Answered step by step

Verified Expert Solution

Question

1 Approved Answer

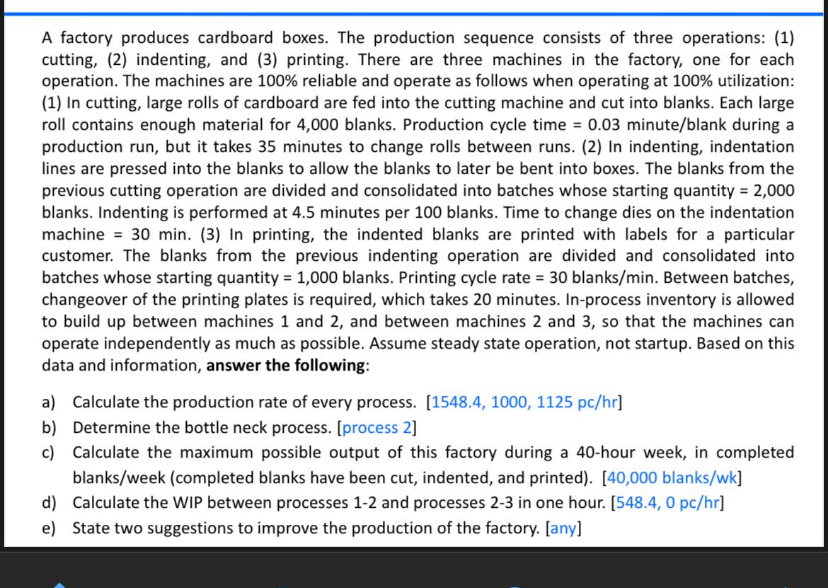

A factory produces cardboard boxes. The production sequence consists of three operations: ( 1 ) cutting, ( 2 ) indenting, and ( 3 ) printing.

A factory produces cardboard boxes. The production sequence consists of three operations: cutting, indenting, and printing. There are three machines in the factory, one for each operation. The machines are reliable and operate as follows when operating at utilization: In cutting, large rolls of cardboard are fed into the cutting machine and cut into blanks. Each large roll contains enough material for blanks. Production cycle time minuteblank during a production run, but it takes minutes to change rolls between runs. In indenting, indentation lines are pressed into the blanks to allow the blanks to later be bent into boxes. The blanks from the previous cutting operation are divided and consolidated into batches whose starting quantity blanks. Indenting is performed at minutes per blanks. Time to change dies on the indentation machine min. In printing, the indented blanks are printed with labels for a particular customer. The blanks from the previous indenting operation are divided and consolidated into batches whose starting quantity blanks. Printing cycle rate blanks Between batches, changeover of the printing plates is required, which takes minutes. Inprocess inventory is allowed to build up between machines and and between machines and so that the machines can operate independently as much as possible. Assume steady state operation, not startup. Based on this data and information, answer the following:

a Calculate the production rate of every process.

b Determine the bottle neck process. process

c Calculate the maximum possible output of this factory during a hour week, in completed blanksweek completed blanks have been cut, indented, and printed blankswk

d Calculate the WIP between processes and processes in one hour. pchr

e State two suggestions to improve the production of the factory. any

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started