stream entering the absorber contains the Hydrocarbon X we want to capture. The concentration is quantified as a ratio of moles of Hydrocarbon X to moles of all other components in the gas excluding Hydrocarbon X This ratio is Oil Stream: The oil enters the top of the absorber This oil initially has a low concentration of Hydrocarbon X moles per mole of pure oilProduct Benzenerich Oil: The exiting liquid stream from the absorber has a higher concentration of Hydrocarbon X moles per mole of pure oil.Vapors are condensed, separated, and removed.Conditions:The entire process operates at a constant temperature deg C or deg FFor the stripping stage, a hightemperature steam benzenefree is used to remove the Hydrocarbon X from the rich oil. The stripping stage operates at a higher temperature deg CThe ratio of the flow rate of the pure oil entering the absorber to the flow rate of the benzenefree steam is Molecular weight MW of the oil: Molecular weight of Hydrocarbon X: Molecular weight of the nonHydrocarbon X gas components: Determine the number of theoretical stages.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started